Single-chart self-calibration method of catadioptric omnibearing camera mirror plane pose

A technology of mirror surface and refraction, which is used in image analysis, image data processing, instruments, etc., and can solve the problem of difficulty in ensuring installation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

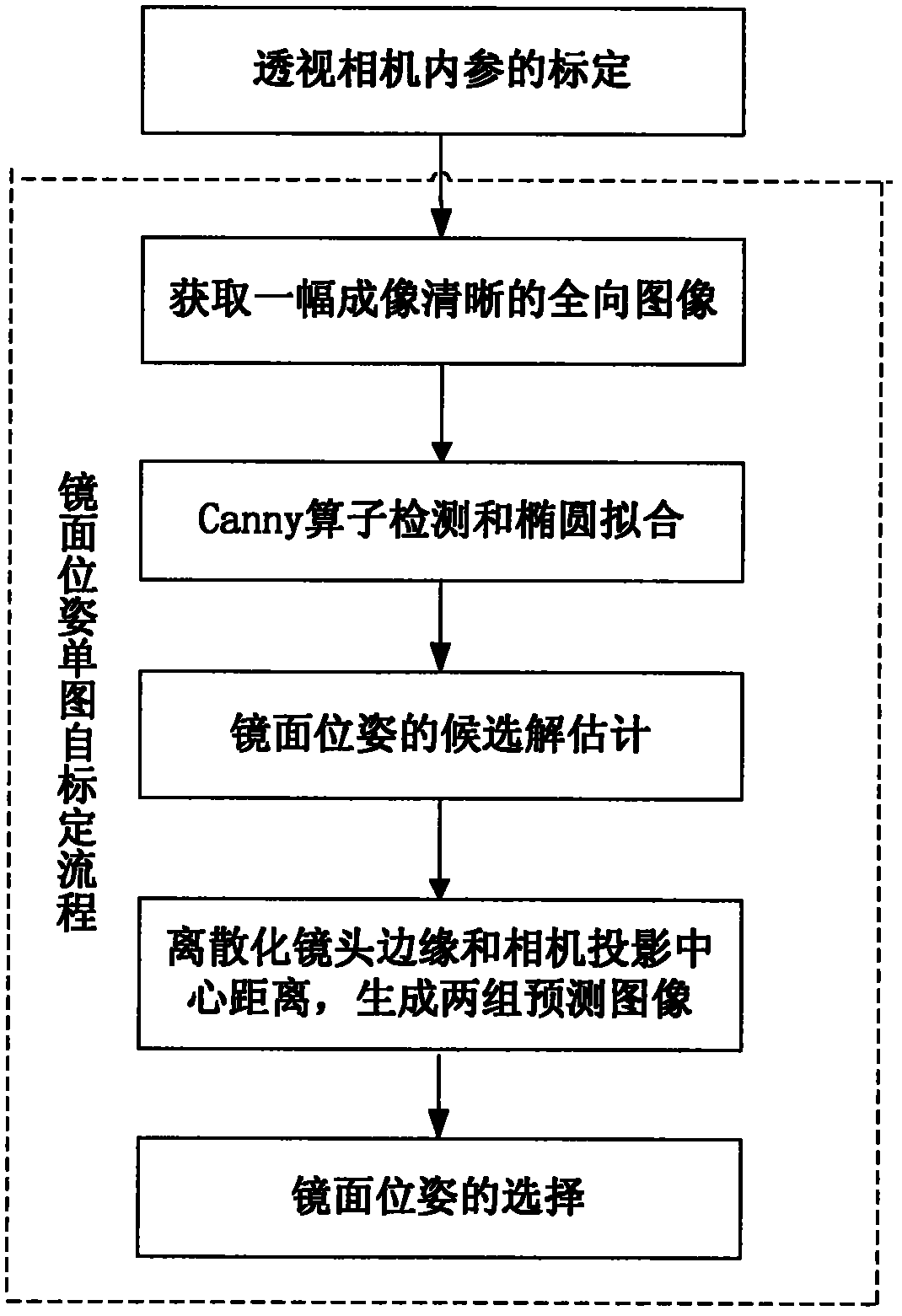

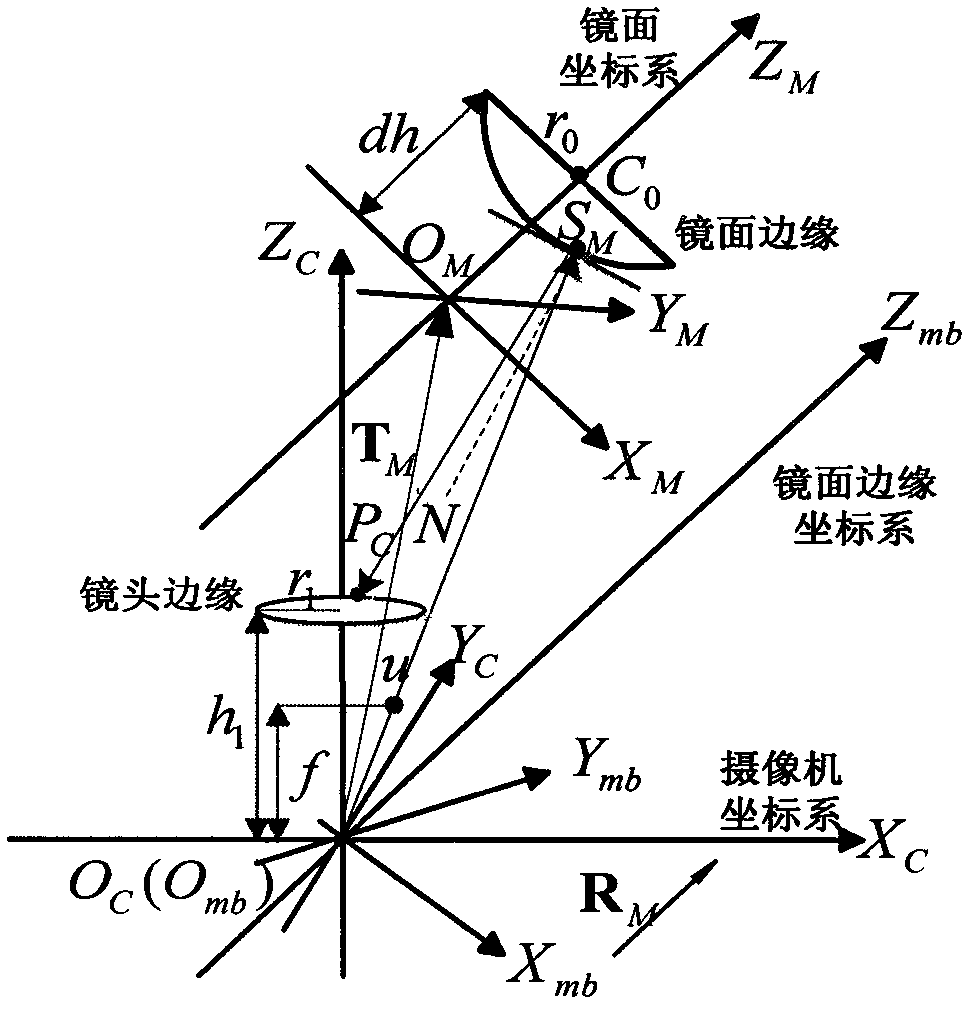

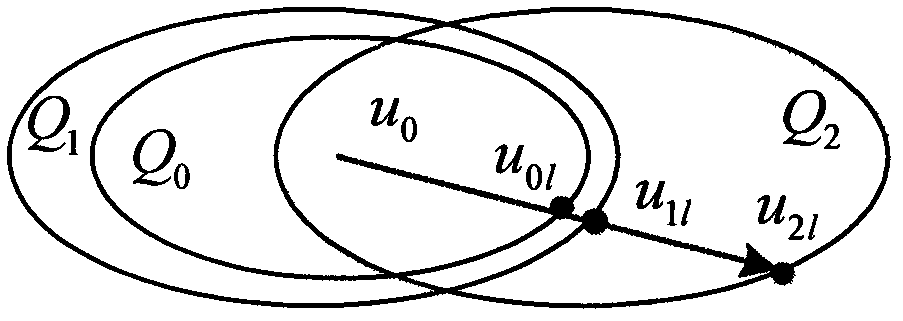

[0048] The catadioptric omnidirectional camera system consists of a perspective camera and a reflective mirror. figure 1 The technical flow of the catadioptric omnidirectional camera calibration method is given. The process includes two parts: the internal reference calibration of the perspective camera and the single-image self-calibration of the mirror pose. The single-image self-calibration of the mirror pose includes the following five parts: ① Obtain a clear omnidirectional image; ② Canny operator detection and ellipse fitting: use the Canny operator to detect the edge of the mirror surface and the camera lens in the image respectively For the imaging boundary of the edge, use the point sets composed of these two groups of elliptical imaging boundary pixels to fit the equations of two ellipses respectively; the two elliptic coefficients a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com