Composite sensor and composite-sensor-based aircraft engine gas circuit fault detection and diagnosis method

A composite sensor, sensor technology, applied in instruments, measuring devices, scientific instruments, etc., to achieve the effect of promoting the improvement of aviation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The composite sensor of the present invention and the method for diagnosing the gas circuit fault of an aeroengine based on the sensor are described in conjunction with the accompanying drawings and embodiments.

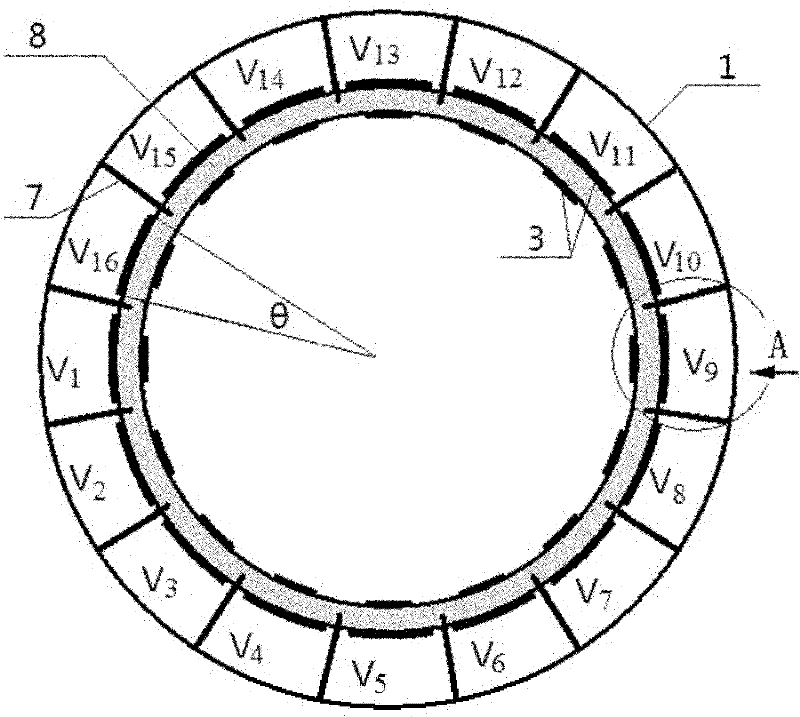

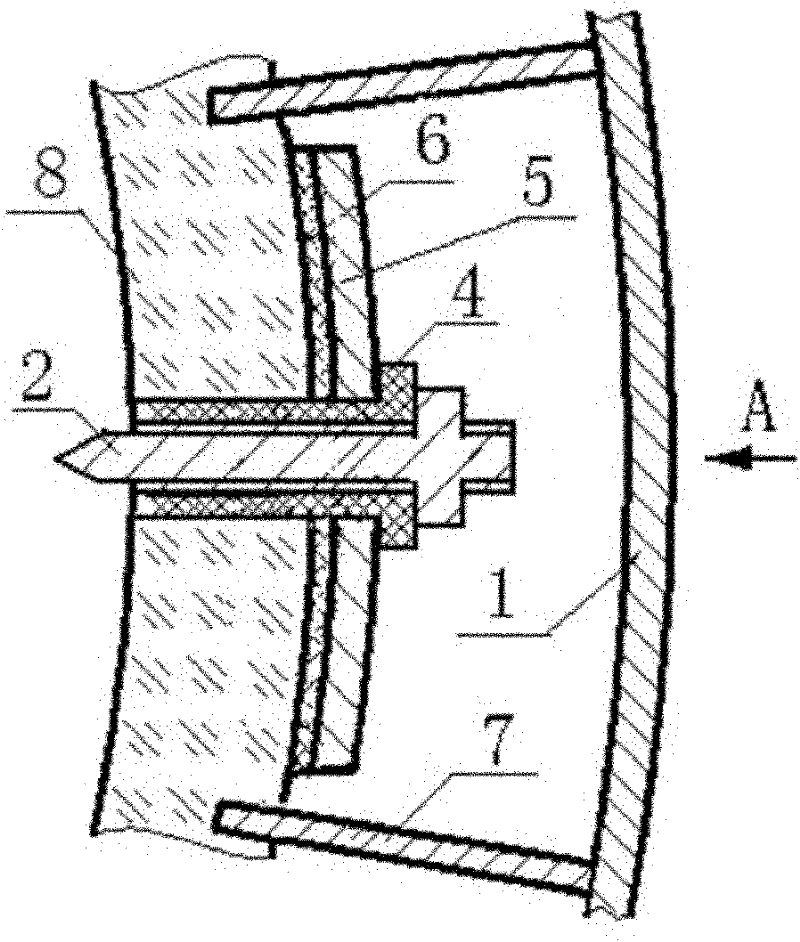

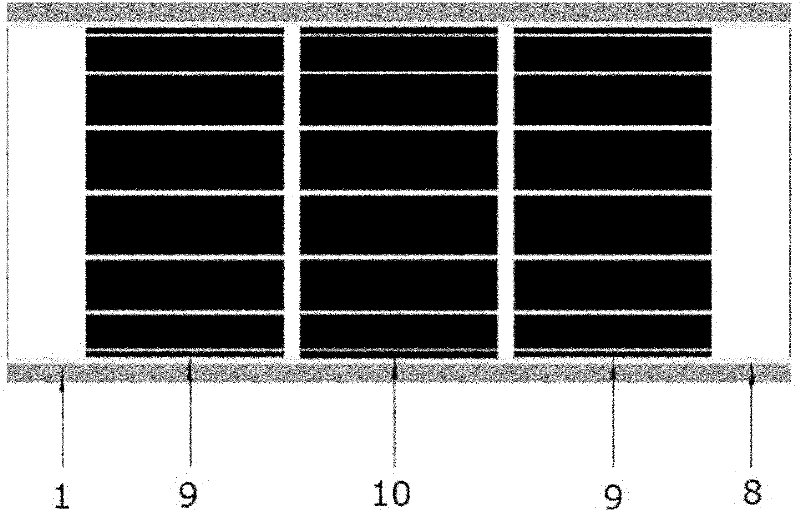

[0026] The composite sensor structure of the present invention is that the radial cross-sectional structure of the composite sensor is three layers, an outer layer, an inner layer, and an intermediate layer, and the outer layer is a shielding electrode layer, and this layer includes a metal shielding cover 1, which plays a shielding role. The radial electrode 7, which plays the role of structurally fixed and isolated detection electrode, is connected with one end of a plurality of radial electrodes 7 at equal intervals on the inner circumference of the metal shield 1; the inner layer is a metal pipe 8, and a plurality of radial electrodes The other end of 7 is connected to the metal pipe 8; the middle layer is the detection electrode layer, which includes a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com