Comfortable hollow outsole

A hollow bottom shoe technology, applied to footwear, shoe soles, insoles, etc., can solve the problems of increased production difficulty, uncomfortable wearing, difficult to fit, etc., and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

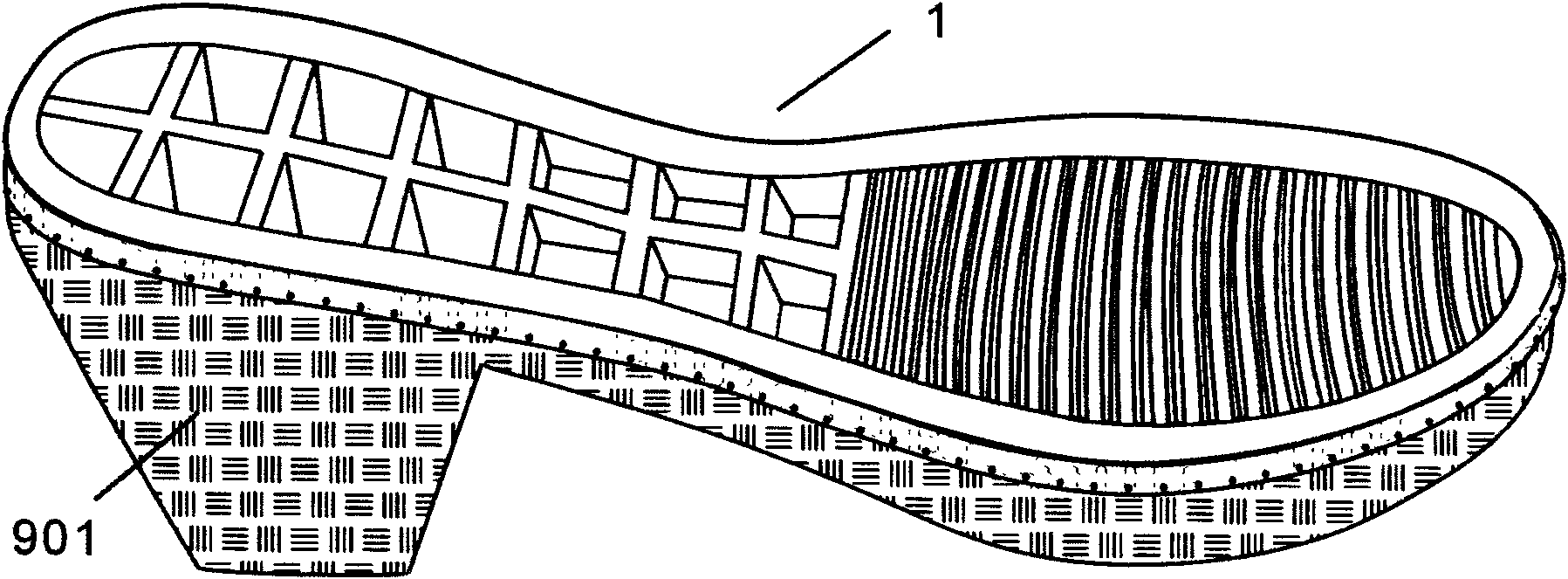

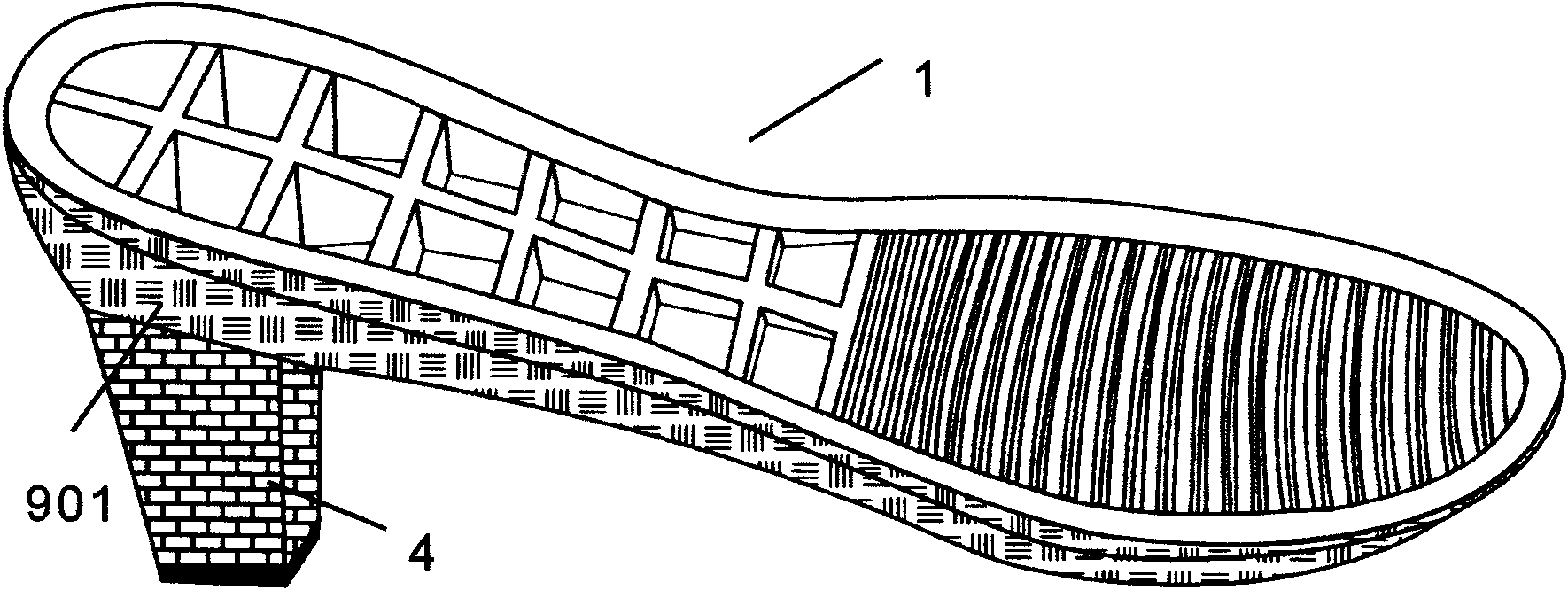

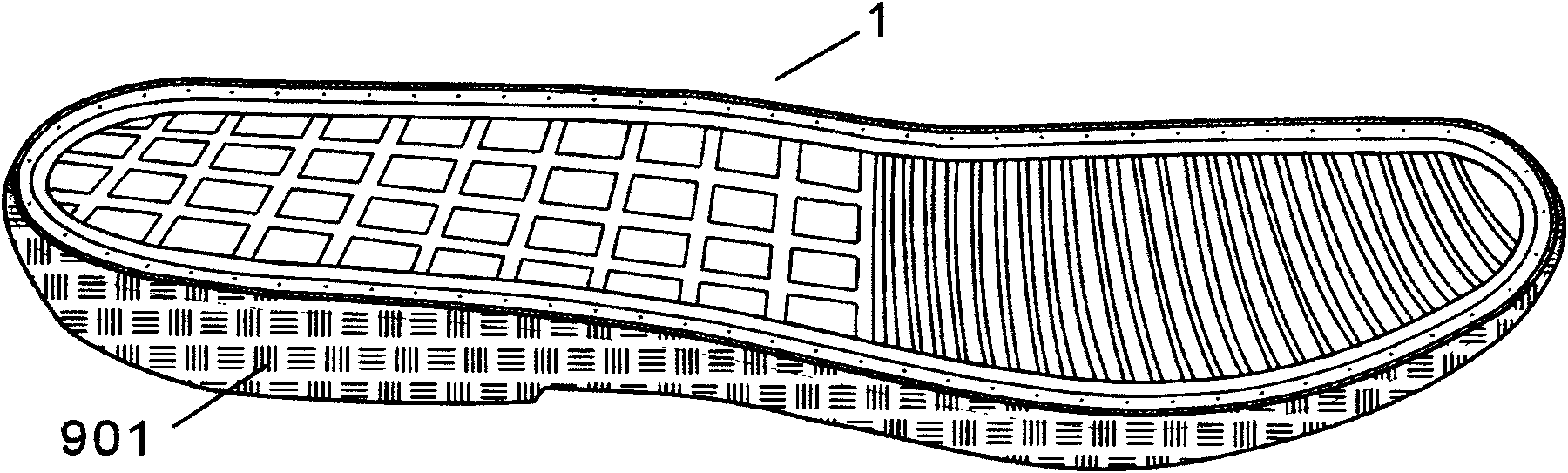

[0087] see Figure 8 to Figure 55 As shown, a comfortable hollow outsole shoe includes a shoe main body 100. The shoe main body 100 is composed of a vamp 20, an insole 30 and a sole. The sole includes a shoe outsole 1, which is a hollow outsole.

[0088] There are two situations for further improvement.

[0089] In the first case, the shoe outsole 1 is provided with a stabilizing body 90 matching the shape of the shoe outsole 1 . This scheme includes the scheme that only the stabilizer 90 is set in the outsole 1 of the shoe, such as Figure 9 to Figure 15 , Figure 22 to Figure 26 , Figure 37 to Figure 39 ,in Figure 26 , Figure 37 to Figure 39 The solid body 90 in the middle is also provided with a large bottom waist iron 6,

[0090] and Figure 16 to Figure 21 , Figure 27 to Figure 36 A further improvement is that there are several material guide holes 904 on the heel position 901 of the stabilizer 90 or from the heel position 901 to the forefoot position 902 or o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com