Flavor bean curd and production process thereof

A flavor and tofu technology, applied in the production process of flavored tofu products, almond tofu, and flavored tofu fields, can solve problems such as inability to perform high-temperature sterilization, inability to give shelf life to commercialized sales, inability to achieve industrialization, and large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] Embodiment 1, the preparation of almond tofu

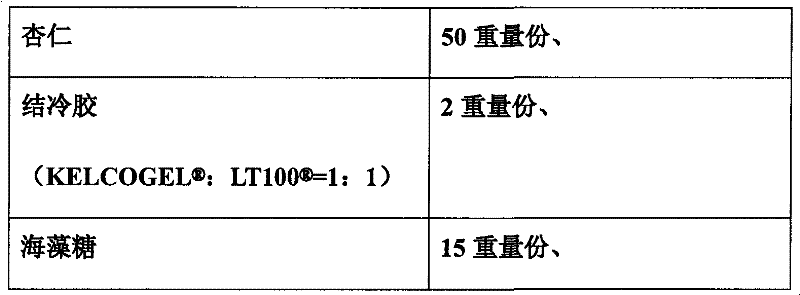

[0104] 1) Ingredients for the gel block part:

[0105]

[0106]

[0107] 2) Preparation process:

[0108] (a) Take the fruit material of formula quantity, use appropriate amount of water (about 5 times the amount of fruit material) to prepare fruit pulp liquid, soak, peel, beat and / or filter residue during the preparation process;

[0109] (b) Take the gellan gum and trehalose in the formula amount, dry mix them, add an appropriate amount of cold water (about 400 parts by weight), stir evenly, and heat and boil;

[0110] (c) Add calcium lactate to the liquid material of step (b), stir evenly, then add the milk of the formula amount and the fruit pulp liquid and the remaining amount of water obtained in step (a), and cook in good time;

[0111] (d) cooling the liquid material obtained in step (c) at room temperature until a gel is formed;

[0112] (e) cutting the gel obtained in step (d), placing the obtained gel bl...

Embodiment 2

[0115] Embodiment 2, the preparation of almond tofu

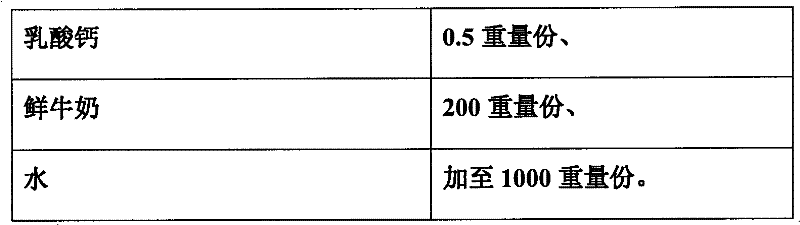

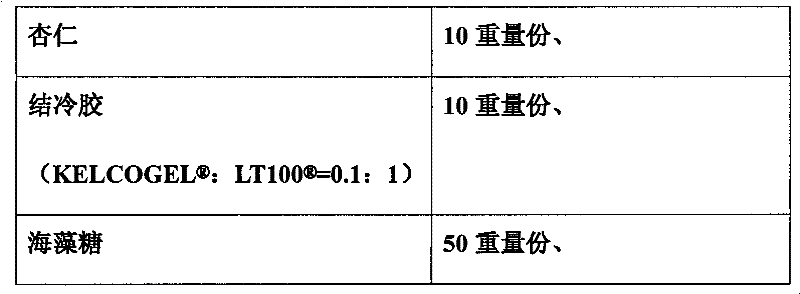

[0116] 1) Ingredients for the gel block part:

[0117]

[0118]

[0119] 2) Preparation process:

[0120] (a) Take the fruit material of formula quantity, use appropriate amount of water (about 5 times the amount of fruit material) to prepare fruit pulp liquid, soak, peel, beat and / or filter residue during the preparation process;

[0121] (b) Take the gellan gum and trehalose in the formula amount, dry mix them, add an appropriate amount of cold water (about 200 parts by weight), stir evenly, and heat and boil;

[0122] (c) Add calcium lactate to the liquid material of step (b), stir evenly, then add the milk of the formula amount and the fruit pulp liquid and the remaining amount of water obtained in step (a), and cook in good time;

[0123] (d) cooling the liquid material obtained in step (c) at room temperature until a gel is formed;

[0124] (e) cutting the gel obtained in step (d), placing the obtained gel bl...

Embodiment 3

[0127] Embodiment 3, the preparation of almond tofu

[0128] 1) Ingredients for the gel block part:

[0129]

[0130]

[0131] 2) Preparation process:

[0132] (a) Take the fruit material of formula quantity, use appropriate amount of water (about 5 times the amount of fruit material) to prepare fruit pulp liquid, soak, peel, beat and / or filter residue during the preparation process;

[0133] (b) Take gellan gum and trehalose in the formula amount, dry mix, add appropriate amount of cold water (about 500 parts by weight), stir evenly, heat and cook;

[0134] (c) Add calcium lactate to the liquid material of step (b), stir evenly, then add the milk of the formula amount and the fruit pulp liquid and the remaining amount of water obtained in step (a), and cook in good time;

[0135] (d) cooling the liquid material obtained in step (c) at room temperature until a gel is formed;

[0136] (e) cutting the gel obtained in step (d), placing the obtained gel block in a package...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com