Radial and axial multi-vibrator ultrasonic linear motor and operating method thereof

A linear motor and ultrasonic technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problems of slow speed, small thrust, large loss, etc., and achieve the goal of using The effect of long life, high thrust and low work loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

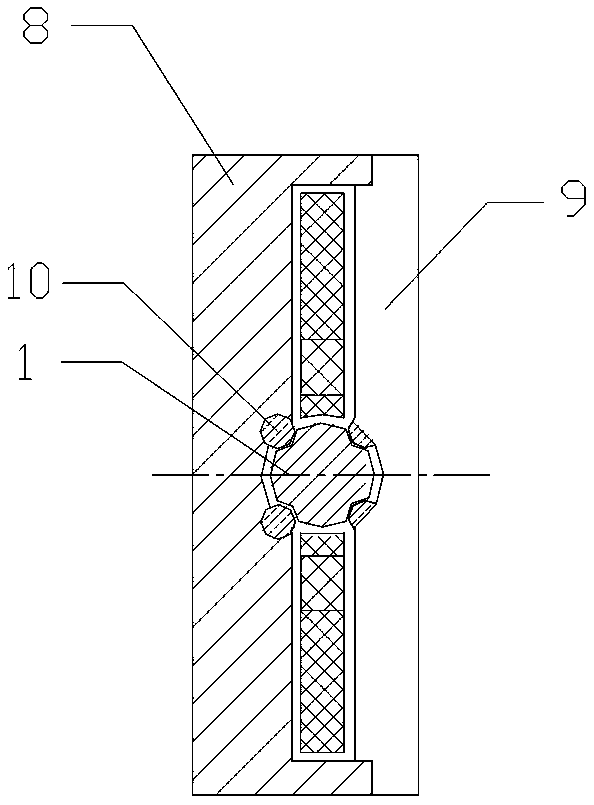

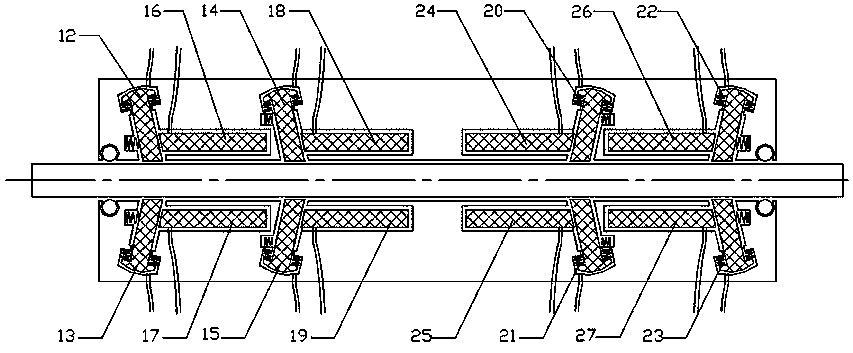

[0039] Such as figure 1 and 2As shown, the present invention is mainly composed of a motor stator with a central hole and a motor mover 1 penetrating through the central hole. The motor stator is mainly composed of a stator housing and a radial vibrator disposed on the stator housing. Groove and axial vibrator groove, the stator housing is mainly composed of stator housing A8 and stator housing B9 fastened together, the radial vibrator groove and axial vibrator groove are formed along the center hole respectively Radial setting and axial setting; one end of the radial vibrator groove communicates with the central hole, and the left or right side of the radial vibrator groove is provided with a spring groove communicating with it; the axial vibrator groove is located The right side or the left side of the radial vibrator groove is connected with the radial vibrator groove; the radial vibrator is arranged in the radial vibrator groove, the axial vibrator is arranged in the axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com