Freight transport cableway hanger for transmission lines

A technology for freight cableways and power transmission lines, which is applied in the direction of cable railways, railway vehicles, transportation and packaging, etc. It can solve problems such as construction accidents, rope jumping out, hangers that cannot swing slightly with the ropes, etc., and achieve the effect of reducing construction accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

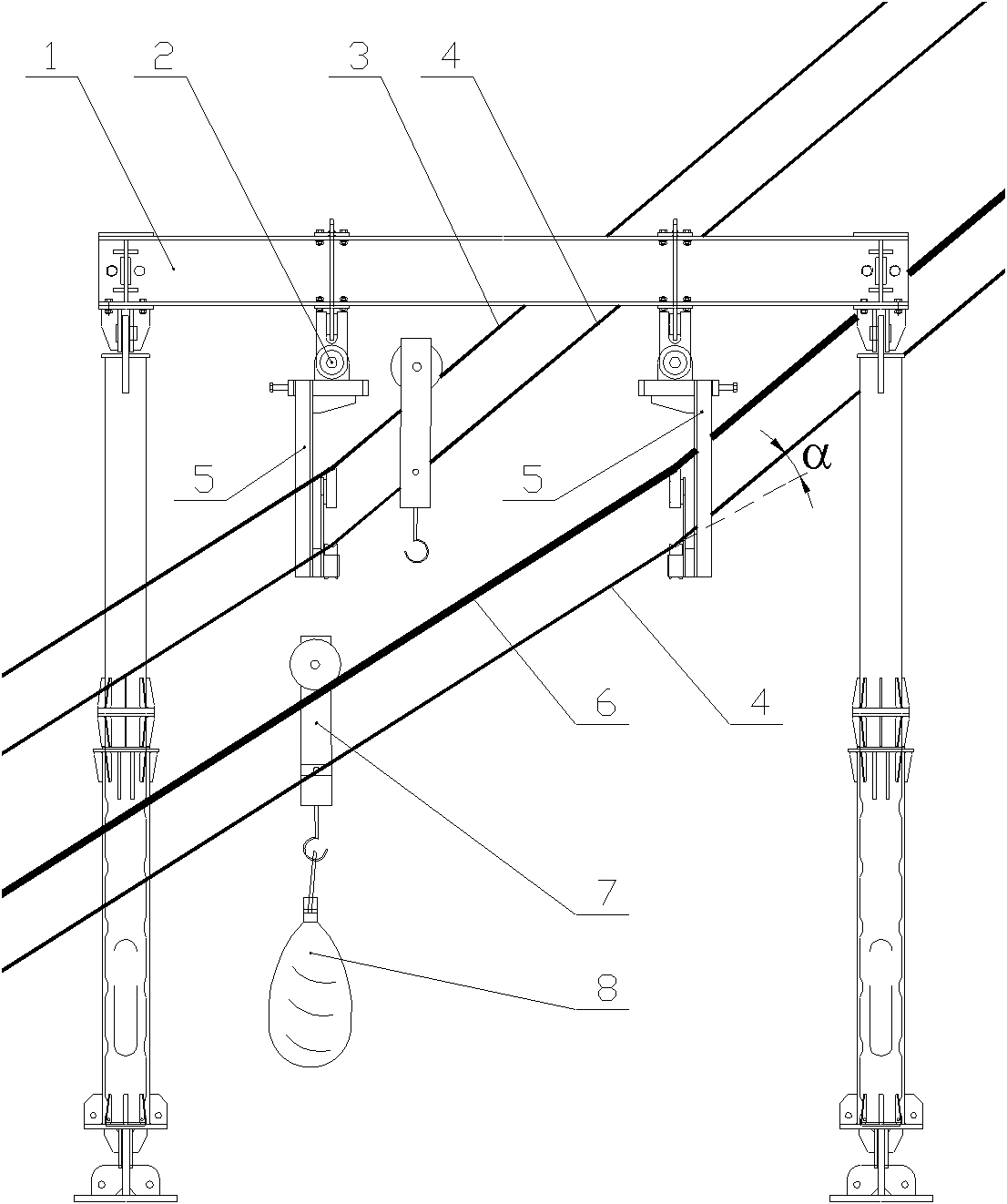

[0027] figure 1 Schematic diagram for the use of freight ropeway racks for transmission lines. When the power transmission line freight cableway is in operation, the bracket is mainly composed of cableway bracket 1, return cable 3, circulating traction cable 4, adjustable cableway hanger 5, load cable 6, running trolley 7, material 8 and other parts. During construction, the cableway support 1 is fixed on the ground, the adjustable cableway hanger 5 is connected with the cableway support 1 through the pin shaft 2, and the return cable 3 and the carrying cable 6 are hung on the support saddle 15 of the adjustable cableway hanger 5 In the groove, the circulating traction cable 4 is hung on the cable wheel 16 of the adjustable cableway hanger 5, the running wheel of the unloaded running trolley 7 walks on the return cable 3, and the running trolley 7 carrying the material 8 Walking on the carrying cable 6, the running trolley 7 is connected and fixed with the circulating tractio...

Embodiment 2

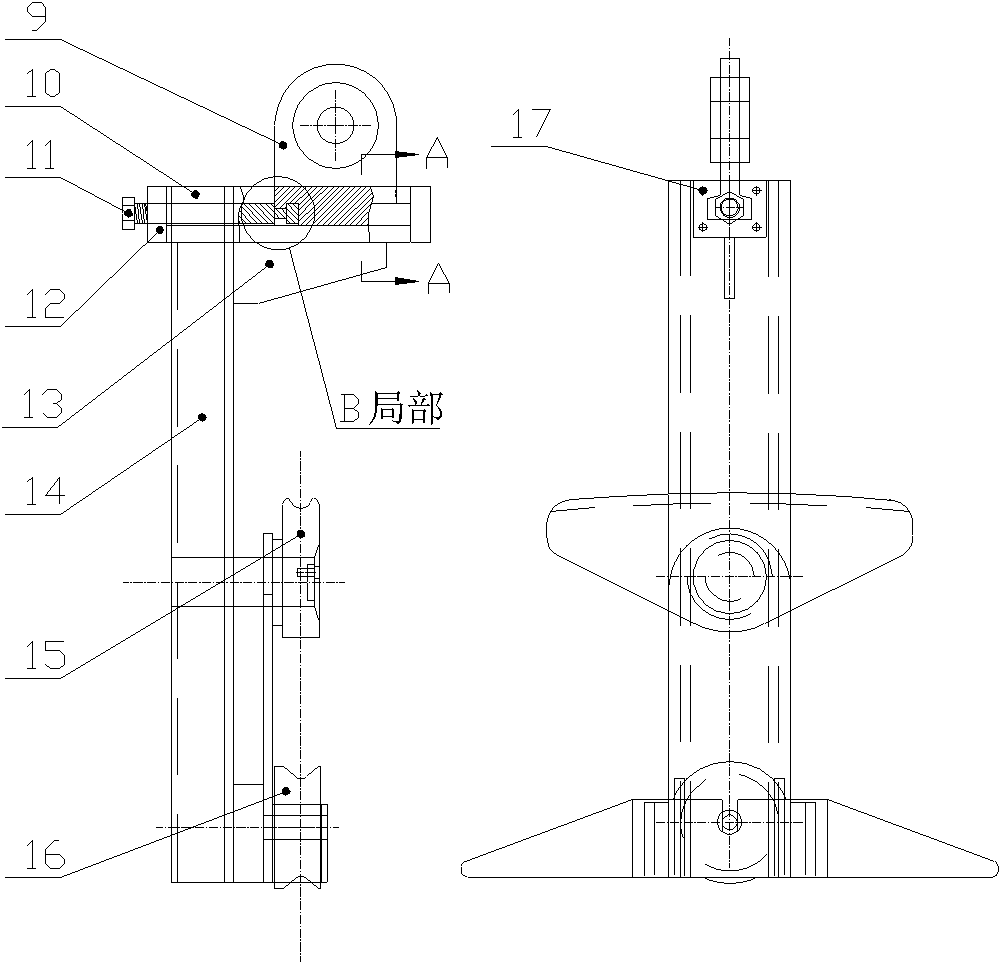

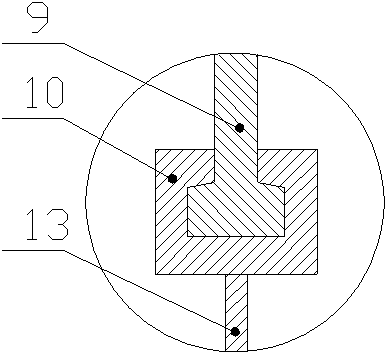

[0029] figure 2 It is a structural schematic diagram of the adjustable cableway hanger. The adjustable cableway hanger 5 mainly includes a hanging plate 9, an adjusting bolt 11, an end plate 12, a reinforcing plate 13, a spreader body 14, a saddle 15, a cable wheel 16 and a fixing bolt 17, and the end plate 12 is provided with a chute 10. Hanger body 14 is vertically arranged with end plate 12, and reinforcing plate 13 is set at the junction of hanging tool body 14 and end plate 12, and the purpose of reinforcing plate 13 setting is to strengthen the connection strength of hanging tool body 14 and end plate 12. The rope saddle 15 and the rope wheel 16 are arranged on the same side of the hanger body 14, the rope saddle 15 is located above the rope wheel 16, and its setting position is on the same side of the hanger body 14 as the hanging plate 9. The upper end surfaces of the cable saddle 15 and the cable wheel 16 are in the shape of grooves. During construction, the load-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com