Dust collector

A technology for vacuum cleaners and containers, which is applied in the directions of vacuum cleaners, cleaning equipment, household appliances, etc., can solve the problems of the large-scale float and the weight of the vacuum cleaner itself, and achieve the effect of eliminating unstable movements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

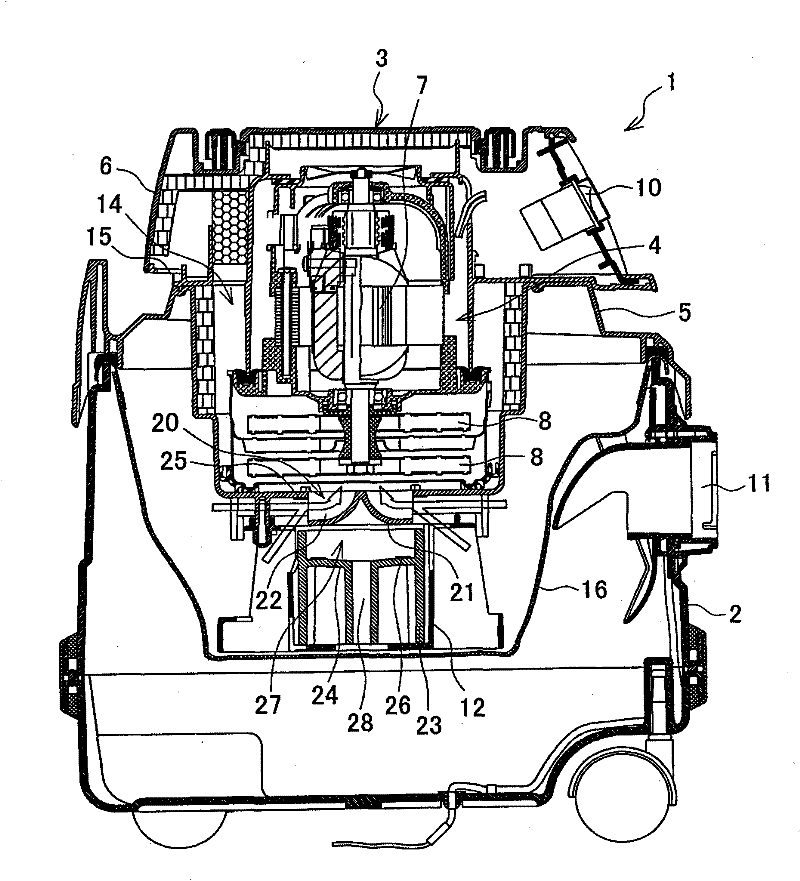

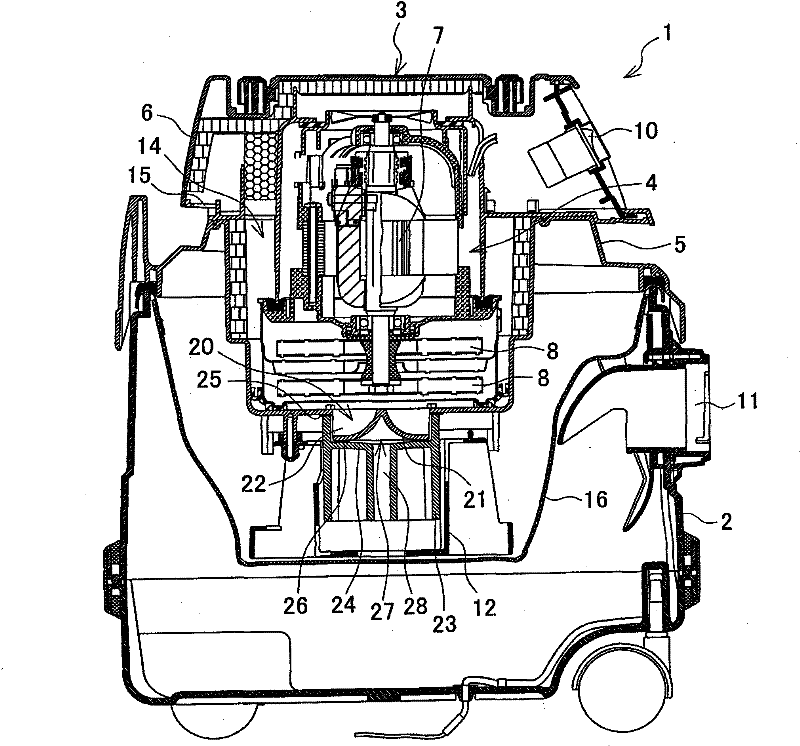

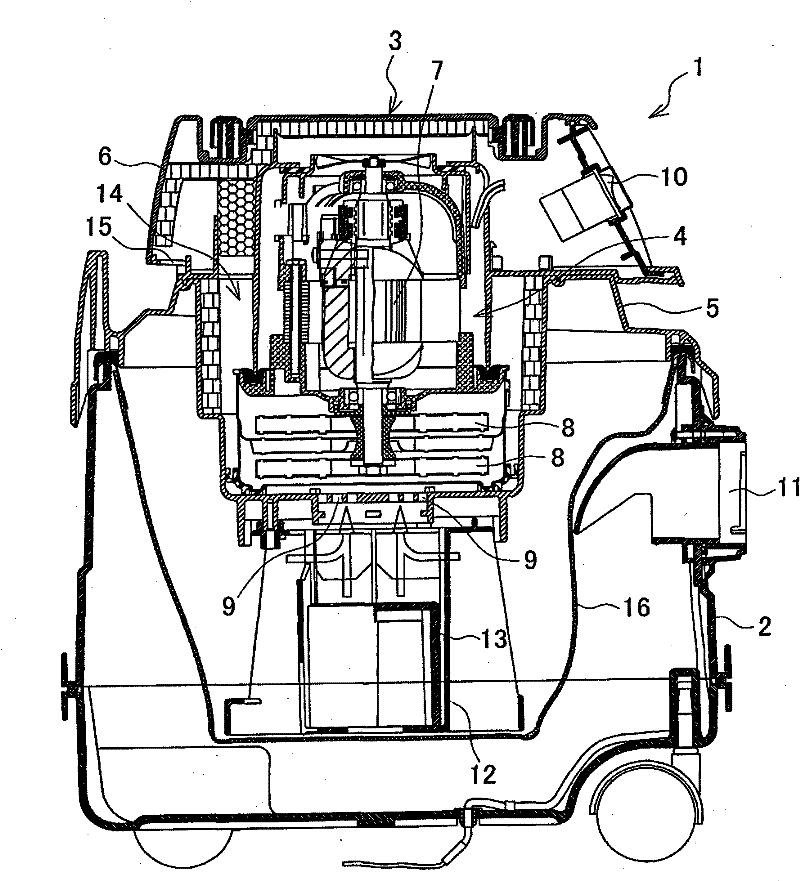

[0014] figure 1 A longitudinal sectional view showing an example of a vacuum cleaner, for which the basic structure such as a container and a body is the same as image 3 The shown conventional vacuum cleaner is the same, and the same components are given the same reference numerals, and repeated explanations are omitted, and the different components will be mainly described.

[0015] First of all, in this vacuum cleaner 1, the first difference is that the suction port 20 formed on the lower side of the suction unit 4 does not open downward, but is more open than the bottomed cylindrical container cover 5 that is the outer shell of the suction unit 4 . Also protrudes downwards and opens laterally. Specifically, the conical lower plate 21 , which is circular in plan view, is connected to the container cover 5 via the partition plate 22 , so that the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com