Pipeline connecting component

A technology for connecting components and pipes, applied in flange connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problems of low installation efficiency, easy loss of connecting bolts, etc., and achieve the effect of improving installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

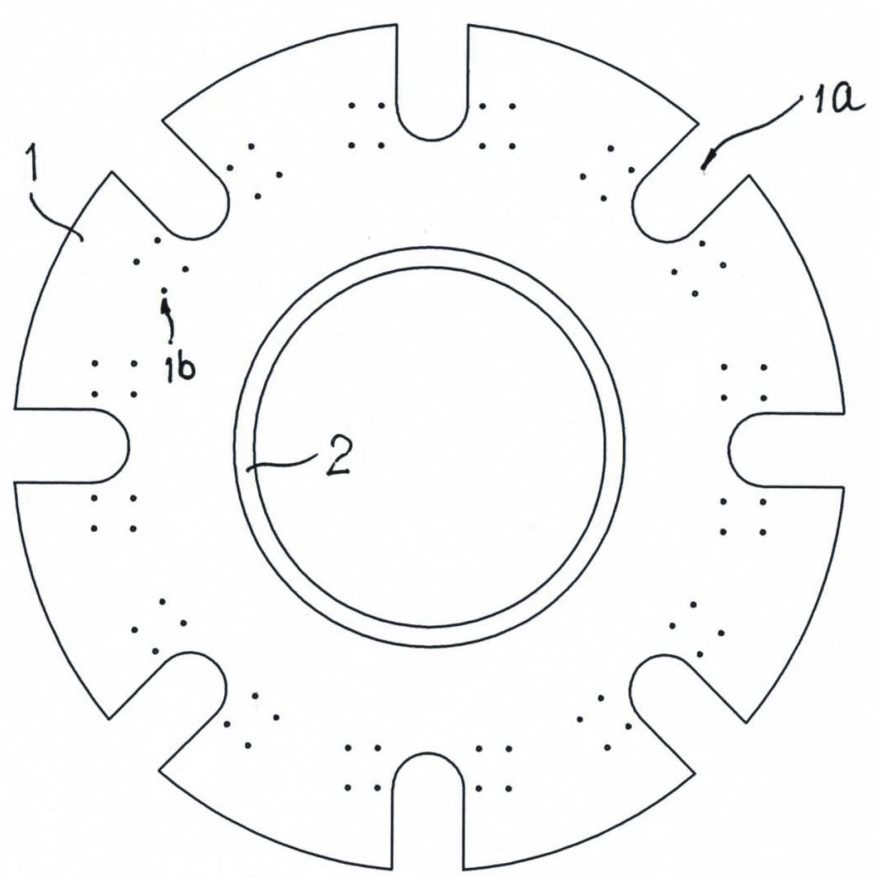

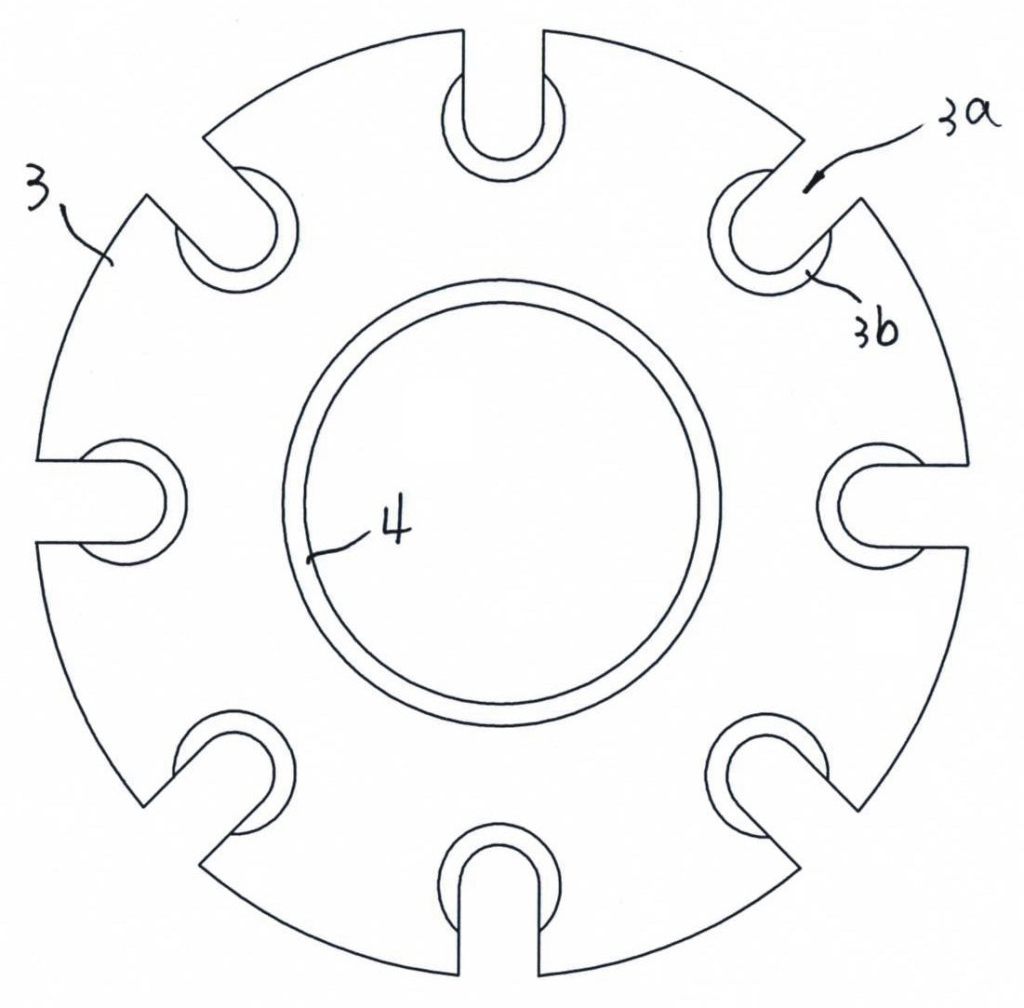

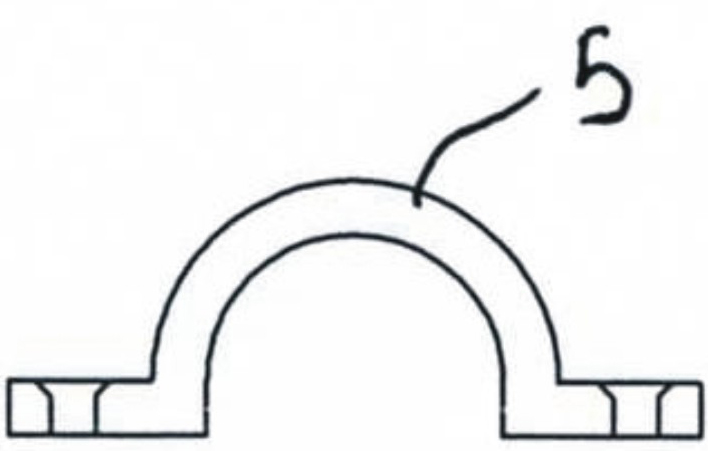

[0017] Figure 8 Shown, the present invention comprises the 1st steel pipe 2, the 1st flange 1 welded on the 1st steel pipe, the 2nd steel pipe 4, the 2nd flange 3 welded on the 2nd steel pipe; The 1st flange 1 There are 8 opening holes corresponding to the second flange 3, and a T-shaped bolt 6 is provided at the position of each opening 1a on the outer surface of the first flange 1: two clamps 5 are clamped respectively Set on the left and right ends of the horizontal section of the T-bolt, the two hoops 5 are fixed on the first flange through countersunk screws. (see Figure 1-7 ).

[0018] see Figure 8 , after assembly, the adjacent surface of the two flanges is called the inner surface, and the non-adjacent surface of the two flanges is called the outer surface. see figure 1 , figure 2 , the opening hole on the flange refers to the opening on the basis of the opening on the original flange and expands outward until the outer edge of the flange to form an opening s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com