Sound sensor with electromagnetic wave receiver

A sound sensor, electromagnetic wave technology, applied in the direction of sensors, electrical components, transducer circuits, etc., can solve the problem of short circuit of sound sensors, and achieve the effect of reducing the size, reducing the packaging difficulty, and improving the packaging yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further illustrate the technical means and effects that the present invention adopts to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, Features and their functions are described in detail below.

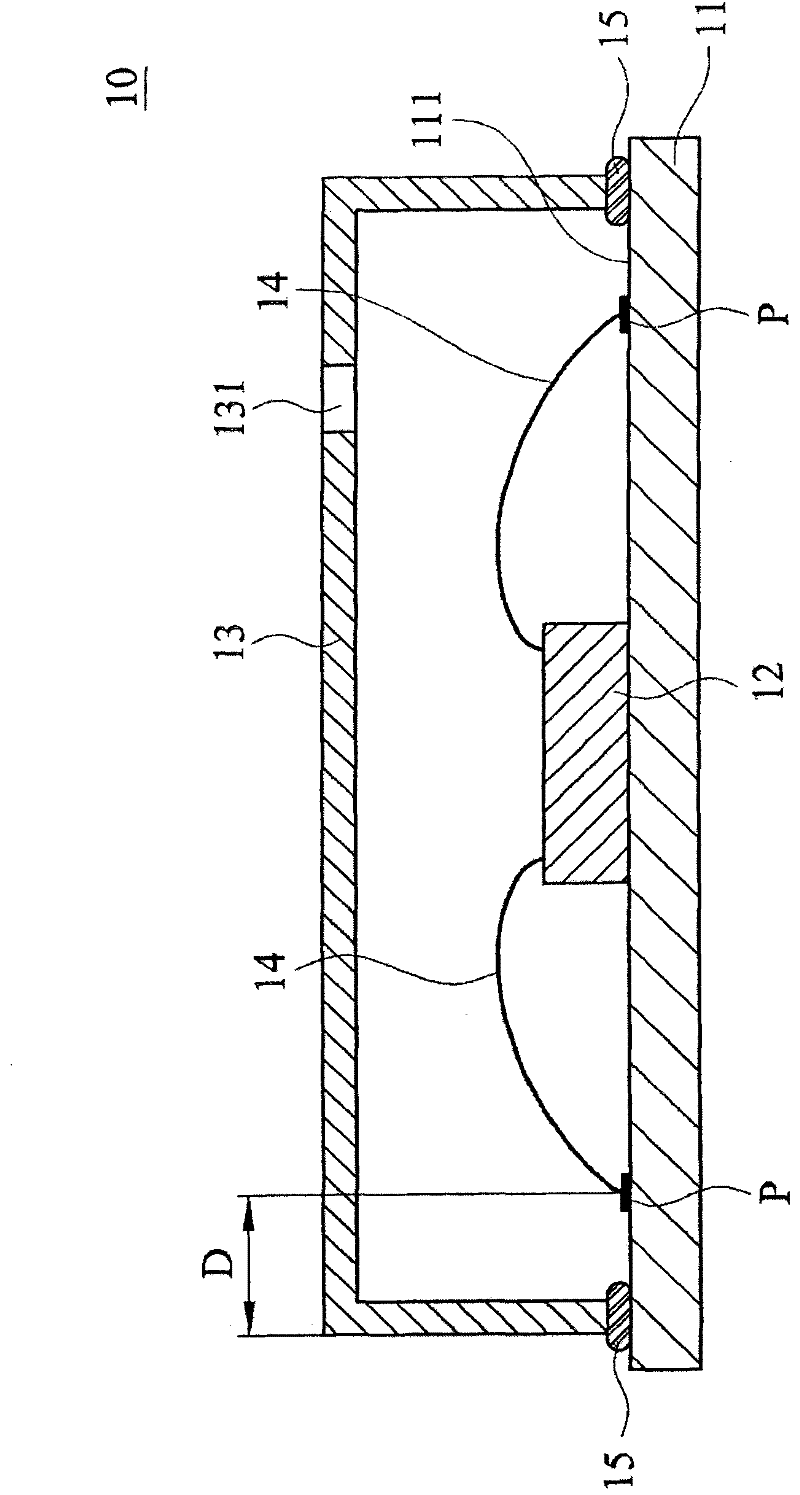

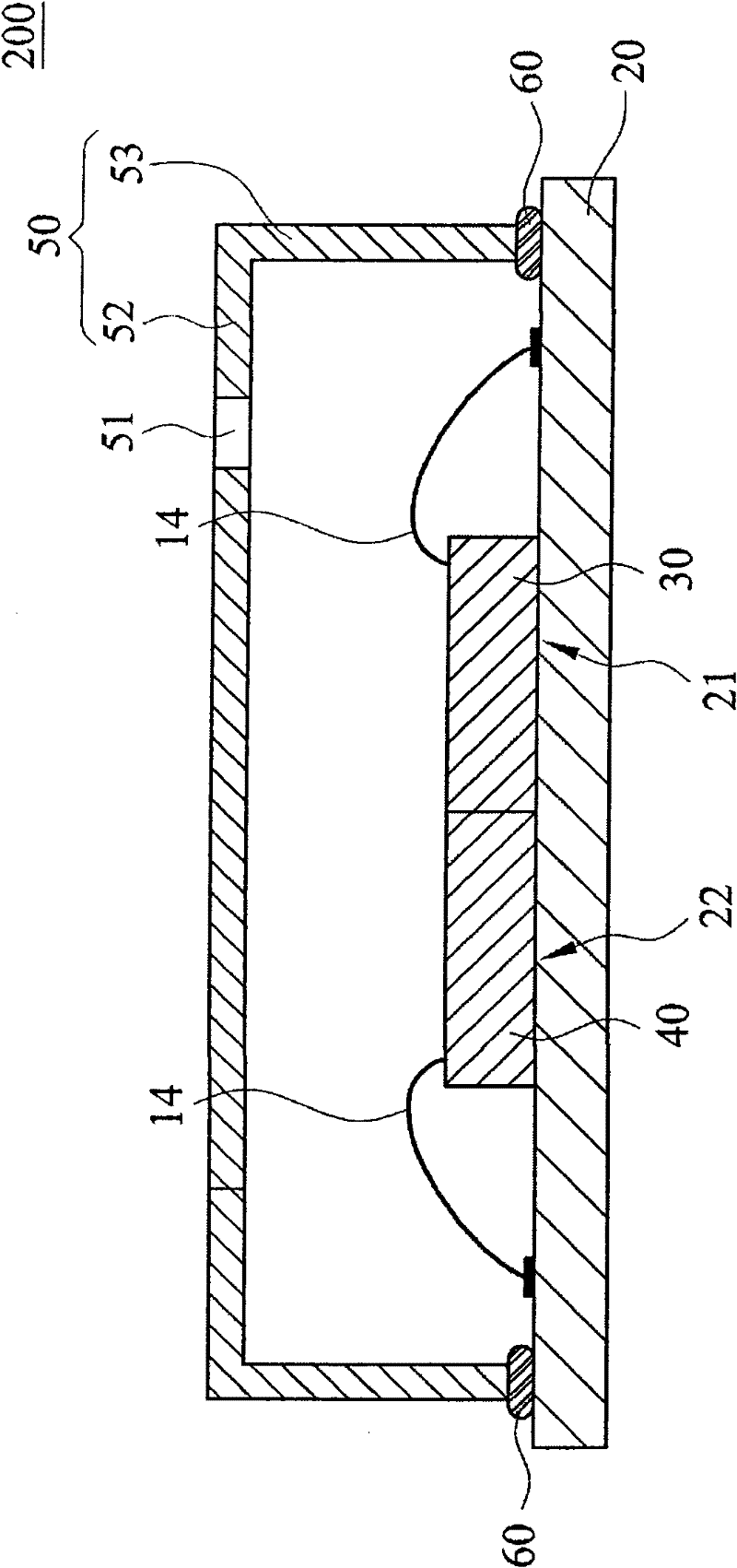

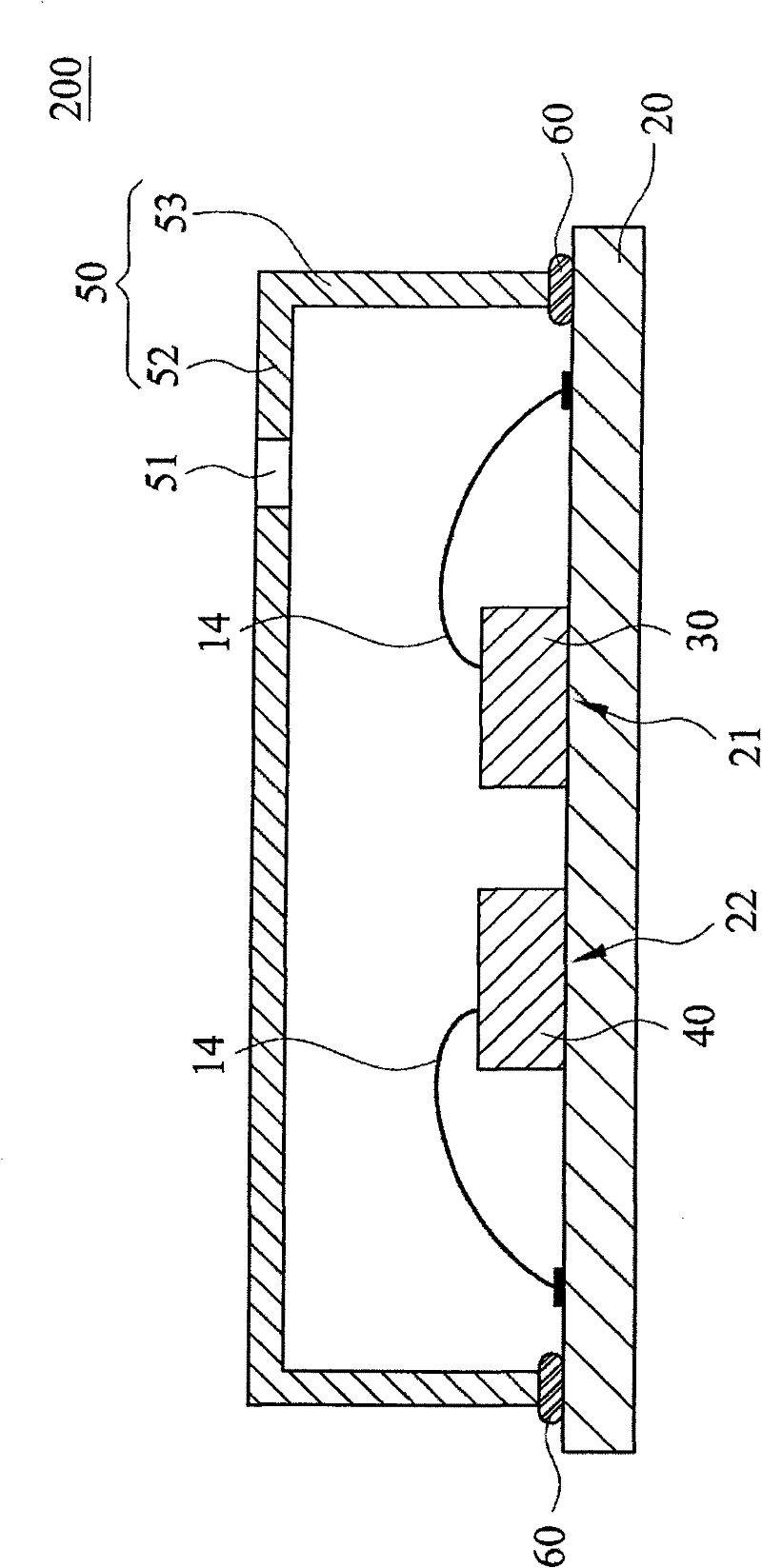

[0044] Figure 2A It is a cross-sectional embodiment diagram of an acoustic sensor 200 with an electromagnetic wave receiver 40 of the present invention. Figure 2B It is a cross-sectional embodiment diagram of another acoustic sensor 200 with an electromagnetic wave receiver 40 of the present invention. image 3 for Figure 2A The top view example diagram. Figure 4AIt is a schematic cross-sectional view of a MEMS microphone 30 of the present invention. Figure 4B It is a schematic cross-sectional view of an electromagnetic wave receiver 40 of the present invention. Figure 5 It is a cross-sectional embodiment diagram of an acoustic sensor 20...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap