Engraving device, cassette member and method for forming engraving pattern

A pattern and component technology, applied in the field of engraving devices, can solve problems such as inability to engrave and deterioration of engraving quality, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

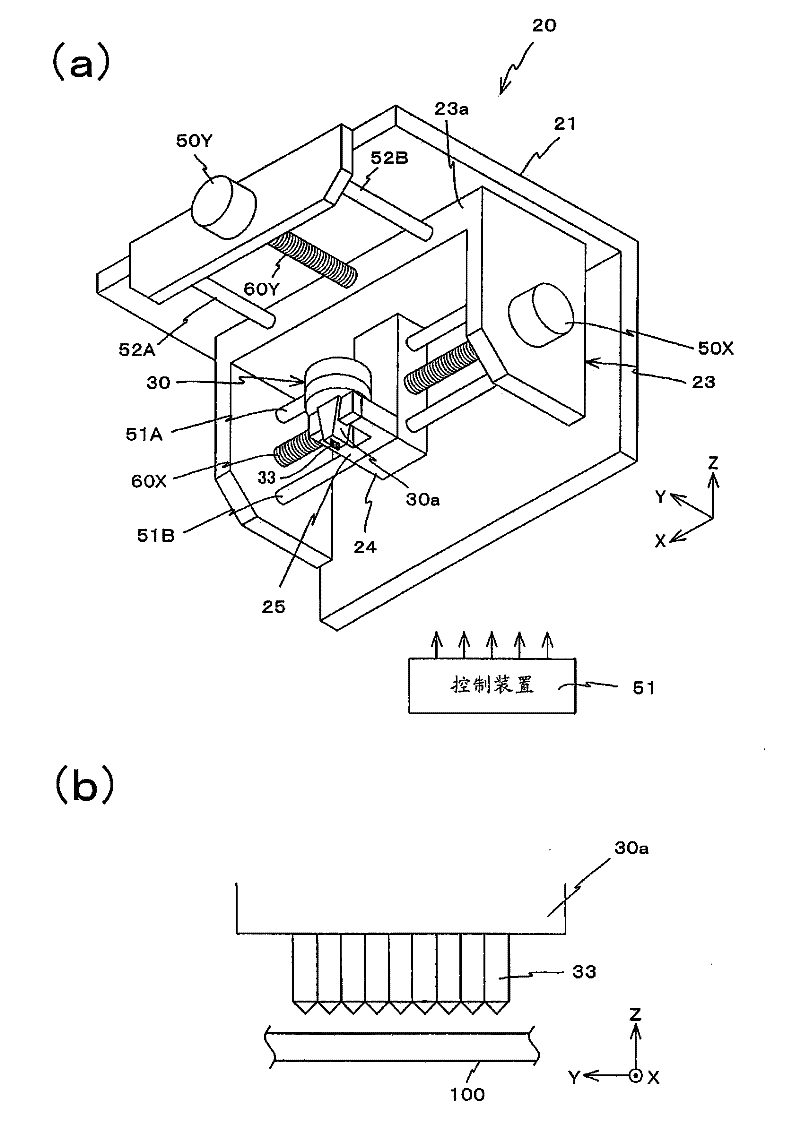

[0051] Hereinafter, a marking device according to an embodiment of the present invention will be described with reference to the drawings.

[0052] The marking device according to this embodiment forms a two-dimensional code, characters, and the like composed of a plurality of dots on the surface of an object to be marked.

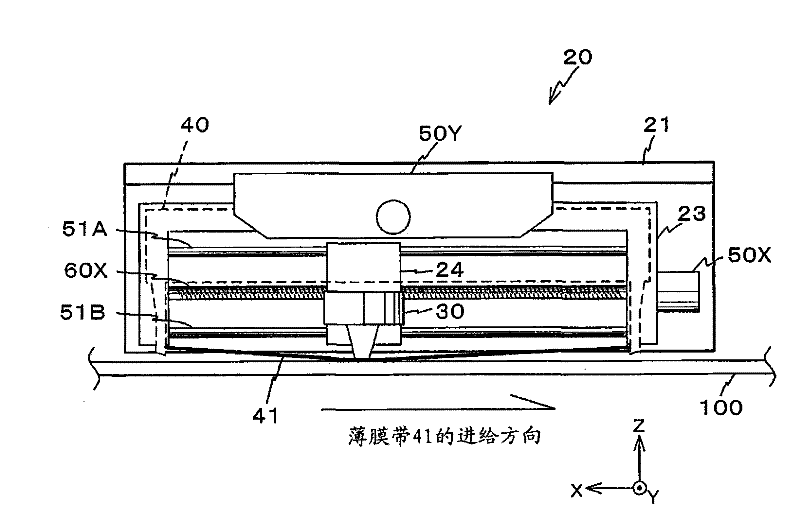

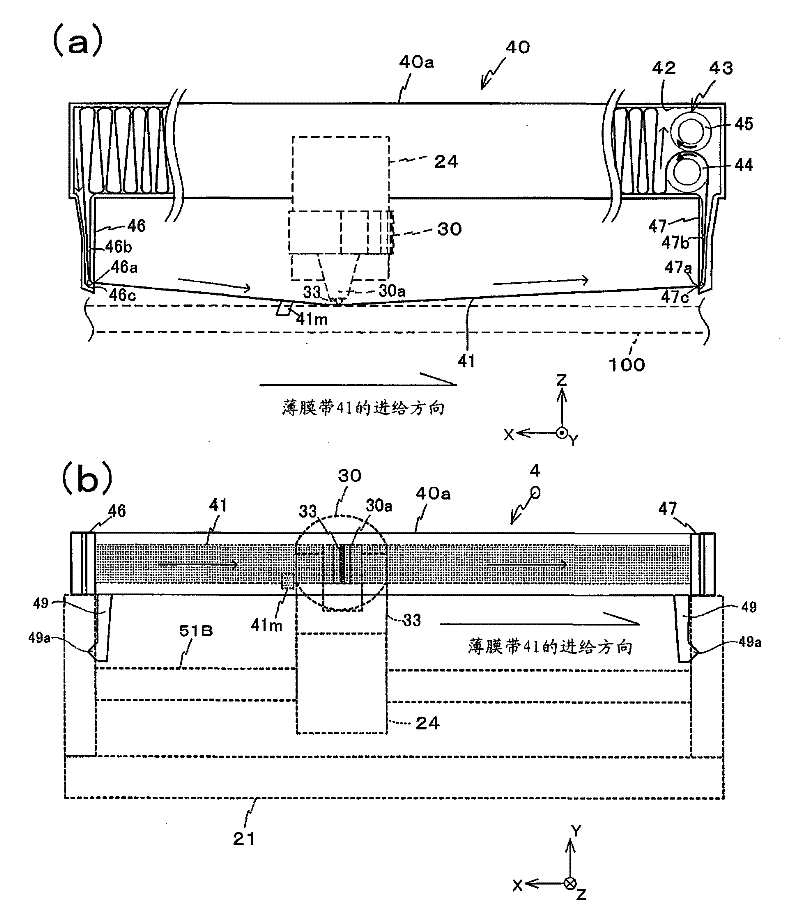

[0053] The marking device 20 according to this embodiment is as figure 1 (a) includes as shown: Y moving body 23; X moving body 24 supported on Y moving body 23; U-shaped bracket 25 fixed on X moving body 24; Striking head 30. In addition, the marking device 20 further includes a control device 51 that controls the overall operation.

[0054] The engraving device 20 moves the engraving head 30 in the X-axis direction and the Y-axis direction by means of the Y moving body 23 and the X moving body 24. Engraving multiple points to form a variety of engraving patterns.

[0055] The Y moving body 23 is composed of a member having a U-shaped cross section, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com