Spiral toilet blow-off pipe

A sewage pipe and spiral technology, which is applied in the field of sanitary ware, can solve the problems that the diameter of the pipe cannot be made too thick, the straight part of the S pipe is short, and the negative pressure is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

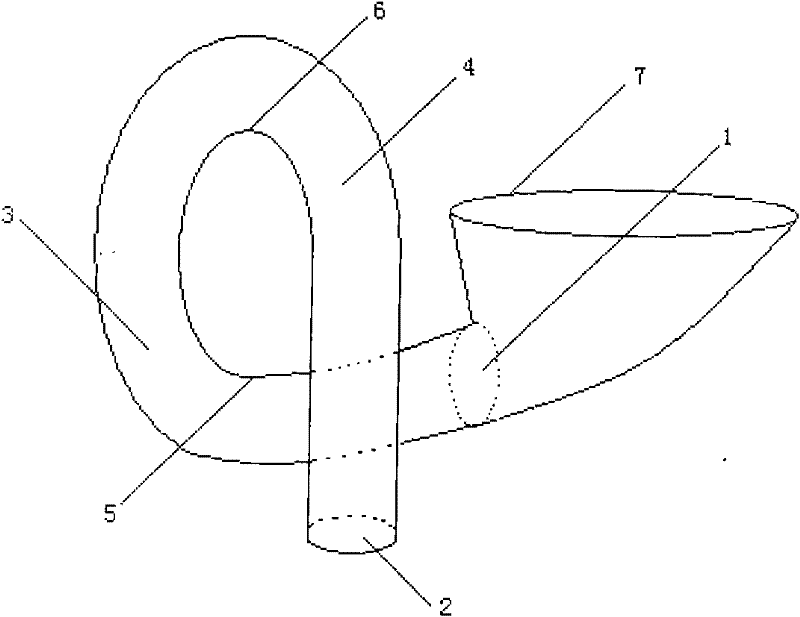

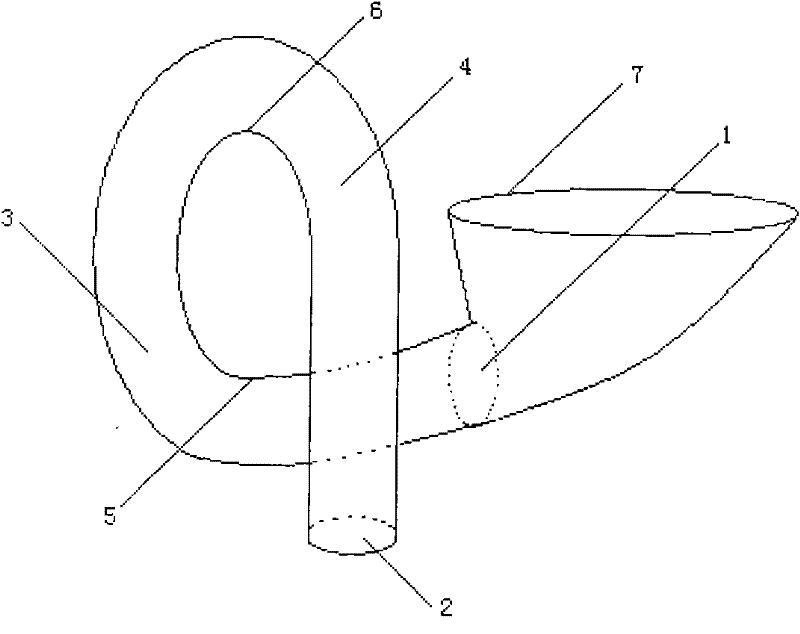

[0022] figure 1 The specific implementation manner of the spiral toilet sewage pipe of the present invention is shown. The entrance section 1, the top-spin section 3, the down-spin section 4, and the outlet section 2 form a staggered approximate spiral ring. As long as the pipe wall is smooth and the inner wall of the pipe is smooth, the thickness and shape of the pipe can be adjusted arbitrarily. After washing the bedpan 7 with water with a certain level of potential energy, the inertia of the water flow forms a vortex in the interval between the inlet section 1 and the upturn section 3. Because of the extrusion of the subsequent water flow, the dirt in the bedpan rolls down with the vortex flow. The bottom wall 6 at the highest point of the rotary section is discharged from the outlet section 2 smoothly. The end position of the outlet section 2 can be adjusted arbitrarily according to the position of the water outlet distance of the building. The depth of toilet water seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com