Safety joint

A technology of safety joints and pipe joints, which is applied in the direction of pipes/pipe joints/pipe fittings, hose connection devices, container structure installation devices, etc., and can solve problems such as danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

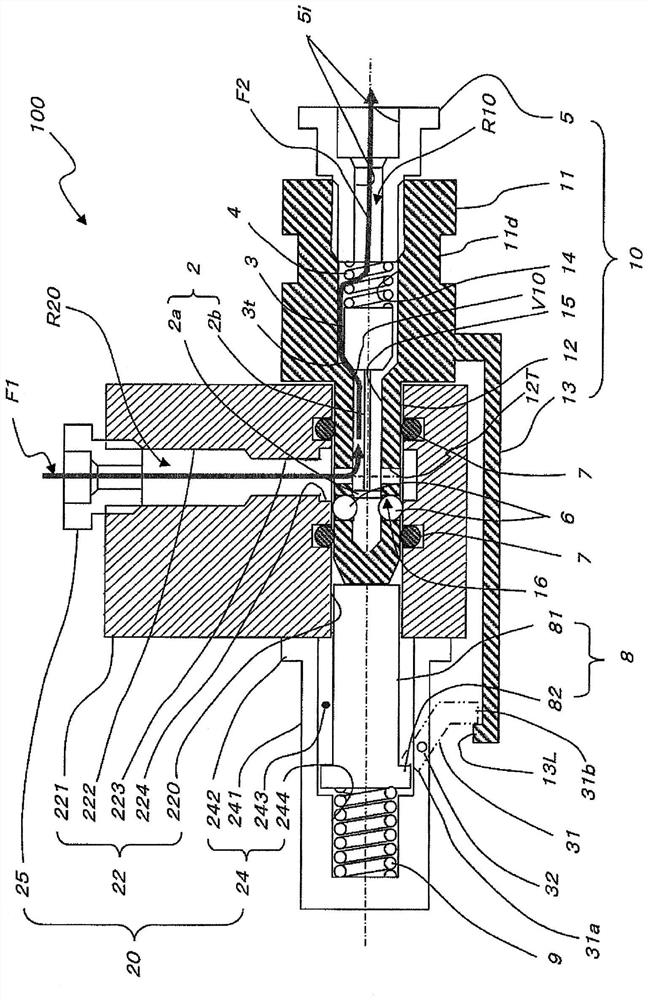

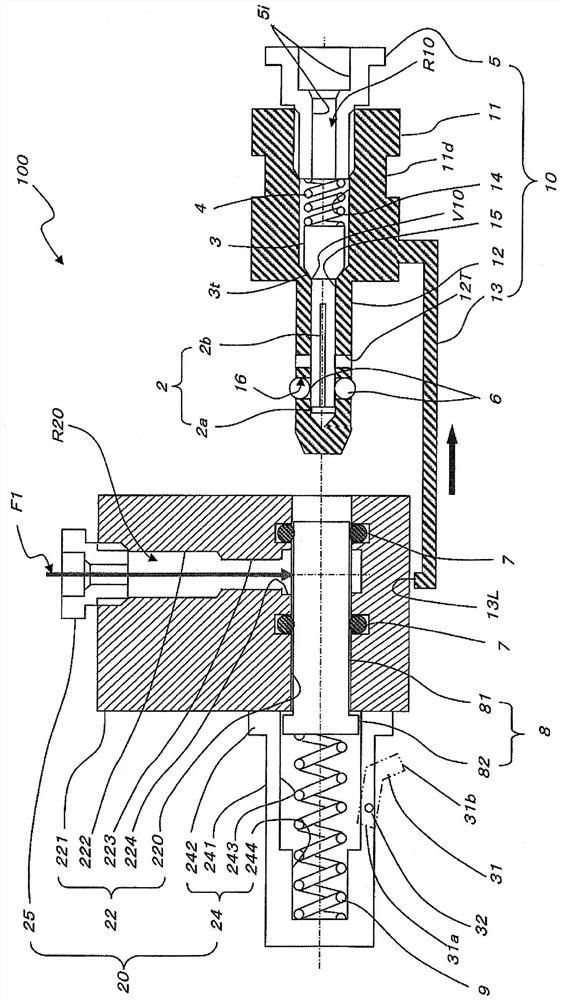

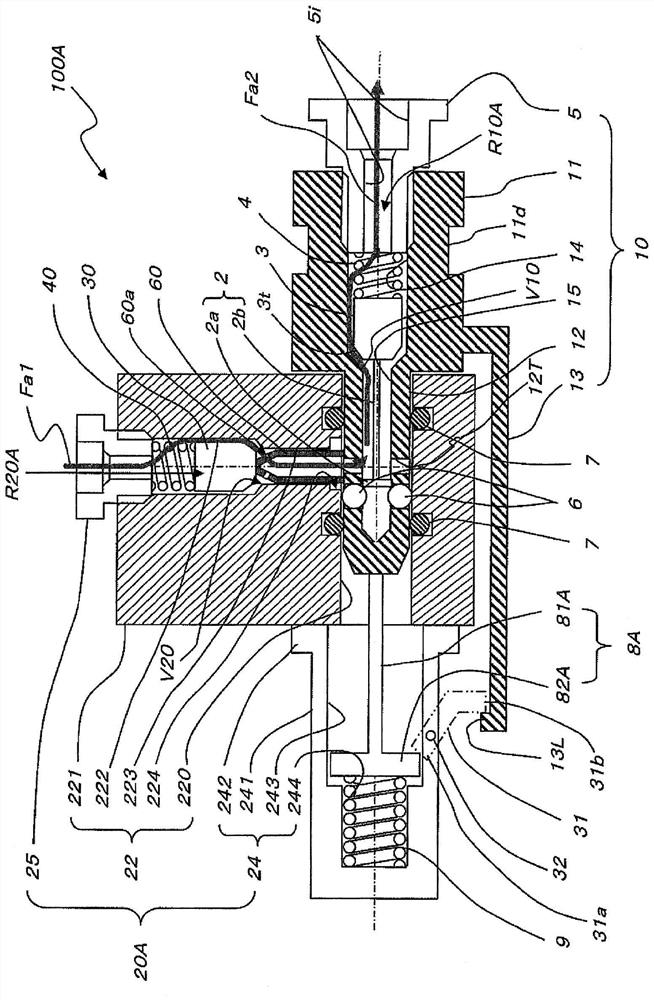

[0050] Hereinafter, embodiments of the present invention will be described with reference to the drawings. First, refer to figure 1 , figure 2 The first embodiment will be described. exist figure 1 Among them, the safety joint of the first embodiment, which is indicated by the reference numeral 100 as a whole, includes a nozzle-side member (plug) 10 and a filling device-side member (socket) 20 .

[0051] The plug 10 has a plug body 11 and a plug protrusion 12 integrally formed with the plug body 11 . The plug body 11 has, for example, a cylindrical shape, and a narrowed portion 11d having a small diameter is formed in the substantially center thereof. The plug protruding portion 12 is formed, for example, in a cylindrical shape with a diameter smaller than that of the plug body 11, and is opposite to the side away from the plug body 11 ( figure 1 , figure 2 The center is the left side) the end is chamfered.

[0052] A second flow path 14 is formed in the plug body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com