Production device for modified multi-winding-machine bed mesh spring

A production device and improved technology, which is applied in the field of improved multi-winding machine tool net spring production device, can solve the problems that cannot meet the requirements of high-efficiency development of bed net springs, limit the versatility of bed nets, and low spring efficiency, etc. Achieve the effects of improving spring supply efficiency, improving sleep comfort, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

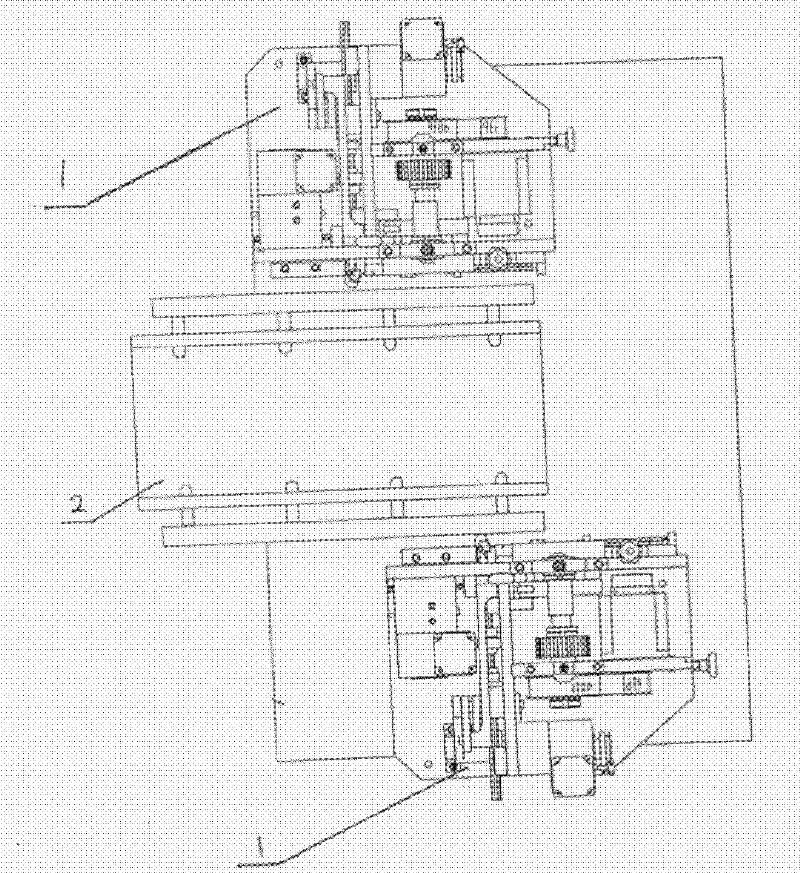

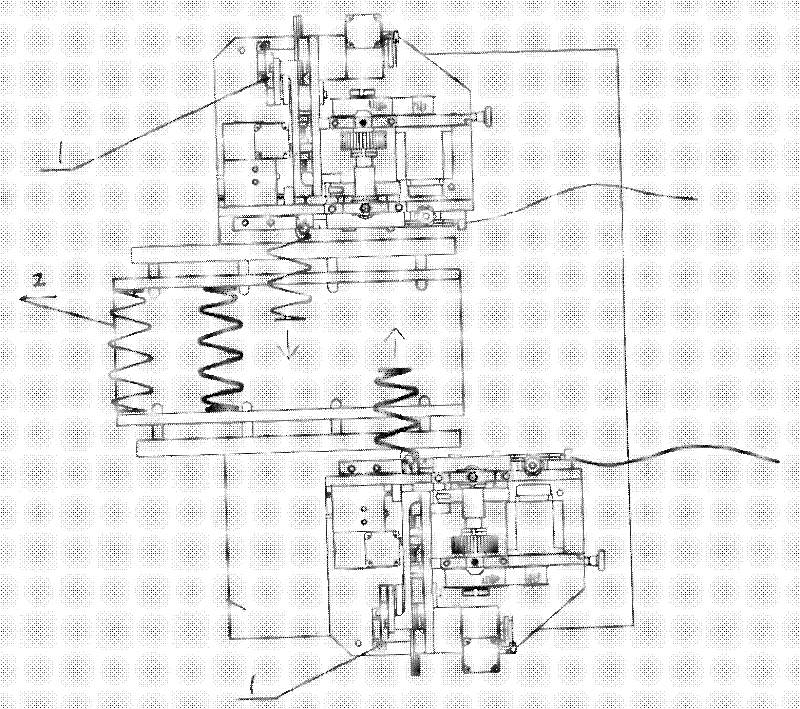

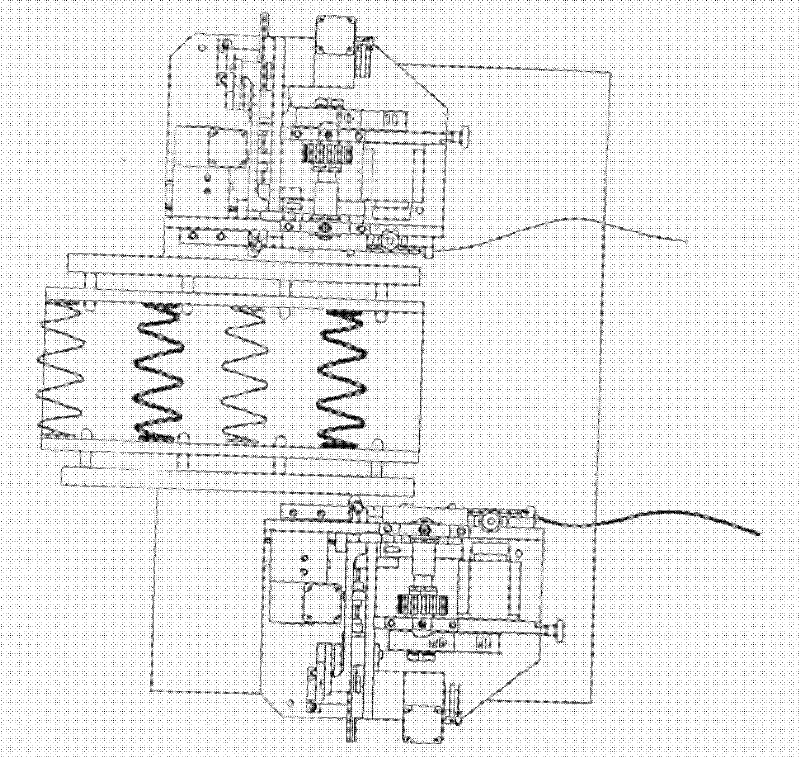

[0017] refer to Figure 1 to Figure 7 , Figure 16 , this example includes two commonly used spring winding machines 1, and a pocket spring packaging machine is arranged in the middle (the applicant's ZL200520119964.4 patented technology can be cited). The two spring winding machines 1 can feed steel wire materials with different diameters, so as to provide thick and thin springs for the bag spring packaging machine. The working process is as follows: Figure 2 to Figure 7 shown. Made of pocket spring bed mesh such as Figure 16 As shown, the steel wire spring 3 with a thicker diameter is used as the hard sleeping area of the bed net, and the steel wire spring 4 with a thinner diameter is used as the soft sleeping area of the bed net, so that the sleeping comfort can be improved according to the curve of the human body.

Embodiment 2

[0019] refer to Figure 8 ~ Figure 15 , Figure 17 , This example includes two commonly used spring winding machines 1. There is a general-purpose string-type spring bed net production machine in the middle. Two spring winding machines 1 can feed steel wire materials of different diameters, so as to provide thick and thin springs for the series net type spring bed net production machine (the spring forming process is the prior art), and its working process is as follows Figure 10 ~ Figure 15 shown. Made of string net type spring bed net such as Figure 17 As shown, the steel wire spring 3 with a thicker diameter is used as the hard sleeping area of the bed net, and the steel wire spring 4 with a thinner diameter is used as the soft sleeping area of the bed net, so that the sleeping comfort can be improved according to the curve of the human body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com