System and method for online flaw detection of industrial X-ray machine

An X-ray machine, flaw detection technology, applied in the field of X-ray imaging, to achieve the effects of a wide range of applications, fast detection speed and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

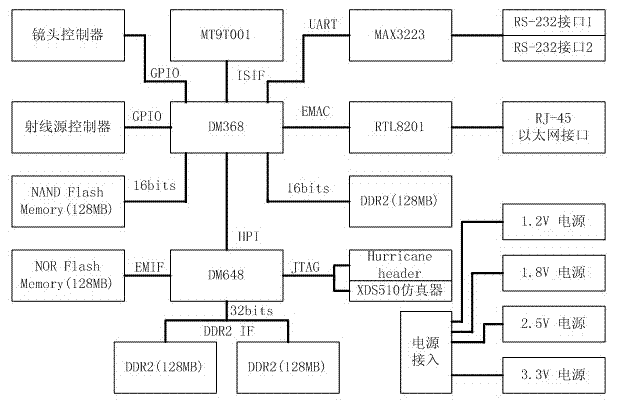

[0040] The industrial X-ray flaw detection equipment and method based on the bionic smart camera provided by the present invention will be further described below in conjunction with the accompanying drawings.

[0041] Such as figure 1 Shown is a schematic structural diagram of the industrial X-ray detection system in the present invention. The monitoring system is divided into two parts: the detection room and the monitoring room. The host in the monitoring room is connected to the smart camera through a 100M network card, and is connected with an audible and visual alarm device to activate the alarm when the work is abnormal. In addition to real-time display of the monitoring video of the inspection room, the software of the host computer in the monitoring room can also save defect images and information, perform parameter statistics on the analysis results, and remotely adjust the parameters of the ray source and lens. Since the host in the monitoring room has relatively ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap