Improved micro switch fixing structure for electric push rod

A technology of micro switches and electric push rods, applied in the direction of electric switches, circuits, electrical components, etc., can solve the problems of small installation space, offset of travel switch position, affecting the response speed of travel switches, etc., and achieve the effect of fast and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

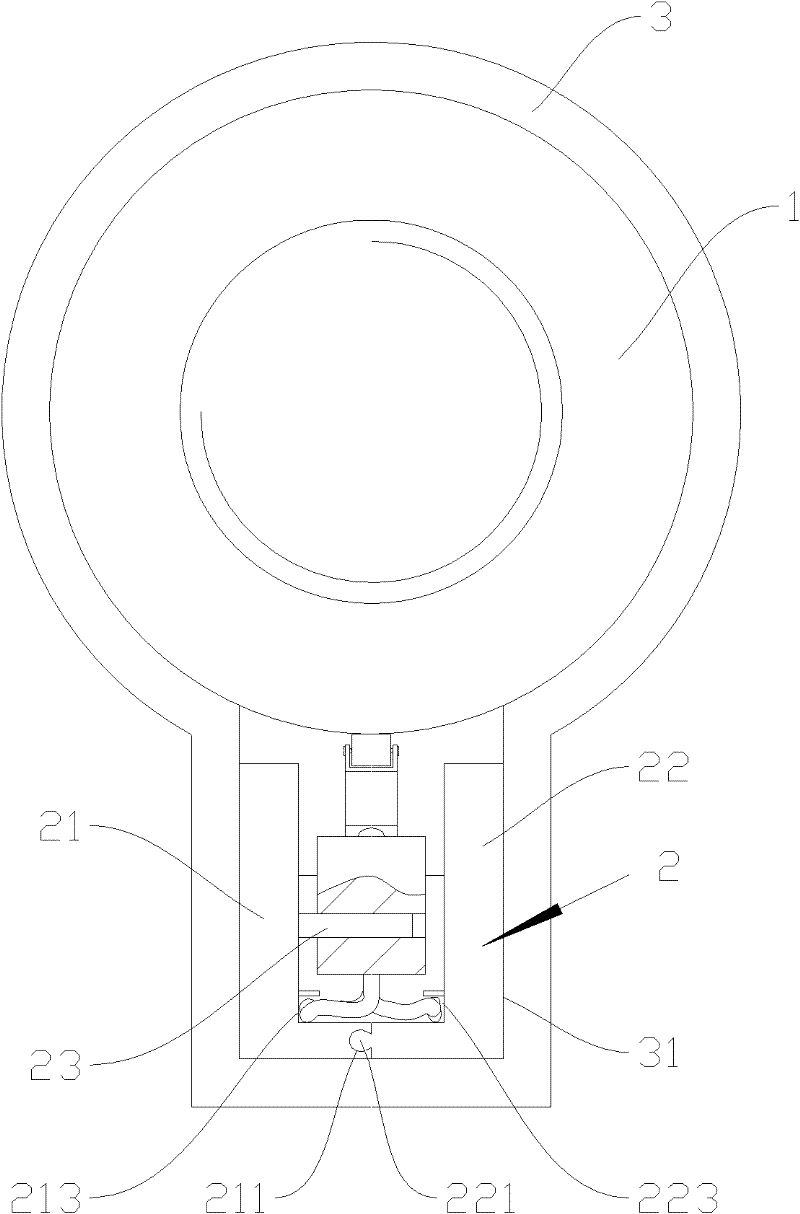

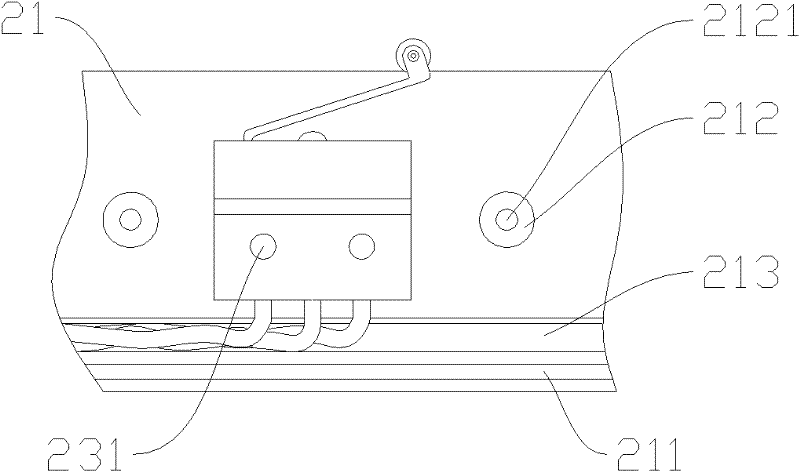

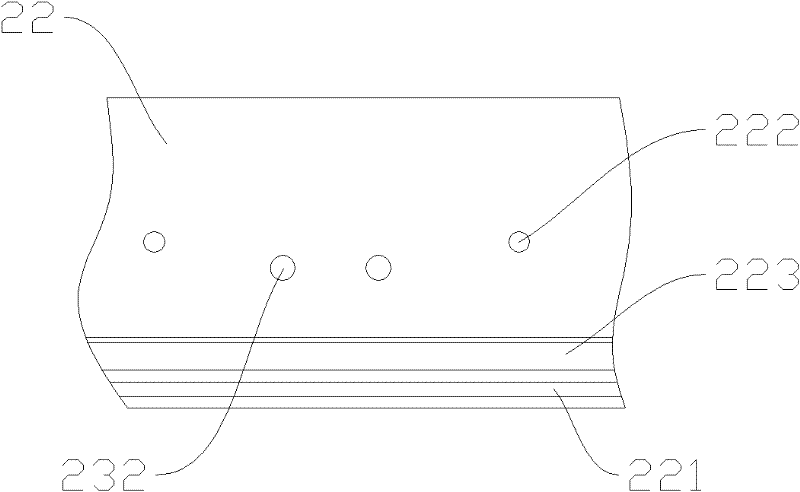

[0018] Such as Figures 1 to 3 Shown is a structural schematic diagram of an embodiment of the present invention, an improved micro switch fixing structure for an electric push rod, including a fixed plate assembly 2 arranged under the push rod 1 for fixing the micro switch, and the fixed plate assembly includes The fixed plate I21 and the fixed plate II22 that are interlocked with each other, the bottom of the fixed plate I is provided with a card slot 211, and the bottom of the fixed plate II is provided with a card bar 221 corresponding to the card slot; vertical on the inner wall of the fixed plate I There is an insertion rod 23 corresponding to the installation hole on the micro switch, and the length of the insertion rod is not greater than the width of the micro switch; between the fixed plate I and the fixed plate II, there is also a clamp to prevent the fixed plate I and the fixed plate II from The protection structure of the tight micro switch is provided with a push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com