Double-sided-scanning type irradiance testing jig

A double-sided scanning and irradiance technology, which is applied in the field of irradiance test racks, can solve the problems of inability to accurately determine the UV irradiance of the UV aging test box, low reliability of test results, and low measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

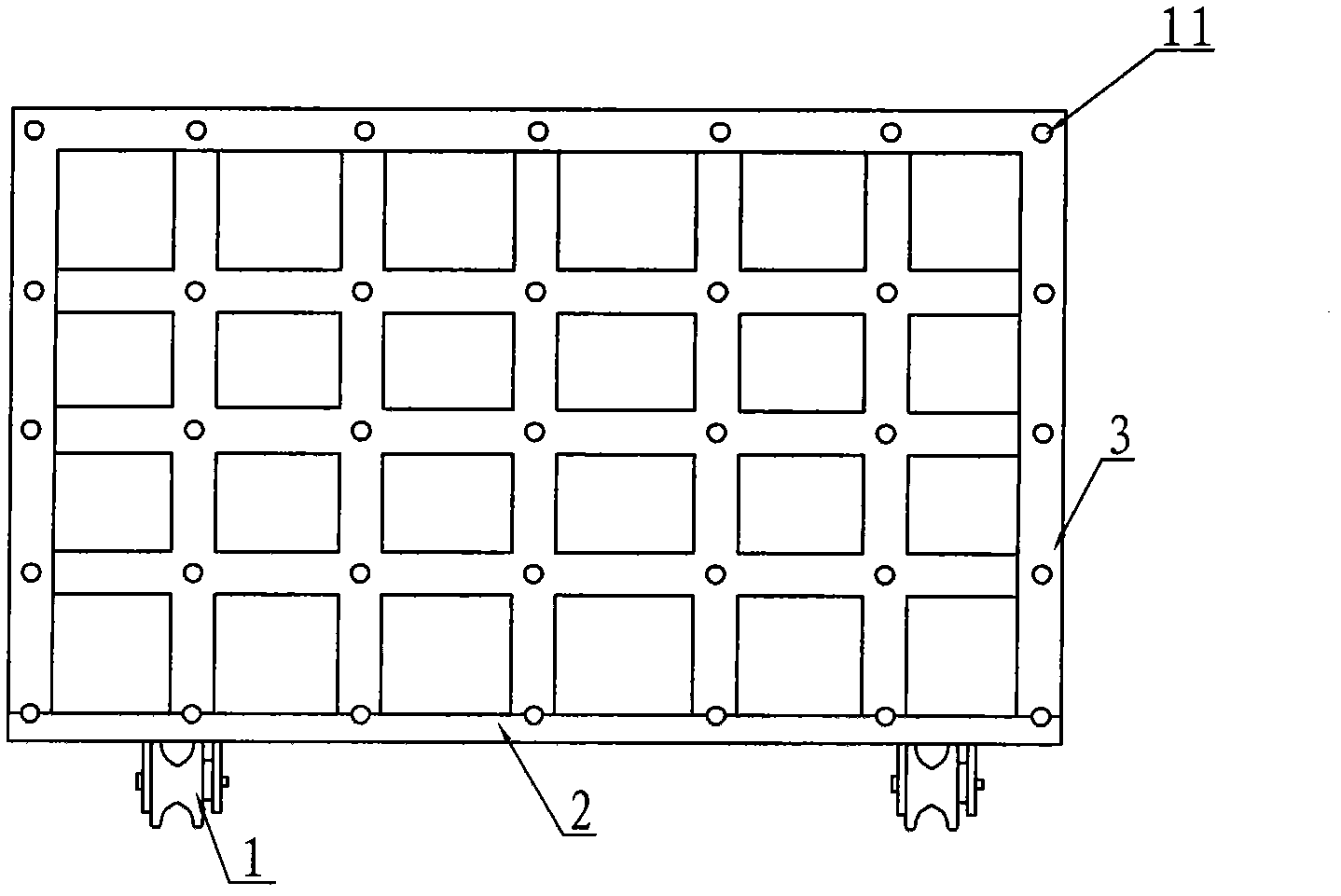

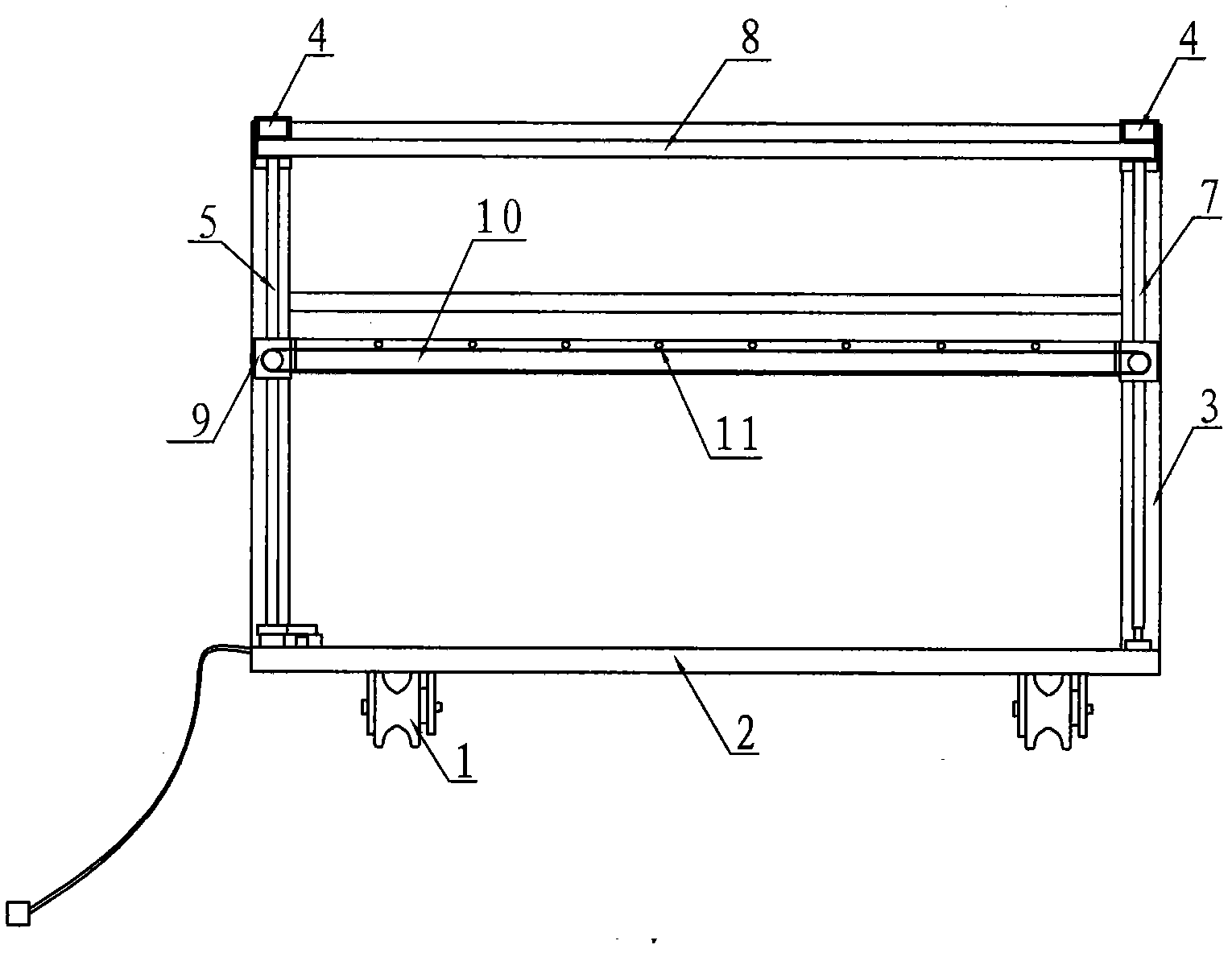

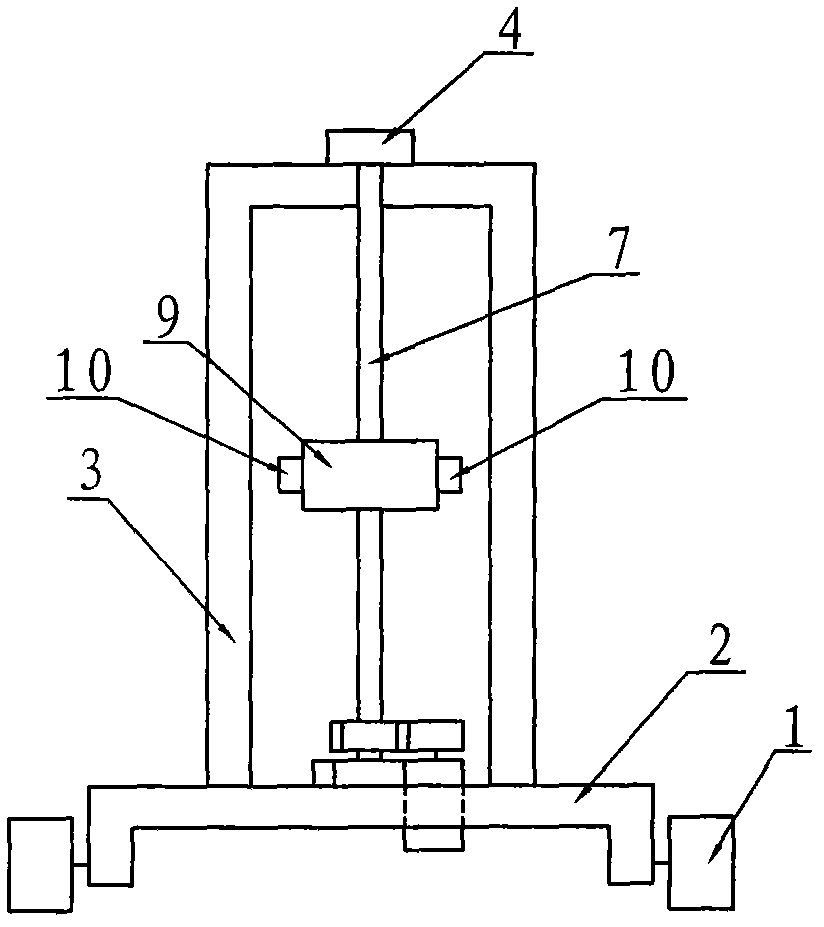

[0015] Embodiment 1: the double-sided scanning irradiance test frame, such as figure 2 , image 3 with Figure 4 As shown, it includes roller 1, bottom frame 2, vertical frame 3, bearing seat 4, left screw rod 5, timing pulley 6, right screw rod 7, timing belt 8, mobile installation block 9, horizontal rod 10, spoke The illuminance probe 11 and the lifting motor 12, the vertical frame 3 are fixed on the upper end surface of the bottom frame 2, and four rollers 1 are installed on the lower end surface of the bottom frame 2. Corresponding guide groove, the two ends of left screw mandrel 5 and right screw mandrel 7 are all fixed on the vertical frame 3 by bearing seat 4, and left screw mandrel 5 and right screw mandrel 7 are parallel, and perpendicular to bottom frame 2, on the left The upper ends of the screw mandrel 5 and the right screw mandrel 7 are equipped with a synchronous pulley 6 at the same height, and the two synchronous pulleys 6 are connected by a synchronous bel...

Embodiment 2

[0016] Embodiment 2: In Embodiment 1, the lifting motor 12 drives the right screw mandrel 7 to rotate through the driving gear 13 and the driven gear 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com