Method for manufacturing multi-cylinder lock bit

A core lock and lock head technology, applied in the field of locks, can solve the problems of lack of ability to resist technical confrontation and anti-violence opening, simple technical content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] (For manufacturers who can produce cross-shaped mechanical pin locks, the blanks they have and the necessary production technical conditions, and the description of the implementation of the three-core lock manufacturing plan).

[0050] 1. Material preparation: take a certain specification such as image 3 Cross lock shown and matching as figure 1 A set of lock cylinder blanks as shown;

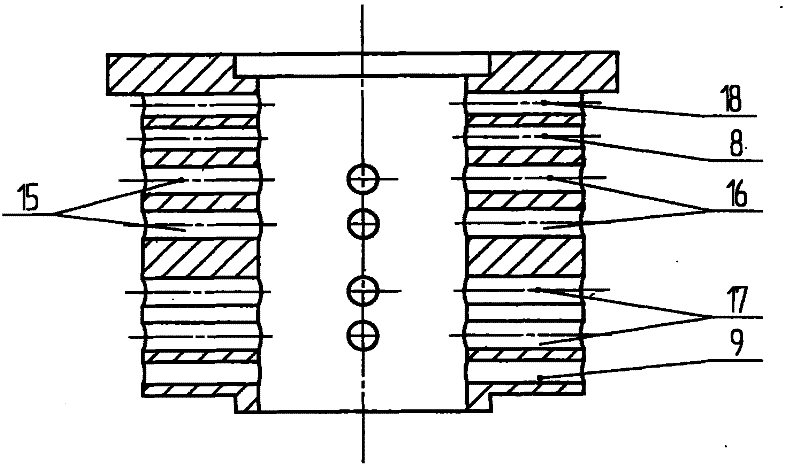

[0051] 2. Manufacture of lock cylinder: such as figure 2 As shown, the upper lock core 4 is composed of the lock core step shoulder 20, the lock core positioning melting groove 13, the outer lock core pin hole 10 and the upper lock core pin hole 11; the lower lock core 5 is composed of the lower lock core pin hole 12, The lower lock core positioning melting groove 14 and the tongue snap ring groove 19 constitute, press figure 2 The marked positions are processed into upper and lower lock core bodies.

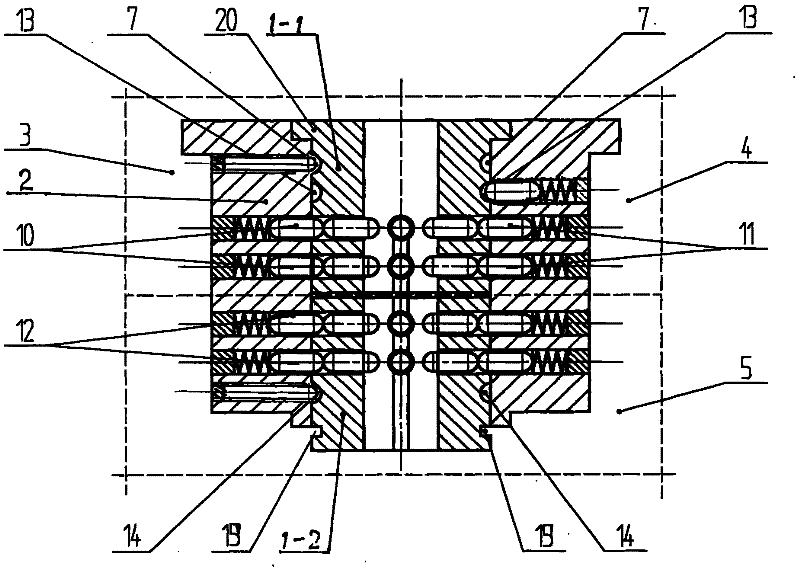

[0052] 3. Lock housing processing, such as image 3 Shown:

[0053] ① Accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com