Case-reasoning-based molten steel temperature prediction method

A technology of molten steel temperature prediction and molten steel temperature, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of long retrieval time and no results, shorten the search time, overcome the long training time, Overcoming effects not suitable for online applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

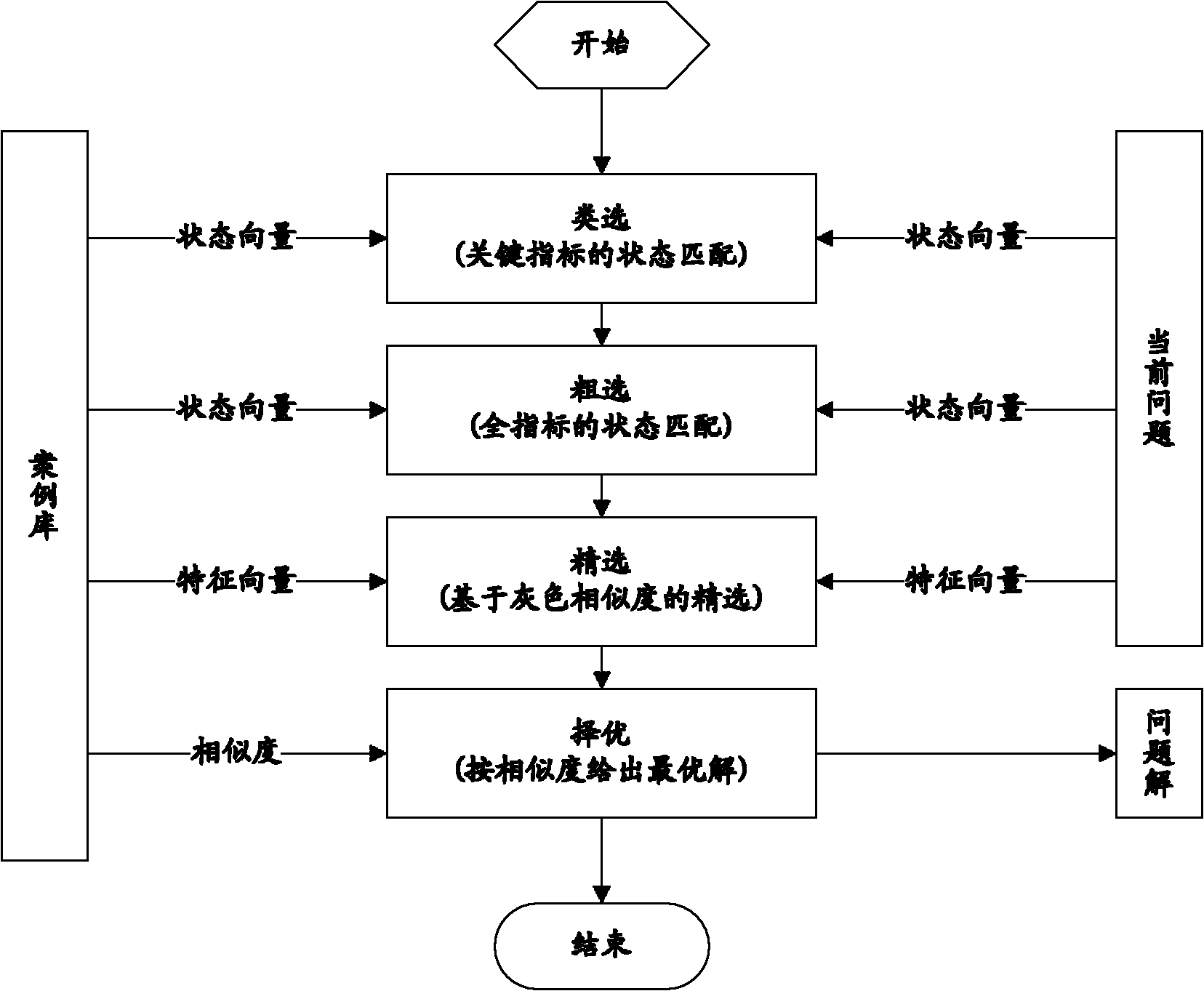

[0031] This embodiment provides a method for predicting molten steel temperature based on case reasoning, such as figure 1 shown, including the following steps:

[0032] Step 1: Establish a case library of molten steel temperature.

[0033] The case library is used to store the value of the influencing factors of the molten steel temperature and the molten steel temperature, and the value of each molten steel temperature influencing factor and the record of the molten steel temperature are called cases, in the form . The maintenance of the case base adopts appropriate forgetting and retention strategies to keep the adaptability of the case base.

[0034] Step 2: Define the current problem and problem solution.

[0035] The current problem is a record of values of influencing factors of molten steel temperature. The problem solution is the predicted temperature of the current problem.

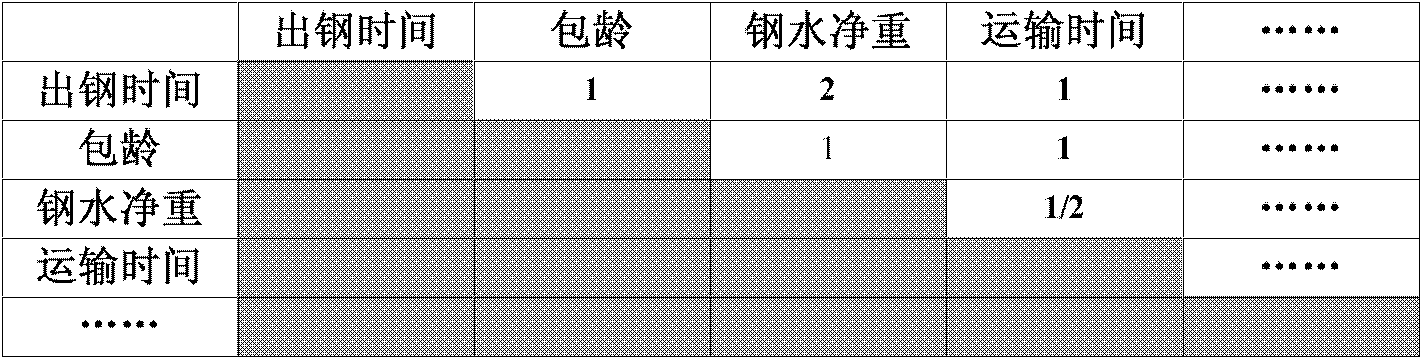

[0036] Step 3: Classify the case sets in the case base according to the key state vect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com