Caliper guide

A technology of caliper and catheter, which is applied in the field of guide and guard devices, can solve the problems of increasing the risk of scratching the caliper, unstable wire running, and increased wire friction, etc., to shorten the cycle of maintenance and correction, and to improve operation and maintenance. The effect of low cost and reliable guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

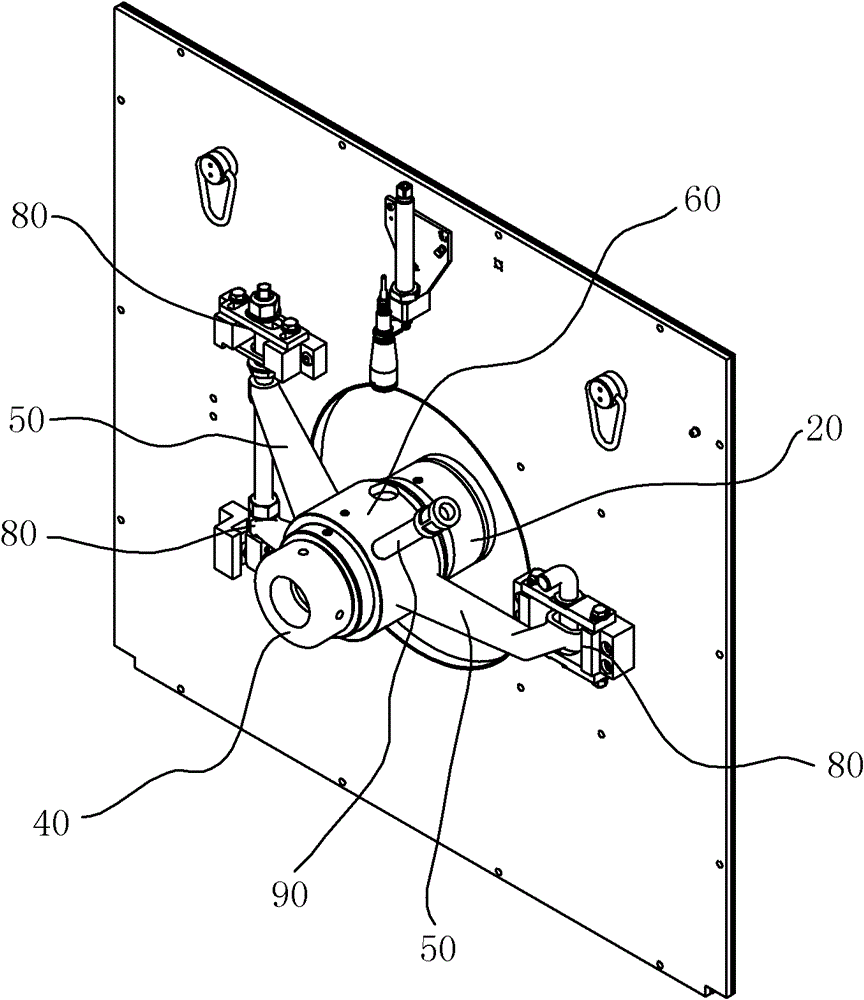

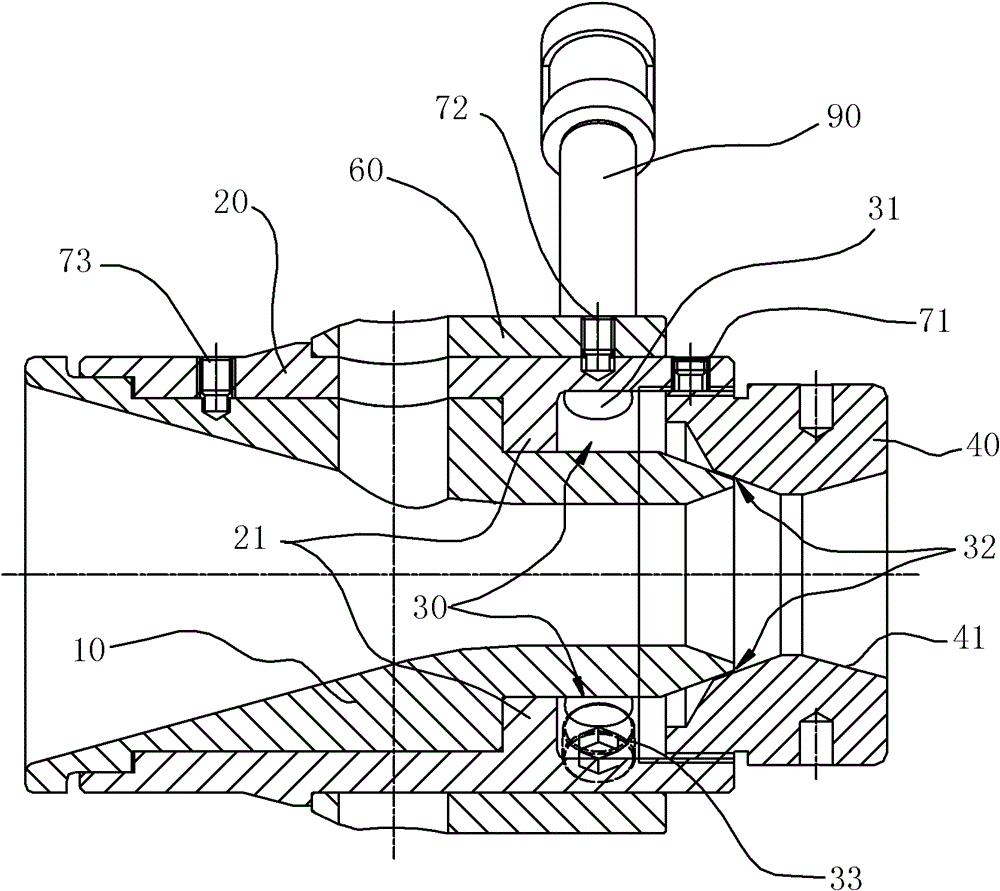

[0011] like figure 1 , 2 The shown caliper guide includes a conduit 10 for wires to pass through, and an airflow guiding mechanism is provided on the side of the conduit 10 close to the outlet of the material to guide the airflow and the material to travel in the same direction. That is to say, the air guide mechanism can guide the air in the caliper and the conduit 10 to flow in the same direction as the moving direction of the material.

[0012] Such an airflow guiding mechanism can be implemented in various ways, such as an air suction mechanism located at the outlet of the conduit 10 and the like.

[0013] Preferably, the airflow guiding mechanism is an air blowing mechanism, the exhaust channel 32 of the air blowing mechanism is oblique to the center of the guide tube 10 and along the traveling direction of the material, and the exhaust channels 32 are evenly distributed along the inner wall of the guide tube 10 .

[0014] That is to say that the present invention prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com