Centering device and centering method

A technology of centering device and eccentricity, which is used in positioning device, clamping, supporting and other directions to achieve the effect of saving space, improving durability and realizing correction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

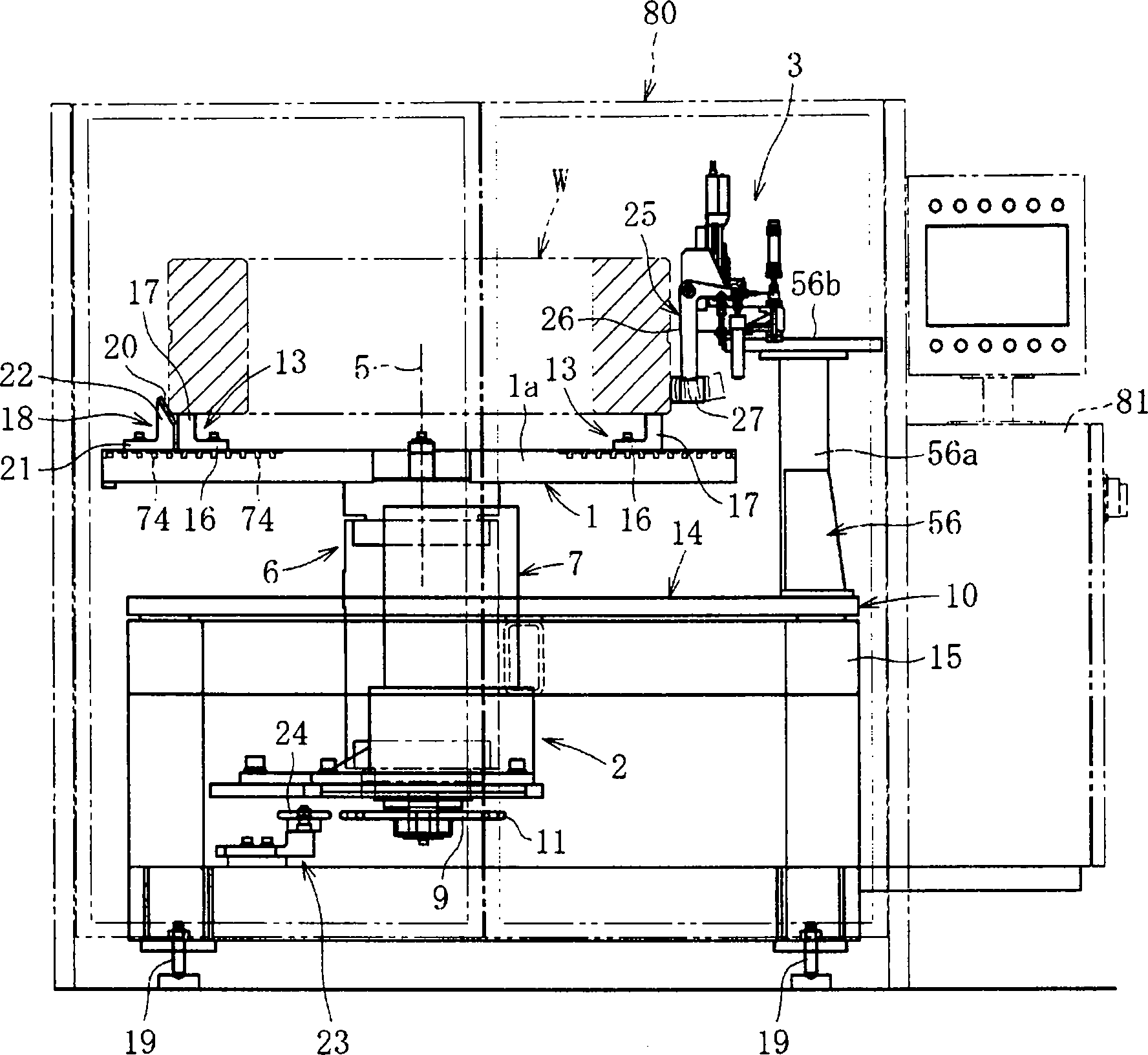

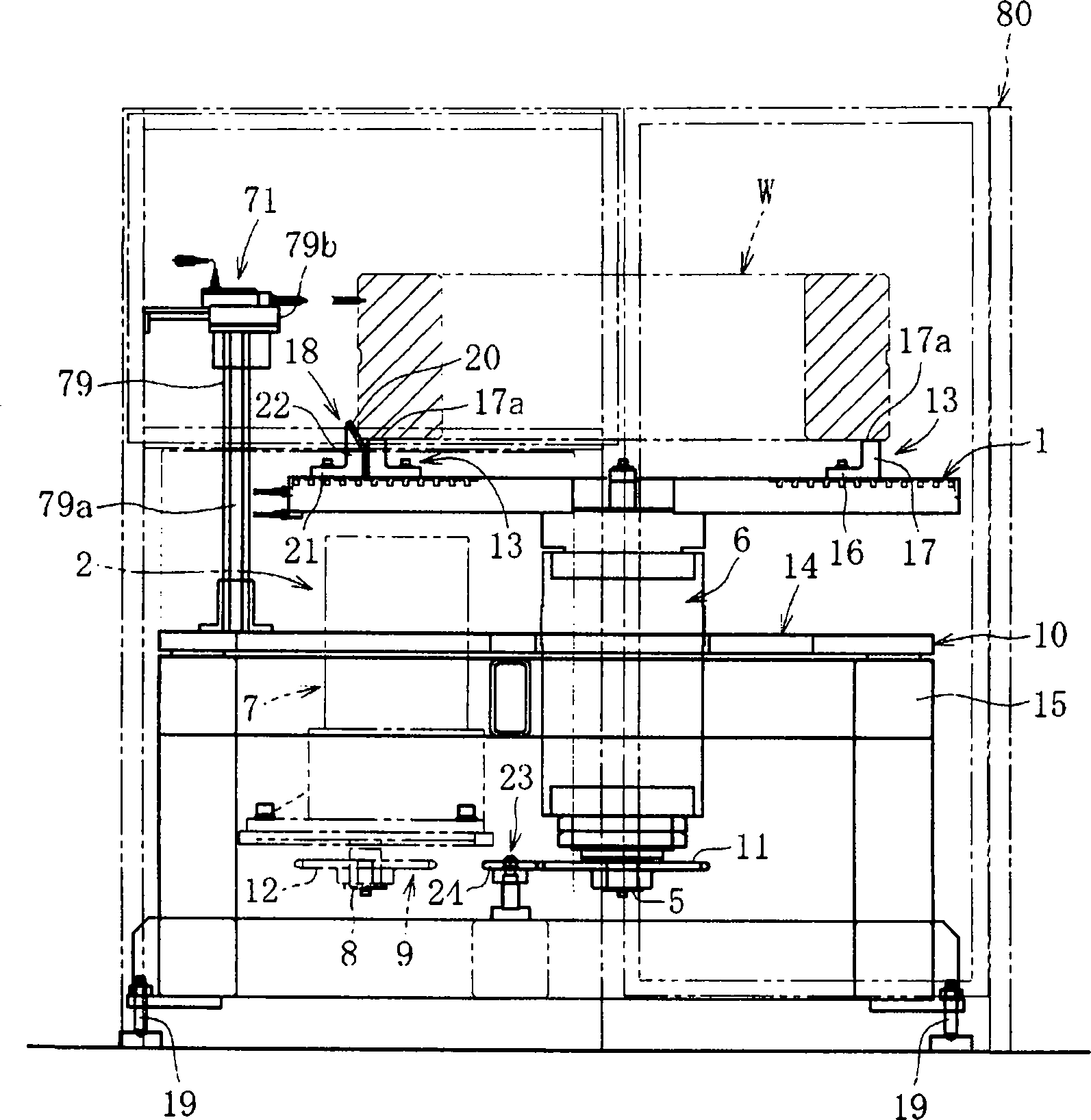

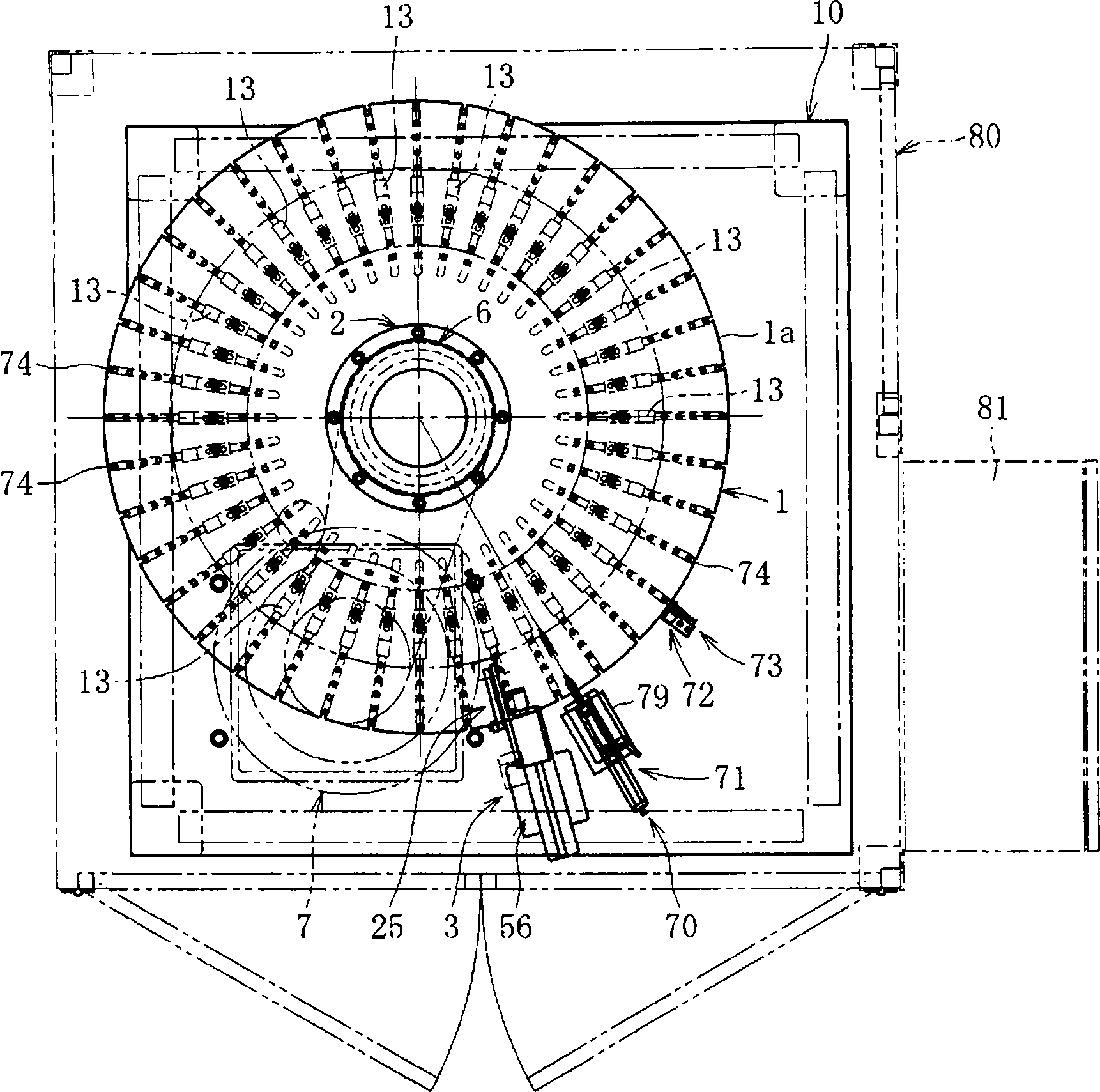

[0043] based on the following Figure 1 to Figure 16 Embodiments of the present invention will be described.

[0044] Figure 1 ~ Figure 3 The centering device of the present invention is shown. The centering device includes: a rotary table 1 on which a workpiece W is placed; a drive unit 2 for rotating the rotary table 1 around its axis; Inner ring or outer ring, etc.) The impact force imparting structure 3 that imparts impact force.

[0045] The drive unit 2 includes: a bearing structure 6 that supports the center shaft 5 of the turntable 1 so as to be rotatable about its axis, a drive motor 7 , an output shaft 8 of the drive motor 7 and the center shaft 5 Linkage members 9 linked together. The interlocking member 9 includes: a sprocket 11 mounted on the central shaft 5 of the turntable 1; a sprocket 12 mounted on the output shaft 8 of the driving motor 7; and a chain wound around the sprockets 11, 12. (Illustration omitted). The bearing structure 6 and the driving moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com