Ink jet recording process

An inkjet recording method, inkjet recording technology, applied in the direction of copying/marking method, ink, printing, etc., can solve the problem that the scratch resistance cannot obtain sufficient strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

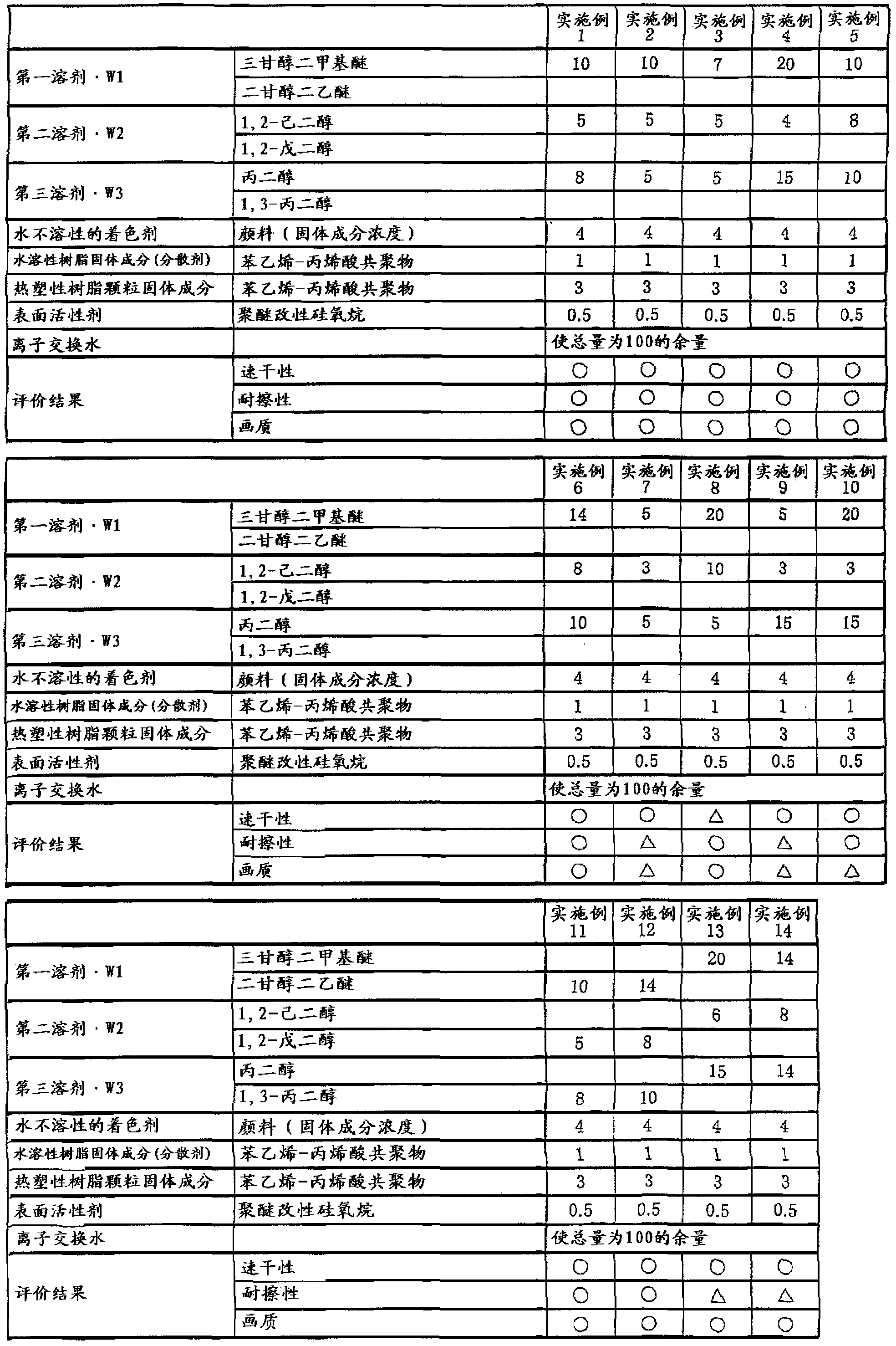

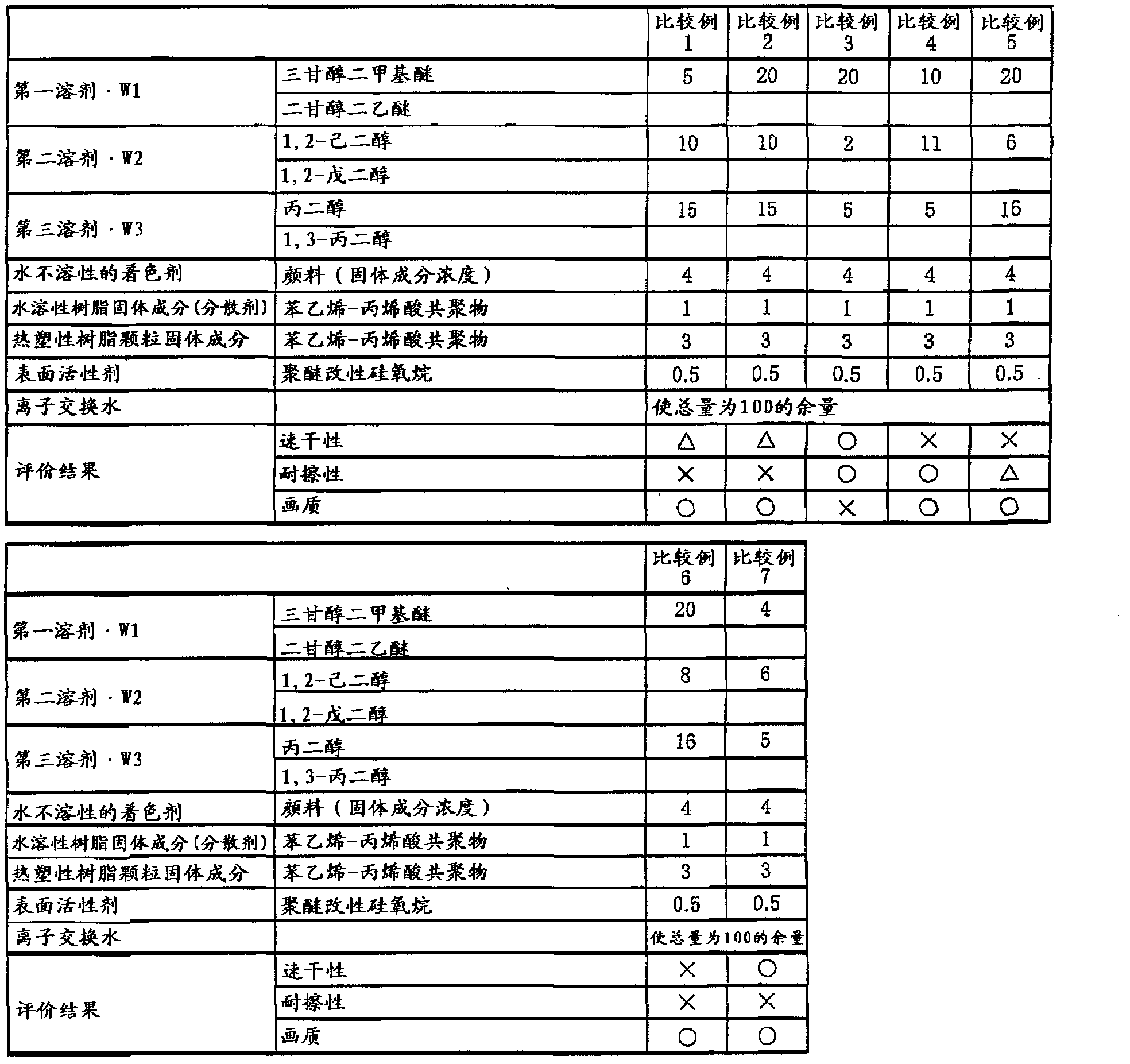

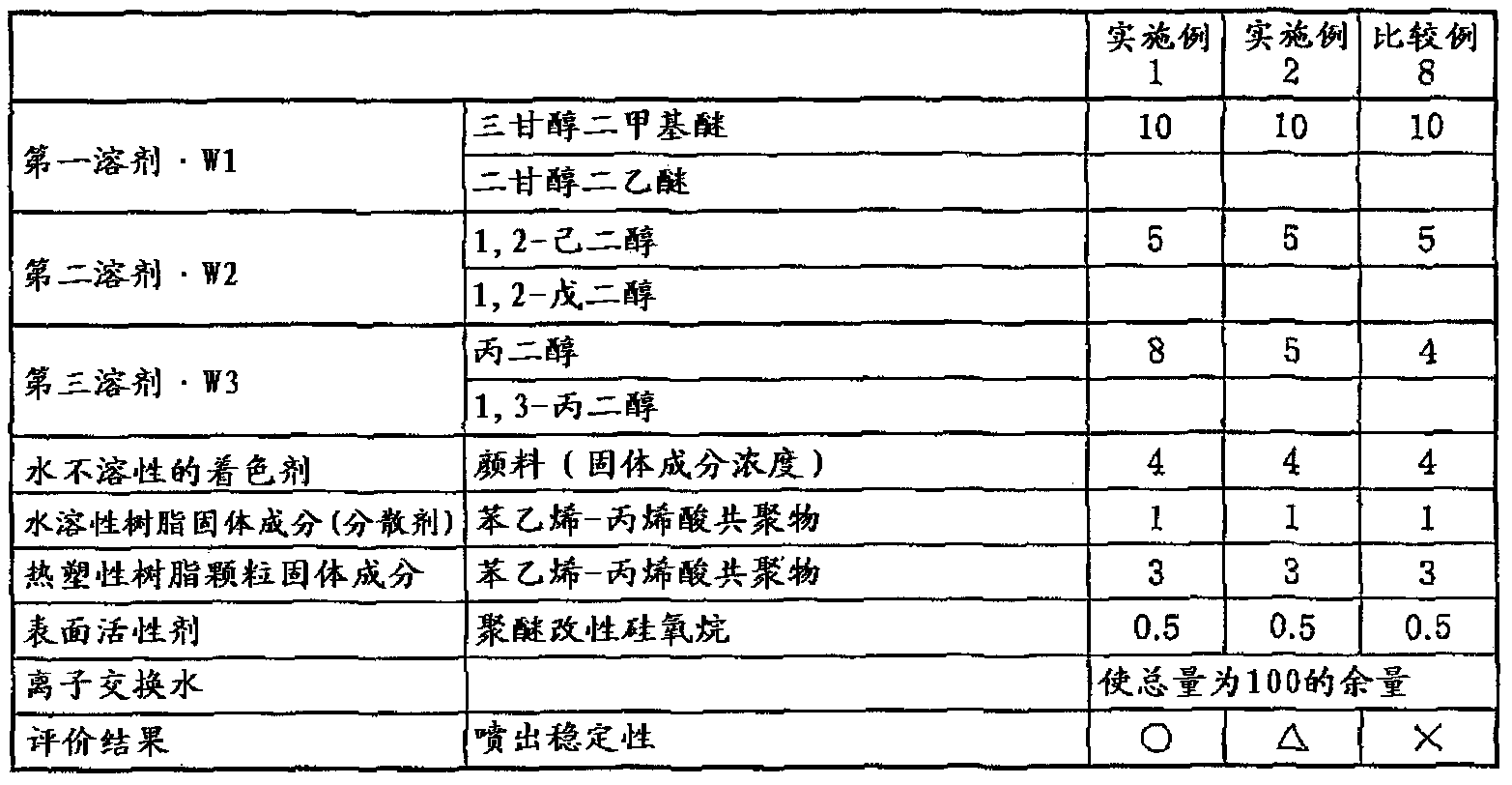

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention will be described below. The embodiments described below are examples for explaining the present invention. In addition, this invention is not limited to the following embodiment, Various modification examples implemented in the range which do not change the summary of this invention are included.

[0027] 1. Inkjet recording method

[0028] An inkjet recording method according to an embodiment of the present invention is characterized in that the inkjet recording method includes: a first step, using an inkjet recording device, heating a recording medium that does not absorb ink or has low ink absorption to 40°C or higher In the temperature range below 60°C, the droplets of the water-based ink composition are ejected; in the second step, the above-mentioned recording medium is heated to a temperature range above 50°C and below 90°C, and the above-mentioned water-based ink jetted on the recording medium is combined The abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com