Anti-counterfeiting self-locking limit bottle cap

A bottle cap and self-locking technology, which is applied in the field of bottle caps, can solve the problems of large tolerance error of the inner diameter of the bottle mouth, difficulty in firing ceramic bottle caps, and difficulty in making threads, etc., and achieves good liquid sealing, beautiful appearance, and good for storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

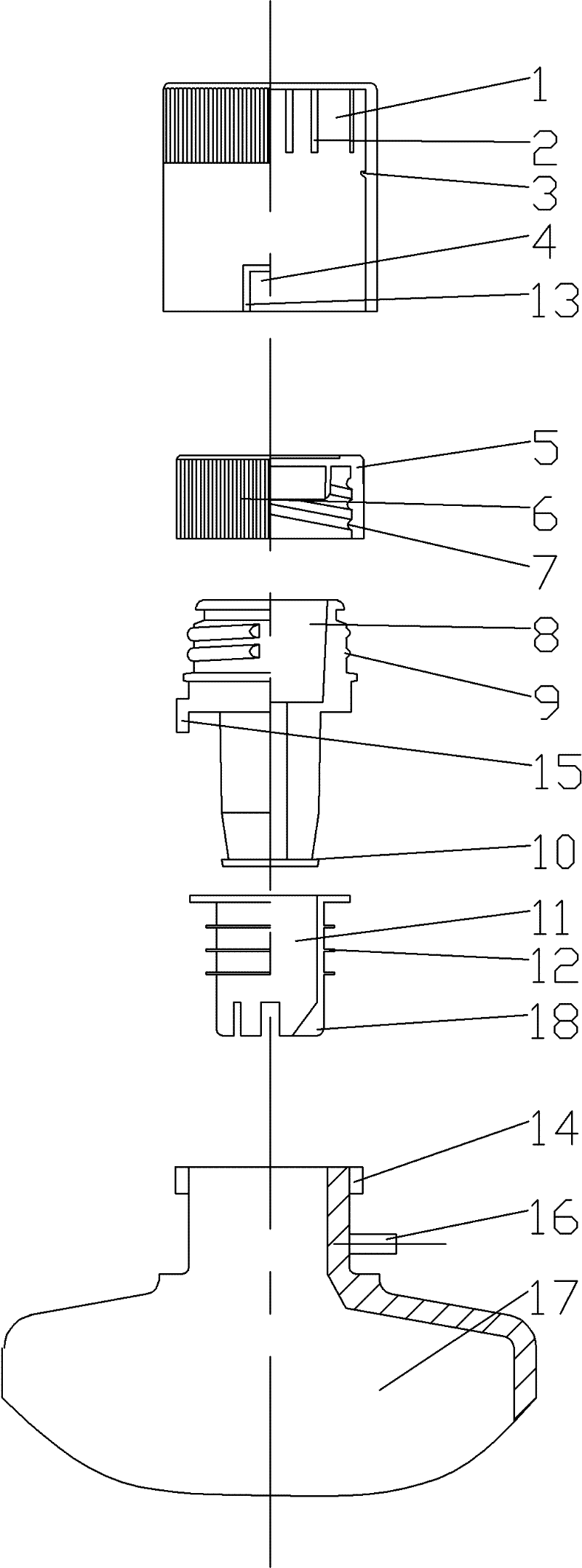

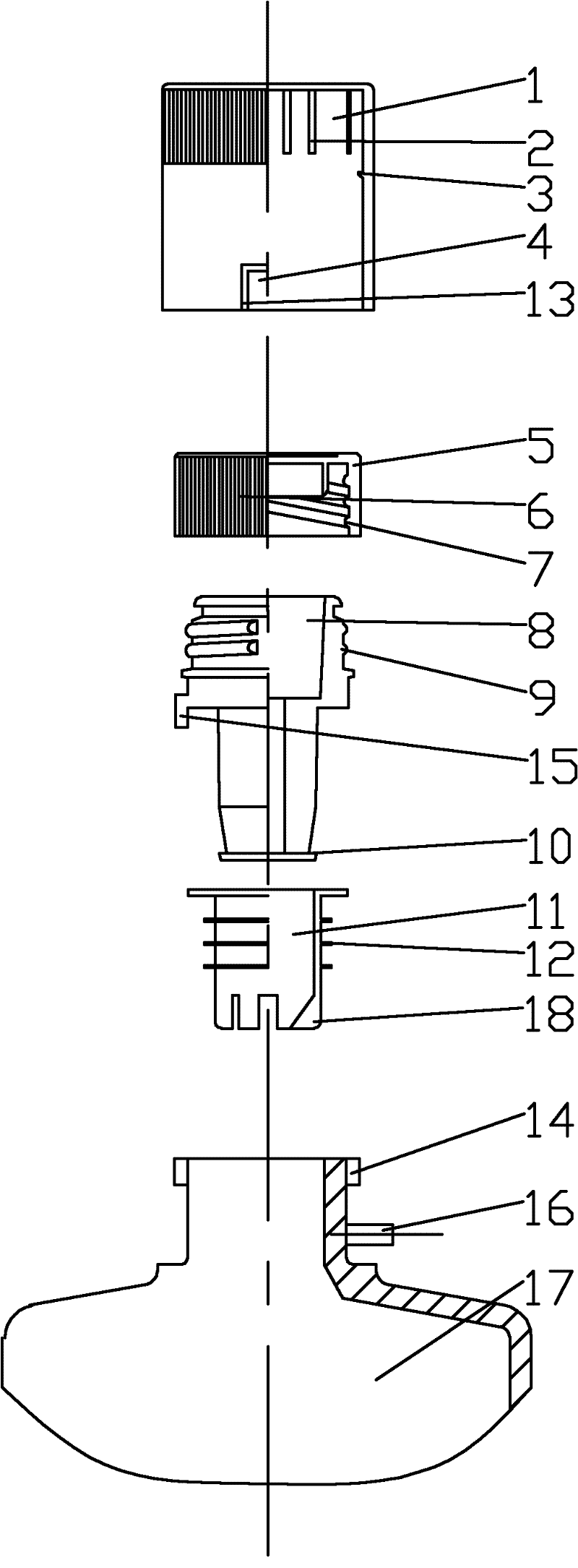

[0015] Such as figure 1 Among them, an anti-counterfeit self-locking limit bottle cap, the inner cap 5 is installed in the outer shell 1, the inner cap 5 is connected with the connecting cap 8 through threads, and the outer surface of the lower end of the connecting cap 8 cooperates with the inner surface of the inner plug 11; The connecting cover 8 is hollow, the upper end is provided with threads, the middle part is provided with at least one anti-rotation strip 15, the lower end is provided with a tapered section, and the tapered section is provided with a detachment groove 10; the outer surface of the inner plug 11 is provided with a plurality of The lower end of the sealing ring 12 is provided with a plurality of wedges 18 .

[0016] The wedges 18 are evenly distributed on the circumference of the lower end of the inner plug 11, the outer side of the wedges 18 is parallel to the axis of the inner plug 11, and the inner side shrinks toward the axis.

[0017] The outer sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com