Seat slide rail mounting device

A slide rail installation and seat technology, which is applied in the field of machining, can solve the problems of lack of fixed workpieces on the assembly table, uncontrollable rotation angle of the assembly table, etc., and achieves the effects of simple structure, avoidance of workpiece movement, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be further described in detail below.

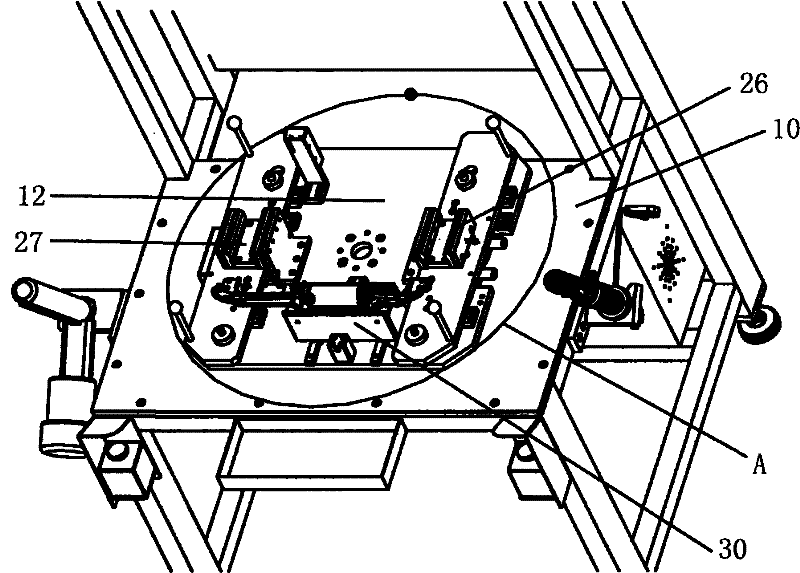

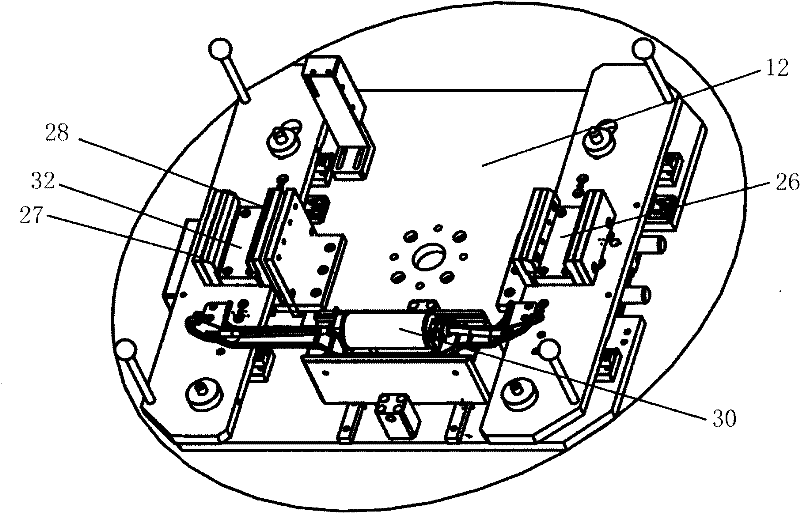

[0016] Such as figure 1 , figure 2 with image 3 As shown, a seat slide rail installation device of the present invention includes a cabinet body 10, the cabinet body 10 is provided with an assembly platform 12 that can rotate horizontally, and the cabinet body 10 is also provided with an inductor ( not shown), and a limiting device 14 that prevents the assembly platform 12 from rotating. The sensor is connected to a programmable controller PLC (not shown), and the limiting device 14 is also controlled by the programmable controller PLC.

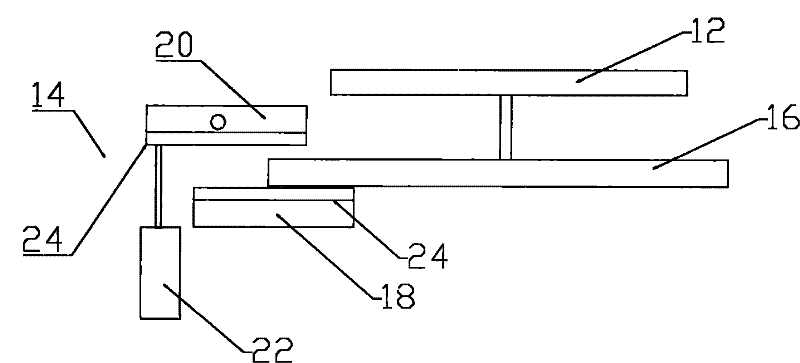

[0017] A circular anti-rotation plate 16 coaxial with the assembly platform 12 is arranged parallel to the bottom of the assembly platform 12 of the first embodiment of the present invention. The anti-rotation clamp 20 and the middle pivot of the upper anti-rotation clamp 20 are connected on the cabinet body 10 , and a vertical first air cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com