Intelligent positioning and calibration method

A calibration method, a technology of intelligent positioning, applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve problems such as low efficiency and lack of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following embodiments are further provided in conjunction with the contents of the present invention:

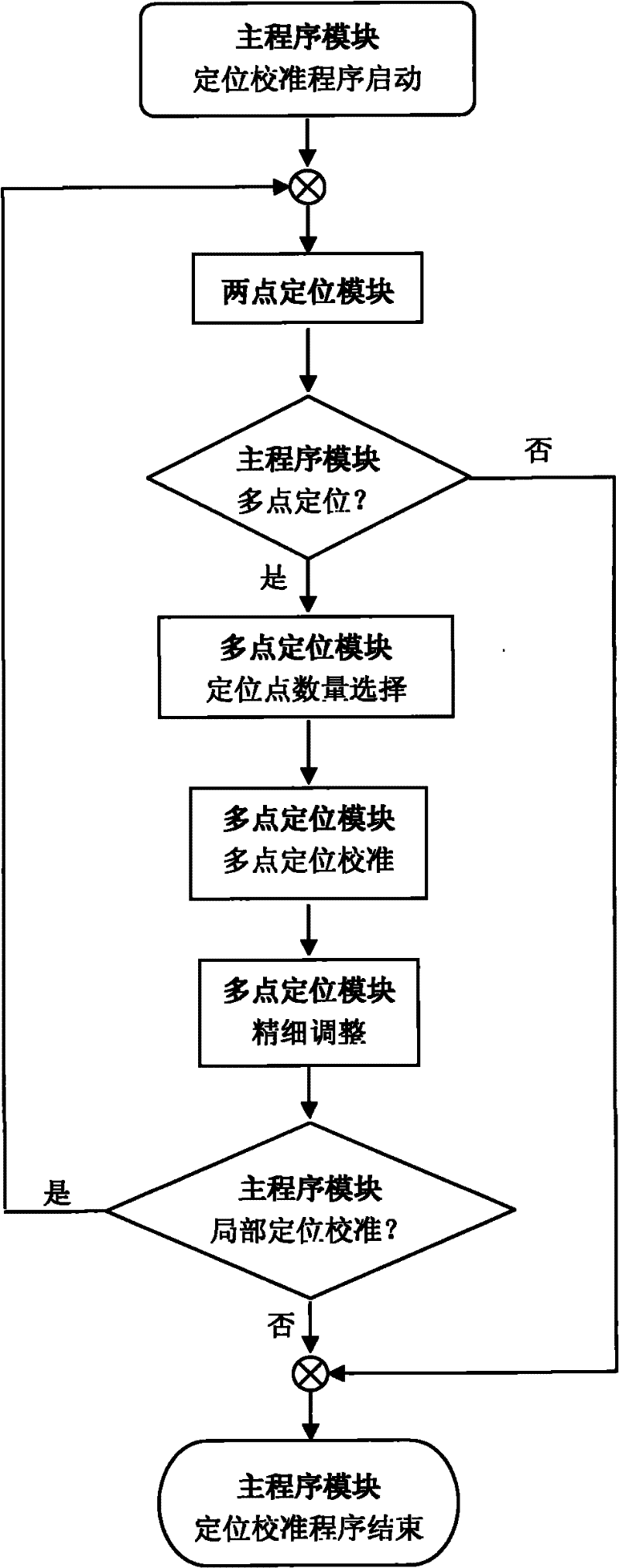

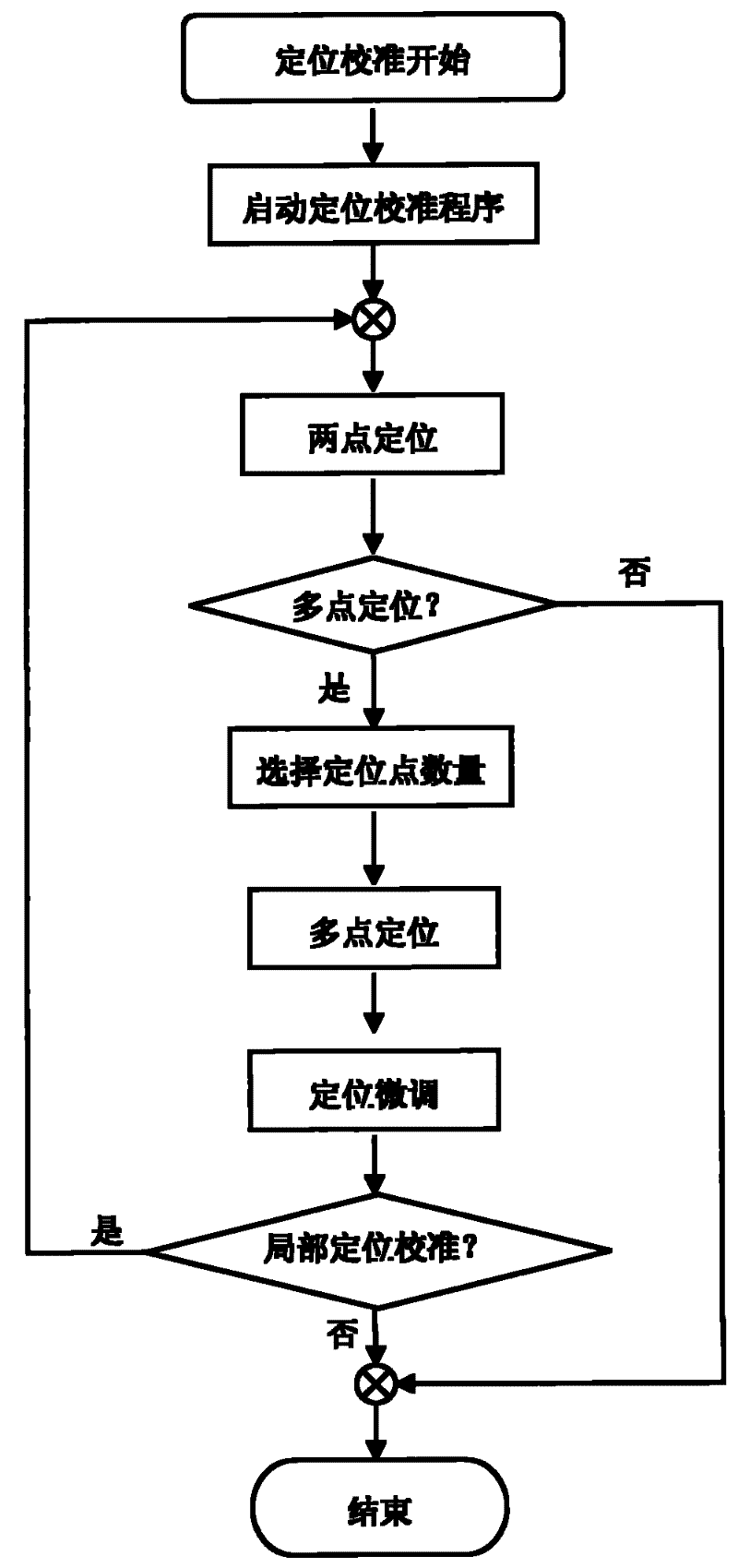

[0013] see figure 1 , a prototype system is developed based on the method of the present invention, the system includes: a main program module 100 , a two-point positioning module 200 and a multi-point positioning module 300 . The working process of the system is as follows: the first step, start the main program module 100 positioning calibration program; the second step, call the two-point positioning module 200, select two points on the upper left and lower right diagonal corners of the display area that needs positioning calibration to perform positioning , after the positioning is finished, exit the two-point positioning module 200 and enter the main program module 100; the third step, the main program module 100 prompts the user whether to perform further multi-point positioning calibration, if the user chooses to end, then exit the main program, if If the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com