Truss framed leg folding method of jack-up drilling platform

A drilling platform and self-elevating technology, applied to sheet pile walls, water conservancy projects, artificial islands, etc., can solve the problems of long-distance sea transportation such as high cost, impact, and long closing time of pile legs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

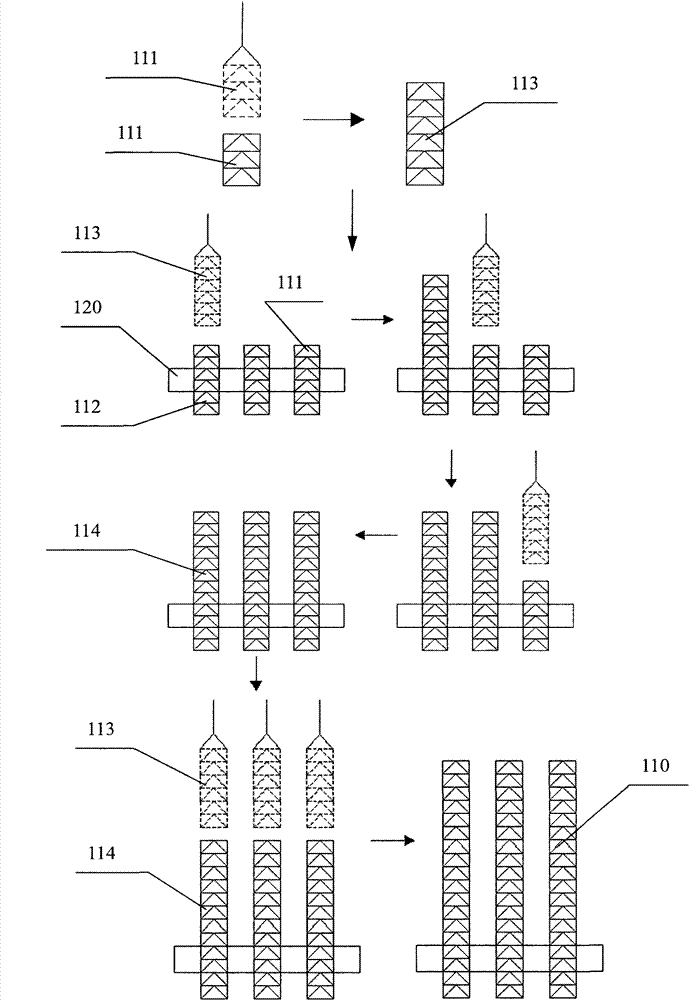

[0038] Such as figure 2 As shown, it is a schematic diagram of the implementation process of the method for closing the truss-type pile legs of the jack-up drilling platform according to the present invention. Among them, the basic steps are: setting of pile leg segment and base pile leg section—land closure—sea closure—making closure tooling and inspection line. Specific steps are as follows:

[0039] S1, setting a plurality of leg segments 111 and setting base leg segments 112 on the hull 120;

[0040] S2. Use a crane to close up a leg segment 111 on the base leg segment 112 on land;

[0041] S3, using a crane on land to close at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com