Leakproof casting box

A casting and leak-proof technology, which is applied in the direction of mold boxes, casting molding equipment, metal processing equipment, etc., can solve the problems of local warping, fire escape, lax fitting, etc., and achieve the goal of avoiding steel leakage and leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

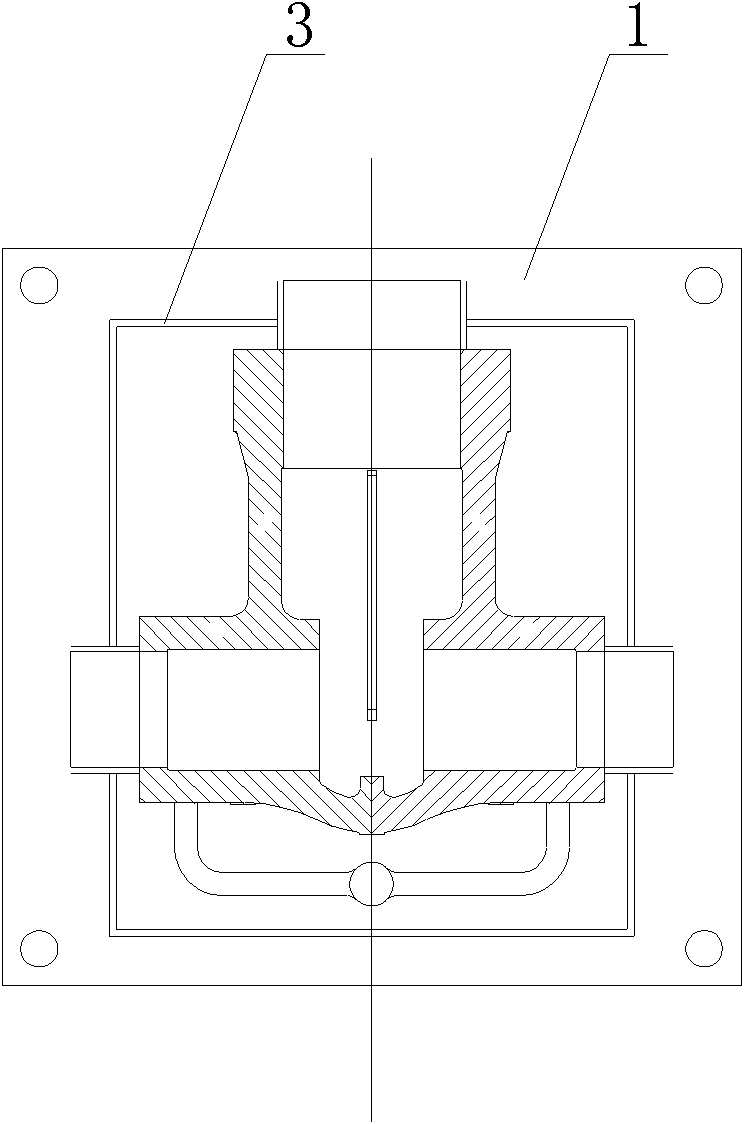

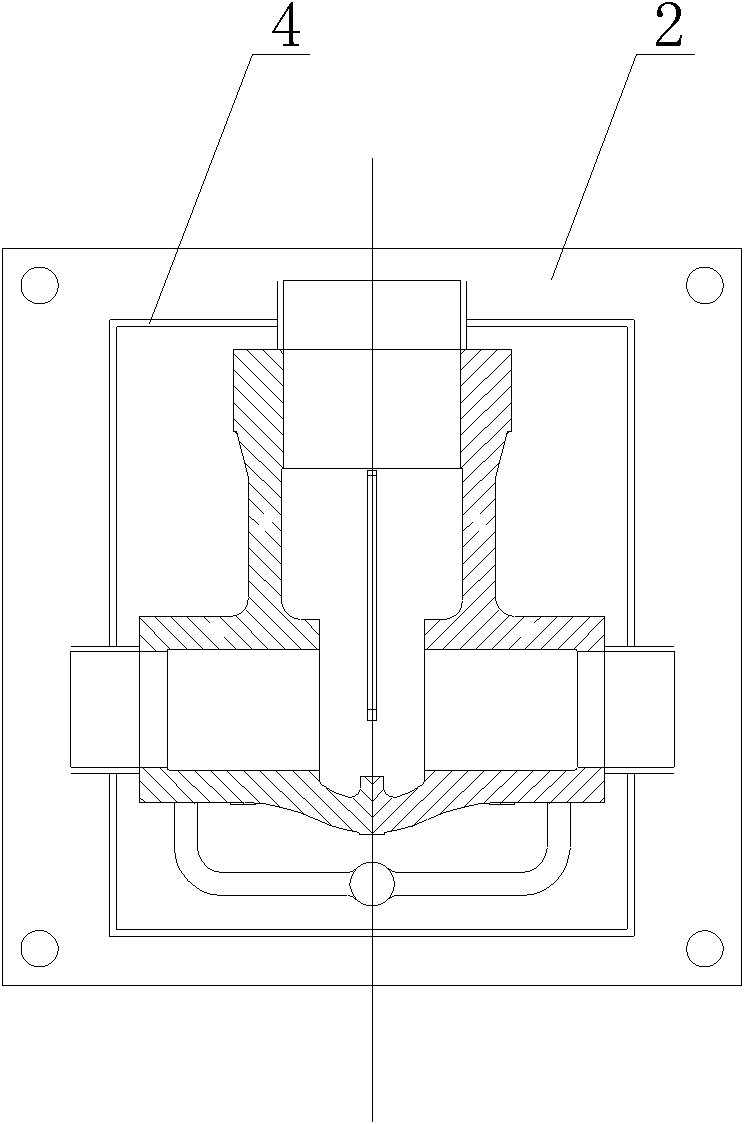

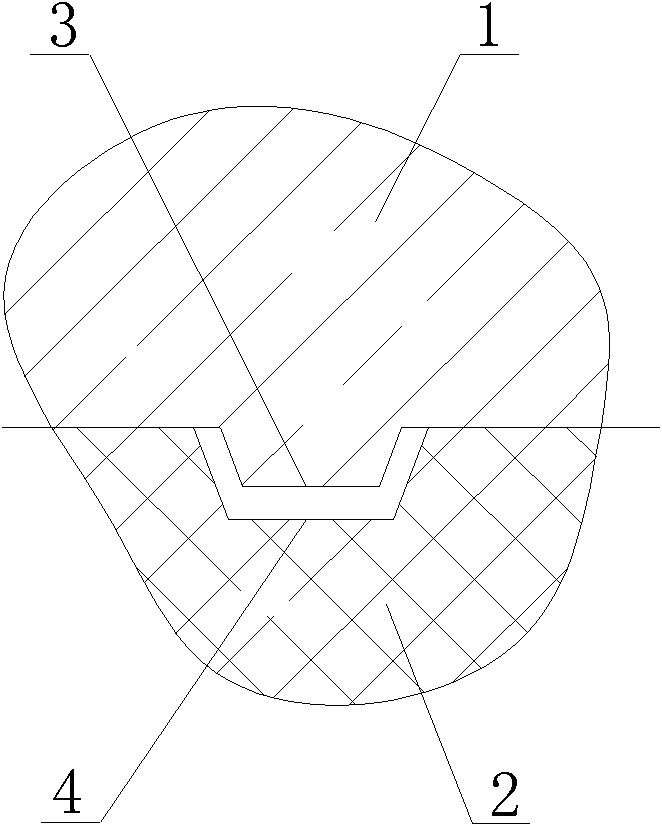

[0012] Such as figure 1 , figure 2 and image 3 Shown, a kind of leak-proof mold box, comprises upper box 1 and lower box 2, the parting surface of described upper box 1 is provided with boss 3, and the parting surface of described lower box 2 is provided with convex platform. Table 3 corresponds to groove 4. The ring of the boss 3 is arranged on the parting surface of the upper case 1 . The groove 4 ring is arranged on the parting surface of the lower case 2 . The boss 3 cooperates with the groove 4. If there is molten steel flowing out and encountering such a structure, it will be blocked and cannot continue to flow outward. Some thin molten steel layers left on the parting surface will cool rapidly and be more sealed, which prevents The seepage of molten steel in the box is avoided, and the formation of steel breakout is avoided.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap