Method and system of operating a fuel vapor recovering system and its engine system

A fuel vapor and recovery system technology, applied in combustion engines, internal combustion piston engines, charging systems, etc., can solve the problems of increasing component costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

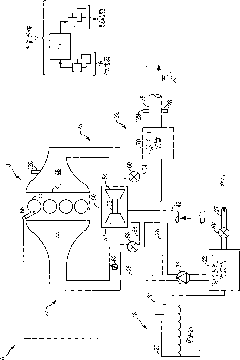

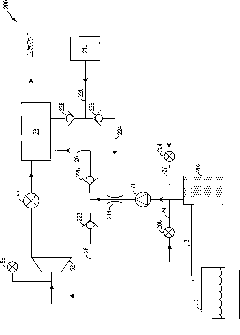

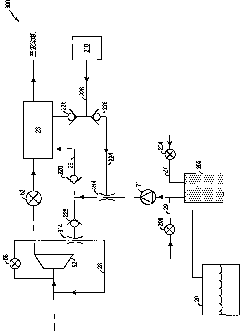

[0014] The following description relates to systems and methods for generating a vacuum generated by an ejector using a purge pump during fuel vapor canister purge and non-purge conditions. Such as Figure 1-3 As shown in , the extraction pump can be connected to the fuel vapor canister of the fuel vapor recovery system to pump the extraction flow through the fuel vapor canister to the intake manifold of the pressurized engine. One or more ejectors may be connected to the pump and may pump evacuated air through the canister, through the ejectors to the engine intake. As such, pumping the evacuation flow through the ejector may create a negative pressure at the ejector, which may be applied by the ejector to a vacuum actuator (eg, a power brake and / or a wastegate actuator). The controller can be configured to perform as Figure 4 The procedure shown in to run the extraction pump to generate vacuum at the ejector when engine boost is present. Vacuum actuation may be performed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com