Track type slag pot overturning trolley device and method thereof

A tipping device and track-type technology, which is applied in the field of waste heat recovery and pretreatment of steel slag, and slag dumping equipment, can solve the problems of wasting waste heat, dust, and large dust when the crane is dumped, so as to avoid environmental pollution and have a high degree of automation , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

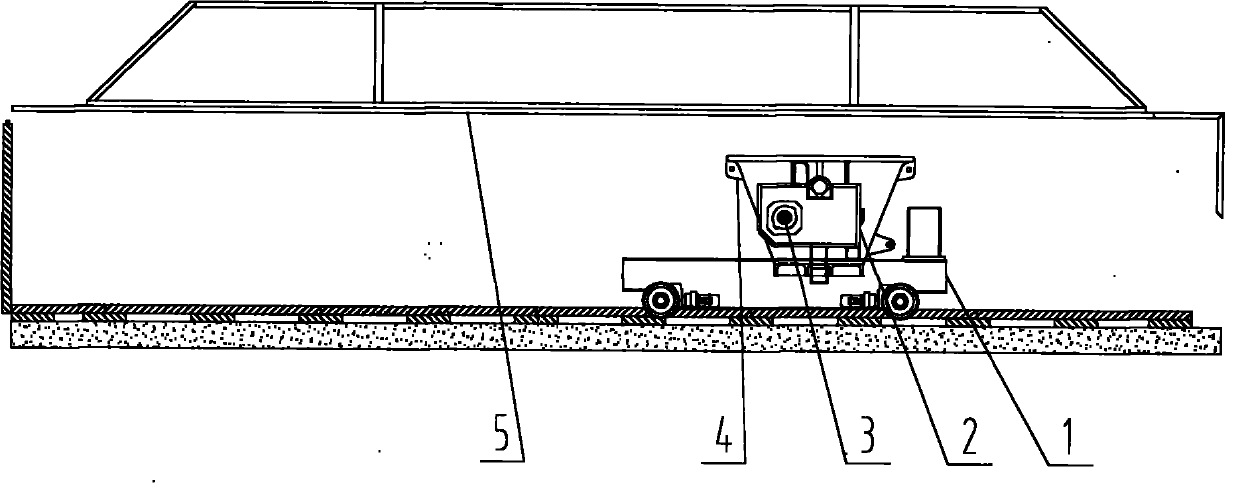

[0035] Such as figure 1 , figure 2 , image 3 It is a structural schematic diagram of the track-type slag tank tipping vehicle device of the present invention, including a trolley device 1 , a slag tank tipping device 2 , a slag tank locking device 3 , a slag tank 4 and a steel slag pretreatment chamber 5 .

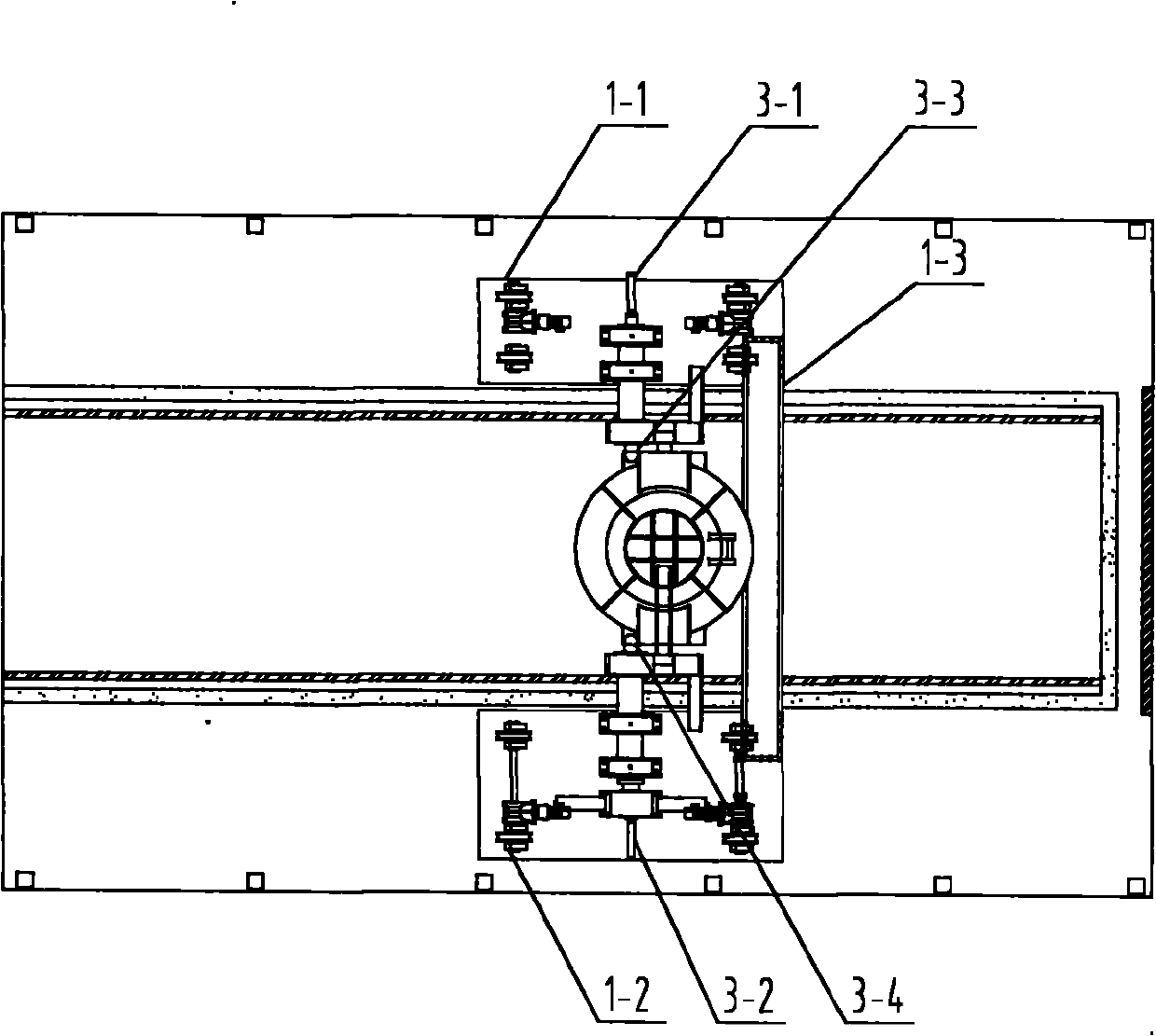

[0036] The trolley device 1 is a rail-type traveling trolley, comprising a left trolley 1-1, a right trolley 1-2 and a lintel 1-3. The trolley 1-1 on the left side and the trolley 1-2 on the right side are respectively located on the left and right sides of the steel slag pretreatment chamber 5, and the two are connected into one body through the lintel 1-3.

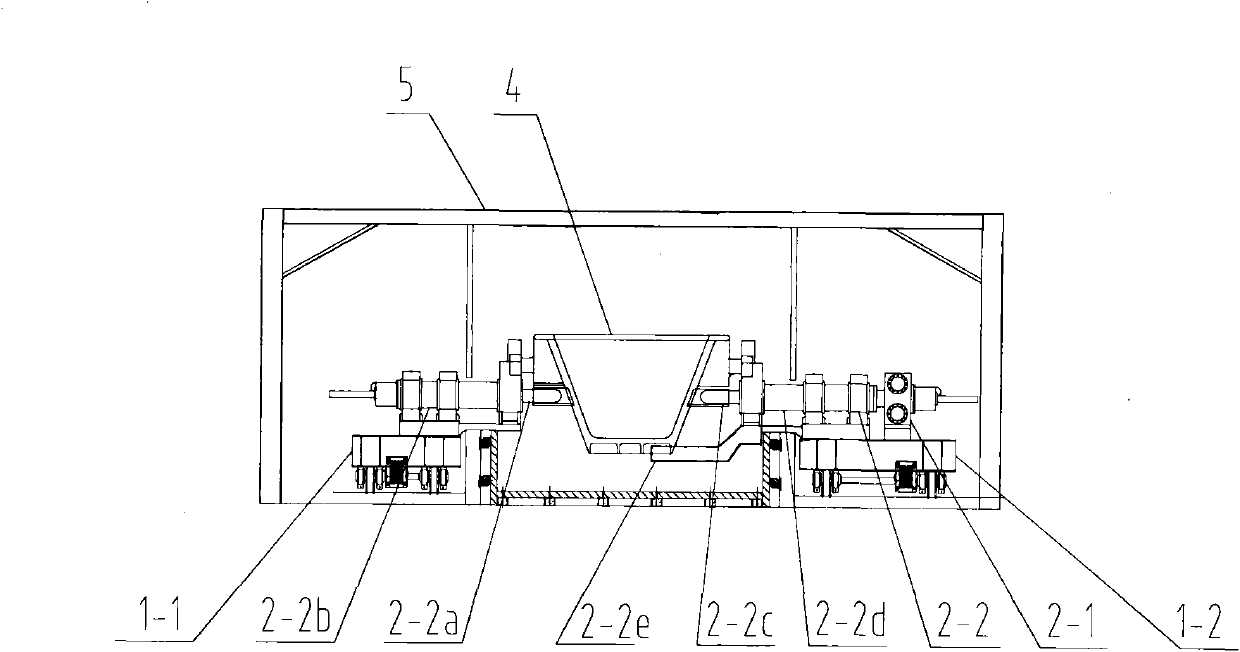

[0037] The slag pot tipping device 2 includes a tipping drive device 2-1 and a tipping device 2-2. Tilting driving device 2-1 can be hydraulic drive, also can be motor drive. The present embodiment adopts rack oil cylinder to drive.

[0038] The tipping device 2-2 includes a left slag tank support arm 2-2a, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com