Diversion method for composite vacuum perfusion molding process

A composite material and vacuum infusion technology, which is applied in the field of composite material molding technology, can solve the problems of liquid resin loss, long molding time, and low production efficiency, and achieve the effects of improving compression resistance, shortening molding time, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Application example of vacuum infusion molding of large composite wind power blade with a length of 50m and a width of 5m.

[0021] The 50m wind turbine blade is divided into upper and lower shells. When forming, the upper and lower shells are respectively molded by vacuum infusion. After curing, the upper and lower shells are bonded together with an adhesive. The layering method of the upper and lower shells is exactly the same as the layering structure, any of which can be called a half shell.

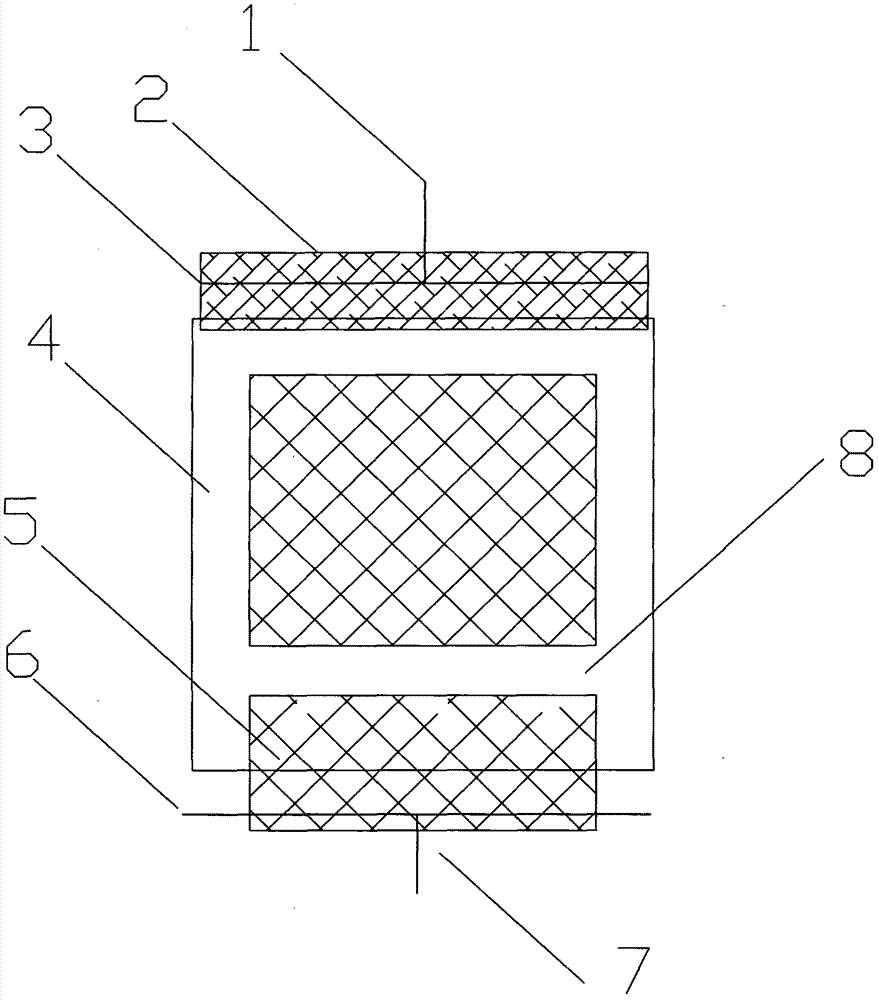

[0022] When the half shell is formed, three dry fiber layers are laid on the full surface of the half shell mold from 10m to 50m along the length direction, and the composite material prefabricated from unidirectional glass fiber is laid at 10m-50m along the length direction. The main beam is located at the center of the width direction of the forming mold. The honeycomb sandwich material with the same height as the main beam is laid on both sides of the main beam, and then 3 layer...

Embodiment 2

[0025] An application example of vacuum infusion molding of a large composite wind power blade with a length of 50m and a width of 5m.

[0026] The 50m wind turbine blade is divided into upper and lower shells. When forming, the upper and lower shells are respectively molded by vacuum infusion. After curing, the upper and lower shells are bonded together with an adhesive. The layering method of the upper and lower shells is exactly the same as the layering structure, any of which can be called a half shell.

[0027] When the half shell is formed, 100 dry fiber layers are laid on the entire surface of the lower shell from 0 m to 10 m in the length direction of the molding die.

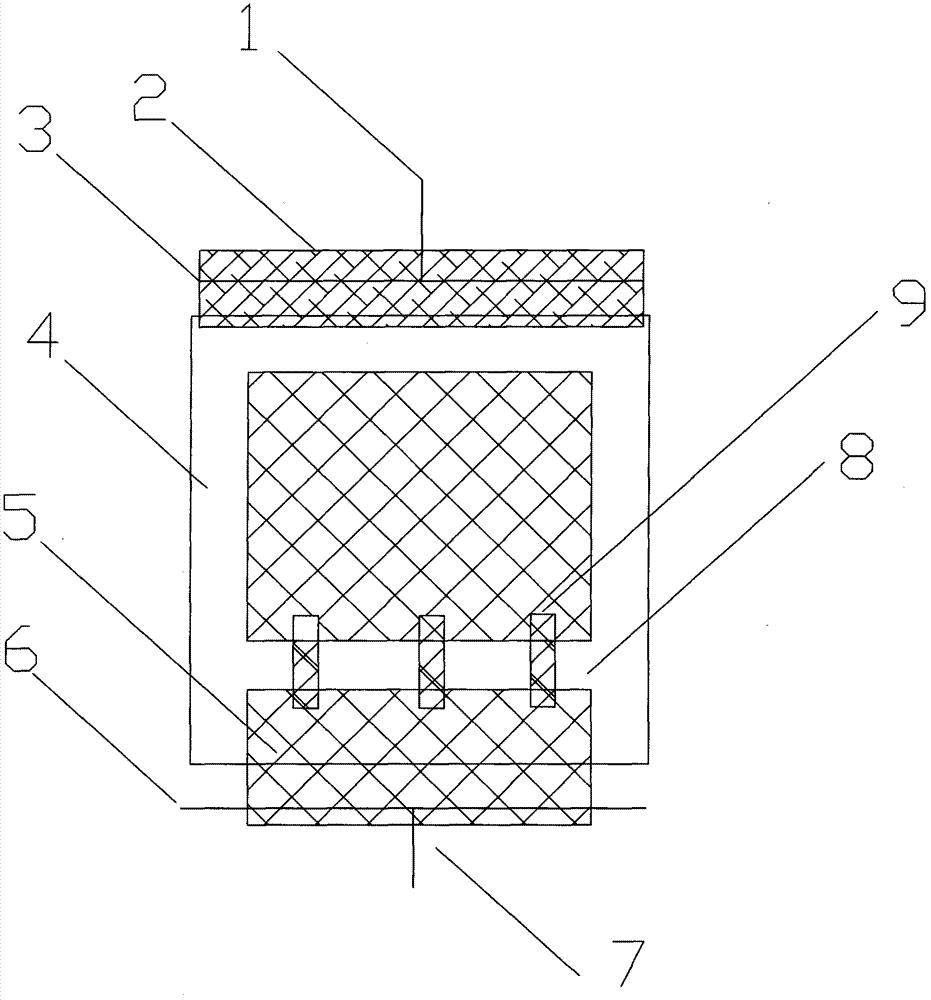

[0028] Then, two diversion media are laid on the upper surface of the dry paving layer along the width direction. This diversion medium is composed of a spatial net-like fabric with a certain thickness, and its function is to quickly disperse the liquid resin into these spatial net-like structures under vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com