Filter screen two-level self-cleaning filter

A self-cleaning and filter technology, which is used in mobile filter element filters, filtration separation, chemical instruments and methods, etc. Can not be removed, affecting the filtration efficiency and other problems, to achieve the effect of convenient operation and maintenance, large filtration area, and simplified overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

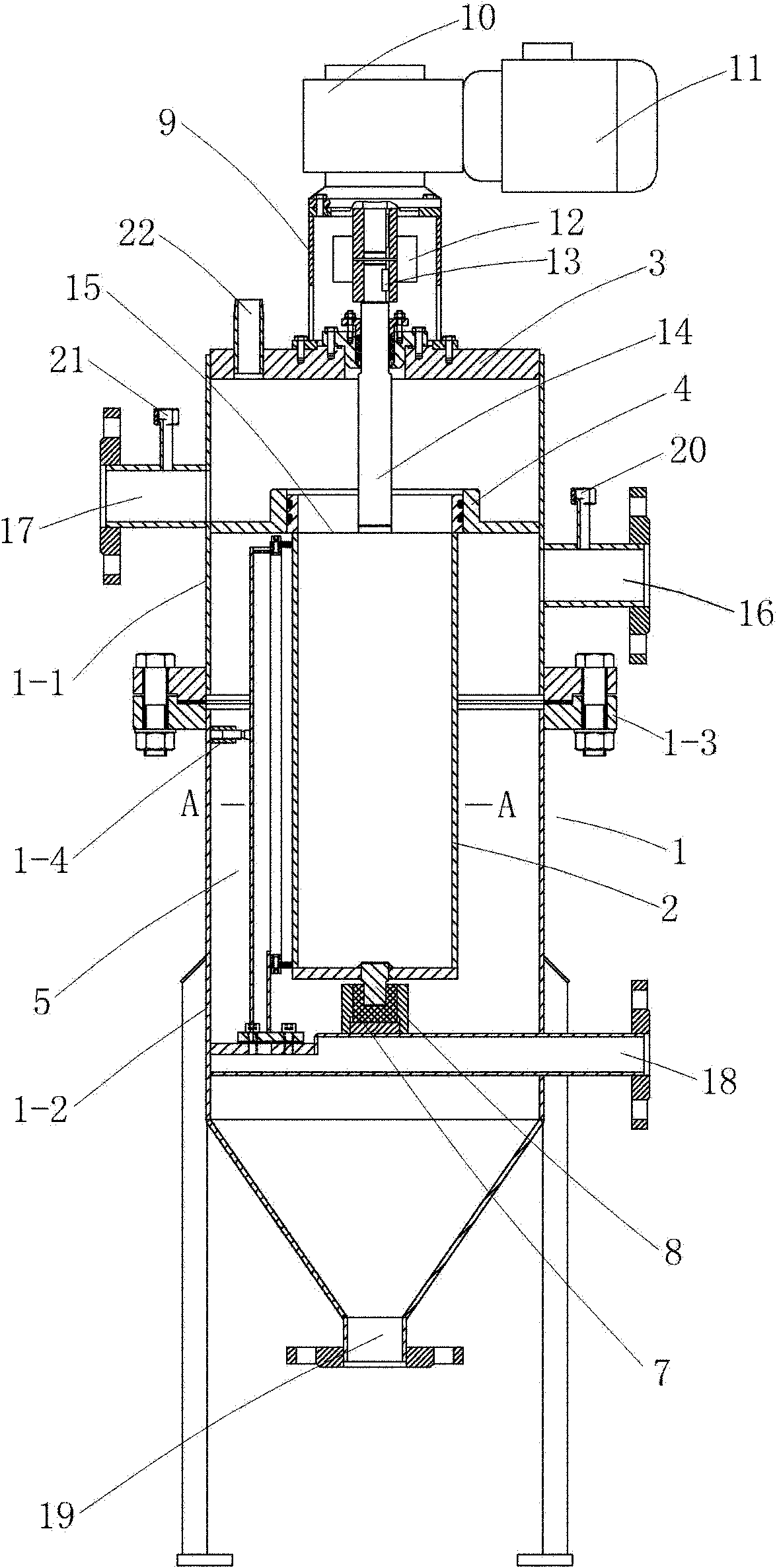

[0027] Example: figure 1 As shown, in the filter of this embodiment, the main body is a cylinder 1 with a primary sewage outlet 19 at the bottom, and a filtrate outlet 17 is provided on the upper side of the cylinder; the top of the cylinder 1 is sealed by an end cap 3, and the end cap There is an exhaust port 22 on the top; in the specific setting, the cylinder body 1 is composed of the upper cylinder body 1-1 and the lower cylinder body 1-2, and the matching parts of the upper cylinder body and the lower cylinder body are equipped with a large flange 1 -3. The two large flanges are connected by bolts and nuts, and there is a large gasket seal between the two large flanges. A sliding bearing 7 is fixed inside the cylinder body 1. The sliding bearing is located on the axis of the filter cartridge 2 and below the filter cartridge. A short shaft 8 inserted into the sliding bearing is fixed at the bottom of the filter cartridge. The sliding bearing 7 forms a pair of Describe the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com