Corneal suture nail based on shape memory alloy

A technology of memory alloy and suture staples, which is applied in the field of corneal suture staples, can solve problems such as difficulty in uniform corneal tension, limited operating space, and uneven corneal tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

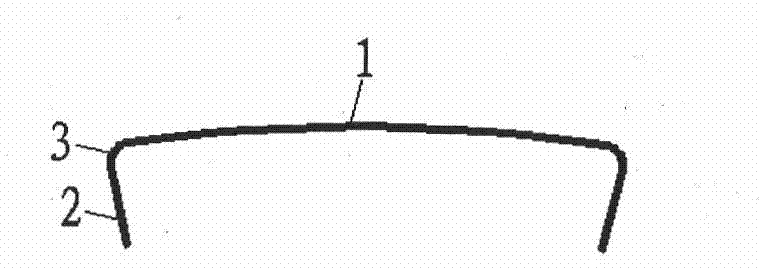

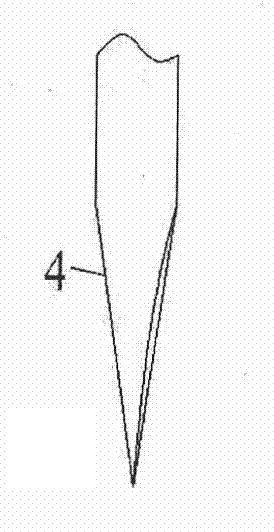

[0021] Such as figure 1 As shown, before the phase transition of the shape memory alloy-based corneal staple in the present invention, one end of the corneal slice needs to be held with medical tweezers, and the waist 1 of the corneal staple must be held with another pair of tweezers, close to the legs of the staple and At the junction 3 of the waist, utilize the triangular edge of the corneal staple leg tip 7 to pierce the corneal implant bed, and then pierce the other end of the corneal staple into the corneal slice.

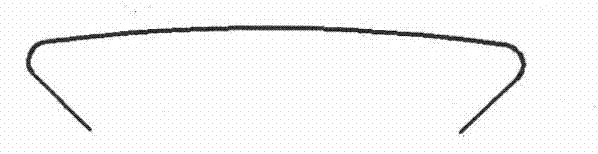

[0022] When the corneal staple penetrates into the cornea, the temperature gradually tends to be consistent with the corneal temperature, and occurs when the phase transition temperature reaches 30 degrees figure 2 In the variant shown, the angle between the two legs of the corneal staple is approximately 90 degrees, compressing the corneal implant bed and corneal slice together for healing.

[0023] In the present invention, it is necessary to ensure that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com