Test device for engine thermal management system

A thermal management system and test device technology, which is applied in the field of engine thermal management system test devices, can solve the problems of huge investment, model simulation accuracy to be improved, and long cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings, but not as a limitation of the present invention.

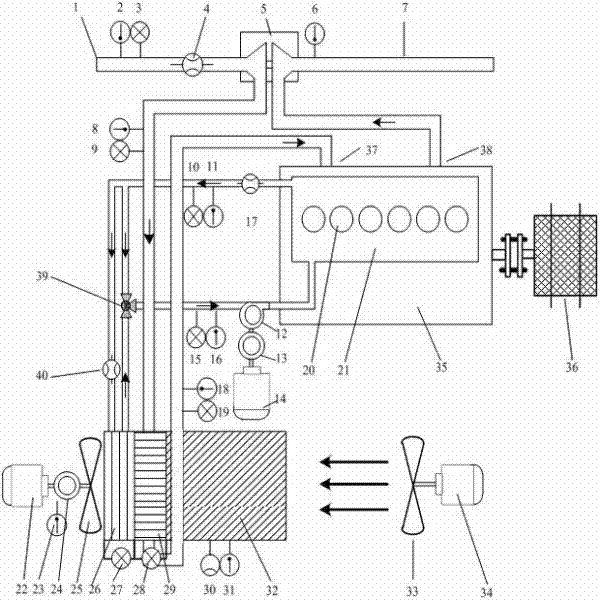

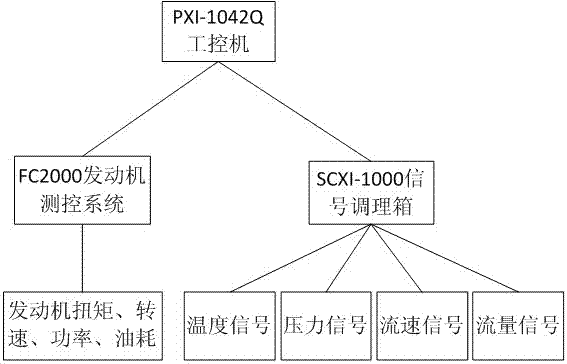

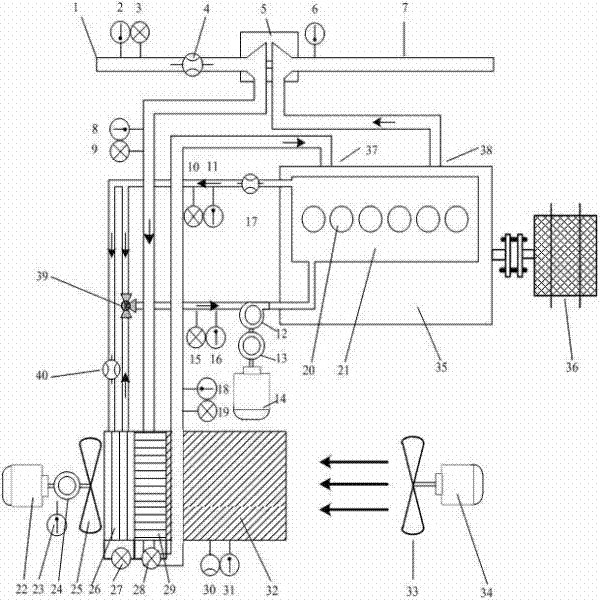

[0018] Such as figure 1 As shown, the engine thermal management system test device includes engine intake pipe 1, first temperature sensor 2, first pressure sensor 3, air mass flow meter 4, exhaust gas turbocharger 5, sixth temperature sensor 6, engine exhaust pipe 7. Second temperature sensor 8, second pressure sensor 9, fourth pressure sensor 10, fourth temperature sensor 11, water pump 12, water pump torque speed sensor 13, water pump variable frequency motor 14, fifth pressure sensor 15, fifth temperature sensor 16. First coolant flow sensor 17, third temperature sensor 18, third pressure sensor 19, engine cylinder 20, engine cooling water cavity 21, fan frequency conversion motor 22, eighth temperature sensor 23, fan torque speed sensor 24, cooling Fan 25, radiator 26, second differential pressure sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com