Sealing device for gas tank

A technology for sealing devices and gas cabinets, applied in the field of sealing, which can solve the problems of high possibility of tipping, shortened life, and increased wear of sealing rubber strips, so as to improve operating safety and prevent tipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

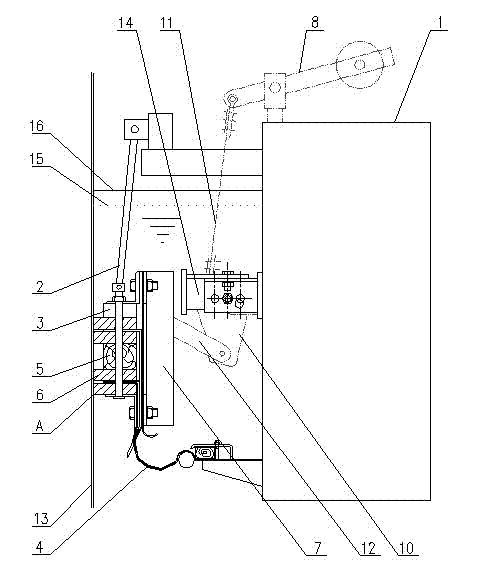

[0013] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0014] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure, the gas cabinet sealing device of the present invention includes two groups of sealing assemblies arranged up and down along the axis of the gas cabinet, the rubber suspension mechanism 2 fixed on the piston box beam 1 and the rubber suspension mechanism 2. Compression mechanism; the sealing assembly includes a pressing plate 3, a sealing canvas 4, a sealing rubber strip 6 separated by a wooden clamp 5, and a rubber clamping mechanism 7, which are connected as a whole by a screw, and one end of the sealing canvas 4 is installed on the Between the sealing rubber strips 6, the other end is installed on the piston box beam 1; the sealing assembly is suspended on the piston box beam 1 through the rubber suspension mechanism 2; 1 The connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com