Method for detecting whole straightness of steel pipe

A steel pipe, the overall technology, applied in the field of detection, can solve the problem of not being able to measure the overall straightness of the steel pipe effectively and quickly, and achieve the effect of increasing speed and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

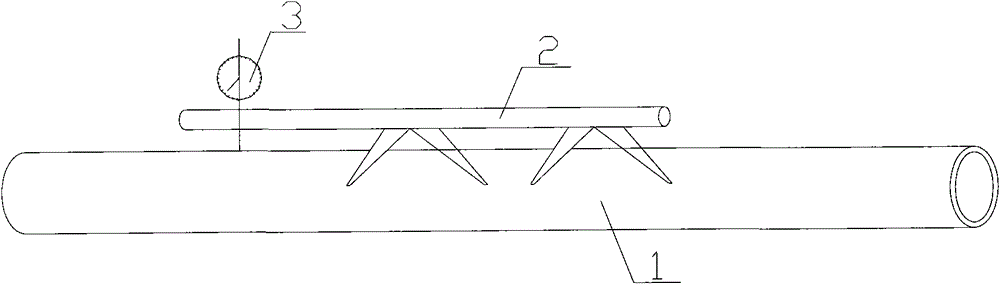

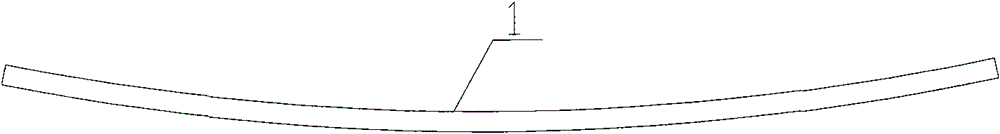

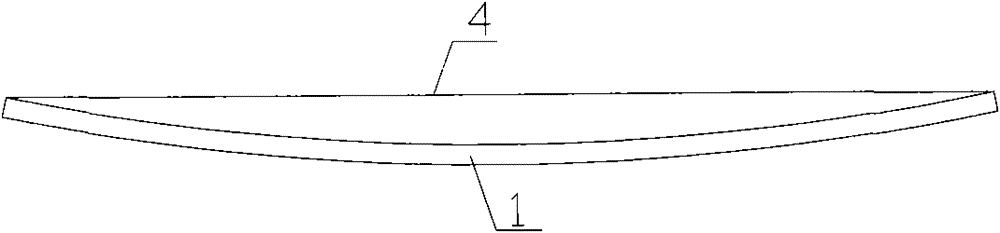

[0045] The method for detecting the overall straightness of steel pipes according to the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0046] Such as Figure 5 As shown, the preset steel pipe straightness reference value in this embodiment is 15 mm, and the radius R of the steel pipe 1 to be tested is 59 mm. When using this detection method to detect the overall straightness of the steel pipe 1: first, set the guide rail 6 The angle α between the horizontal plane and the horizontal plane is 14.2 degrees; then the steel pipe 1 to be tested is placed on the inclined guide rail 6, and the steel pipe 1 has a tendency to roll down the inclined guide rail 6 under the action of gravity G; Assuming that the steel pipe straightness reference value is 15 mm as a reference, judge the straightness of the steel pipe 1 to be tested, and the specific judgment results are shown in Table 1.

[0047] Table 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com