Distribution network working power supply based on self-energy-gaining coil technology

A working power supply, self-energy technology, applied in electrical components, electromechanical devices, asynchronous induction motors, etc., can solve the problems of no electrical isolation, large voltage and waveform distortion, solar power supply relying on weather conditions, etc., to solve the inrush current , the effect of large starting current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

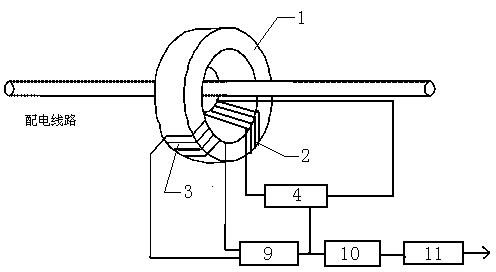

[0020] see figure 1 , a distribution network working power supply based on self-energy harvesting coil technology, including an inductor core 1, a discharge winding 2 and an energy harvesting winding 3 are wound on the inductor core 1, and a discharge module is connected to the discharge winding 2 4. An energy harvesting device is also connected to the energy harvesting winding 3; the energy harvesting device includes a rectification module 9, a filter module 10, and a voltage stabilization module 11 connected in sequence, the rectification module 9 is connected to the above energy harvesting winding 3, and the discharge module is also The rectifier module 9 and the filter module 10 are respectively connected, and the energy harvesting winding is similar to a current transformer, and the energy is harvested through the primary line magnetic induction.

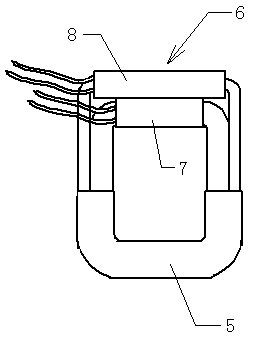

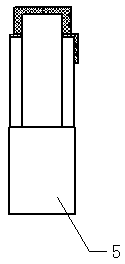

[0021] The inductance core 1 is composed of a first arc-shaped inductance core 5 and a second arc-shaped inductance core 6 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com