Sealing device for guide groove of sealing-tape machine

A technology of sealing device and material guide groove, which is applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems affecting the health of on-site operators, time-consuming and laborious replacement of side sealing plates, frequent replacement of sealing bead, etc., and achieves a simple connection method Moreover, the replacement is convenient and quick, and the effect of solving the problem of dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

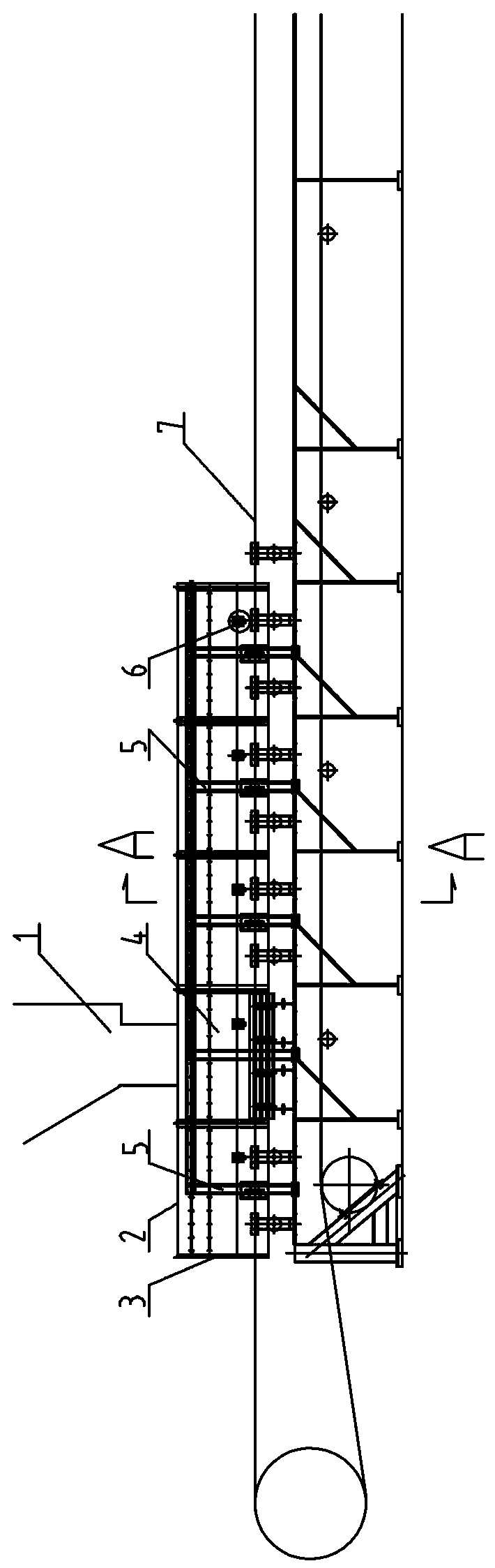

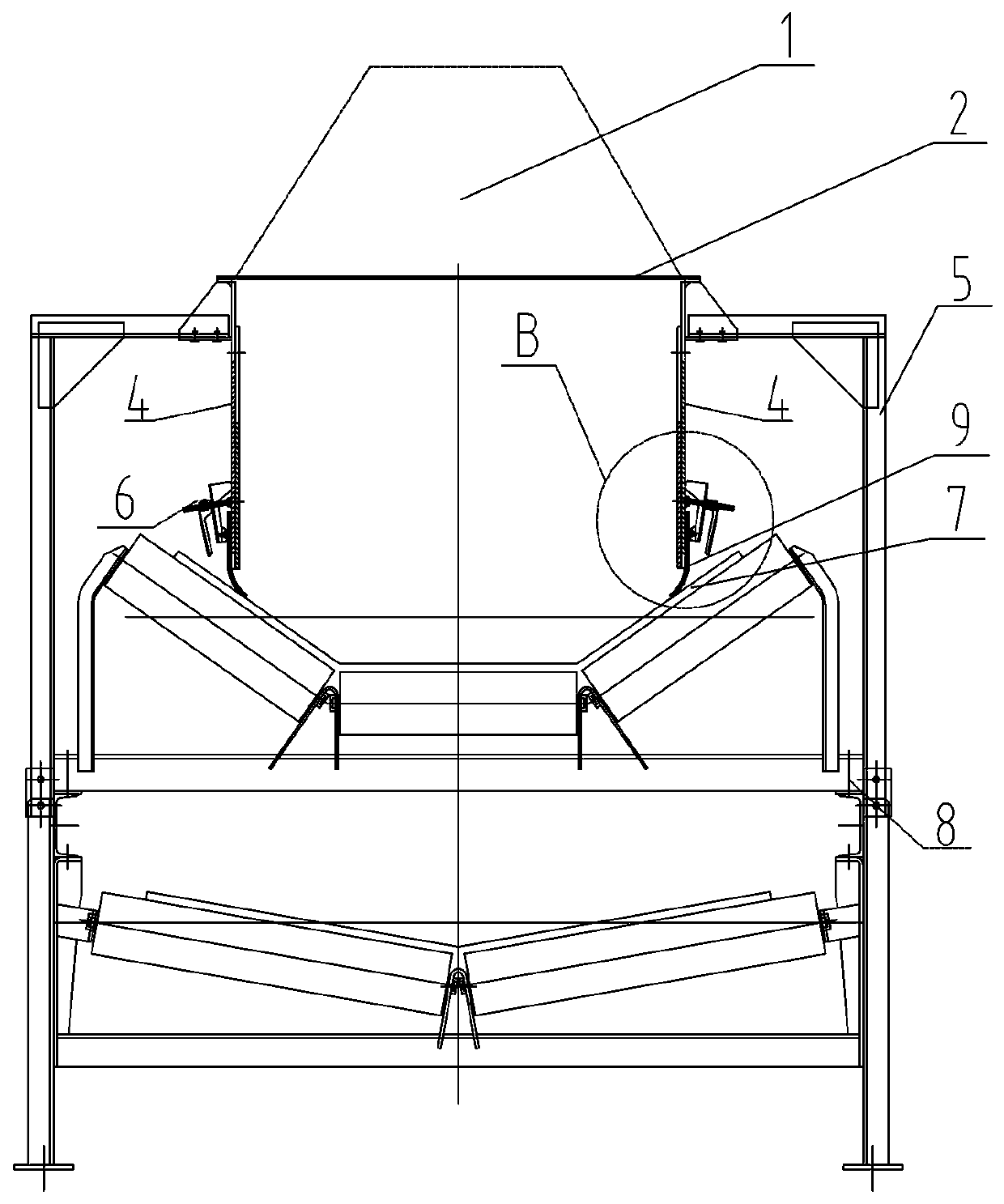

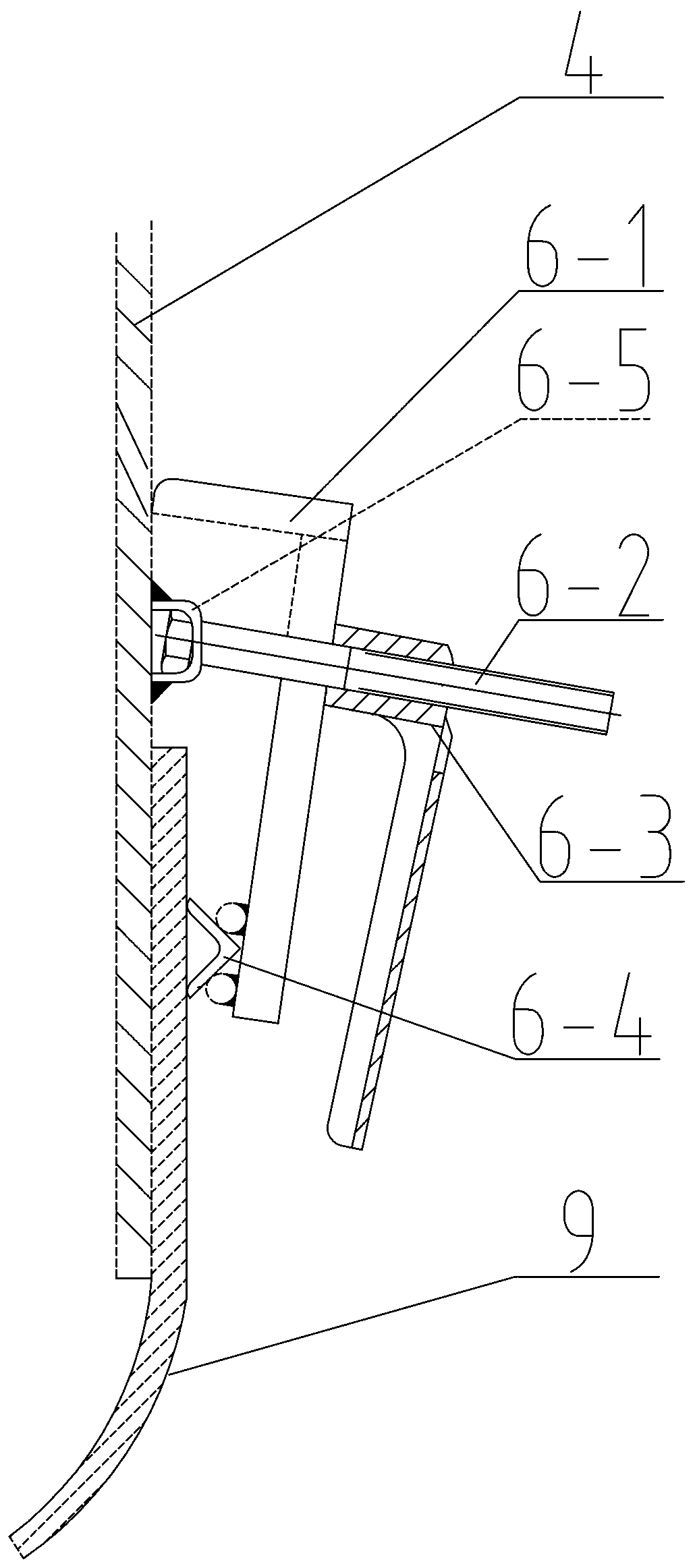

[0022] Such as Figure 1-Figure 3 As shown, a kind of sealing device used for the guide groove of the belt conveyor of the present invention includes: a guide plate 2 communicated with the funnel 1, two guide groove side plates 4, a rear baffle plate 3 and a front curtain. Feed trough, the belt conveyor located below the material guide trough and the sealing and dust-proof device respectively arranged between the two material guide trough side plates 4 and the tailgate 3 and the belt conveyor, the described material guide trough is an upper closed trough body, the guide groove is installed on the middle frame 8 of the tape machine through the bracket 5, and it is characterized in that: the sealing and dustproof device is composed of a locking assembly 6 and a rubber sealing swash plate 9,

[0023] The locking assembly includes a bolt rod 6-2, an L-shaped pressing plate 6-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com