Heat removal device of communication electrical appliance

A technology for heat removal devices and electrical appliances, which is applied in cooling/ventilation/heating transformation, chassis/cabinet/drawer parts, etc., to avoid interference, avoid influence, and improve the efficiency of air conditioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

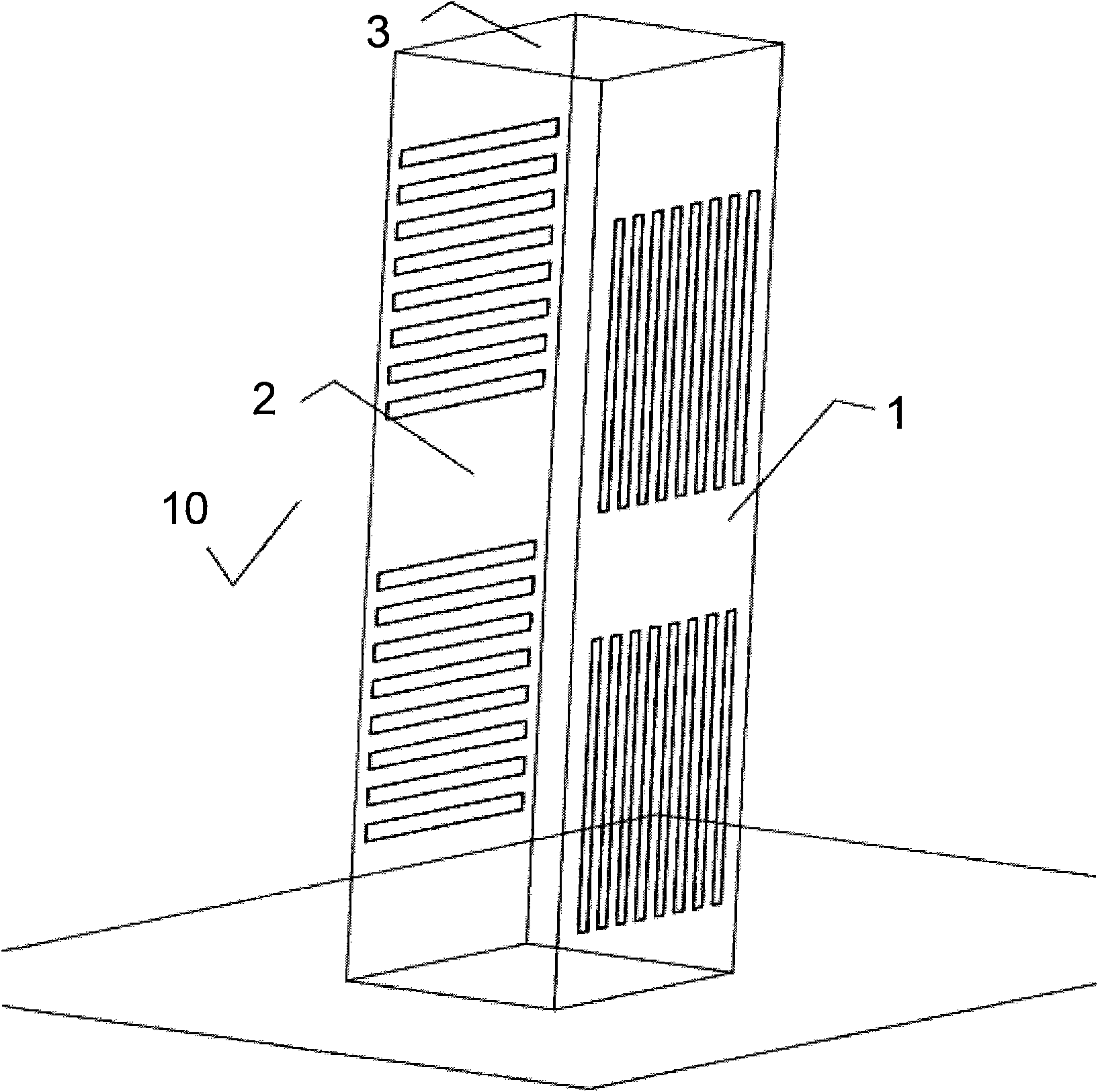

[0014] This creation discloses a heat exhaust device for communication appliances, and the communication appliances are arranged in an electrical cabinet. figure 1 The three-dimensional schematic diagram of the cabinet 10 in the present invention is shown. The common cabinet is a rectangular parallelepiped with a certain height, which includes: the inlet end face 1 for entering the cooling gas and the exhaust end face 2 for discharging the heating gas, and the top 3 of the cabinet. Usually the cabinet basically provides protection and support for a pair of internal equipment in a closed structure.

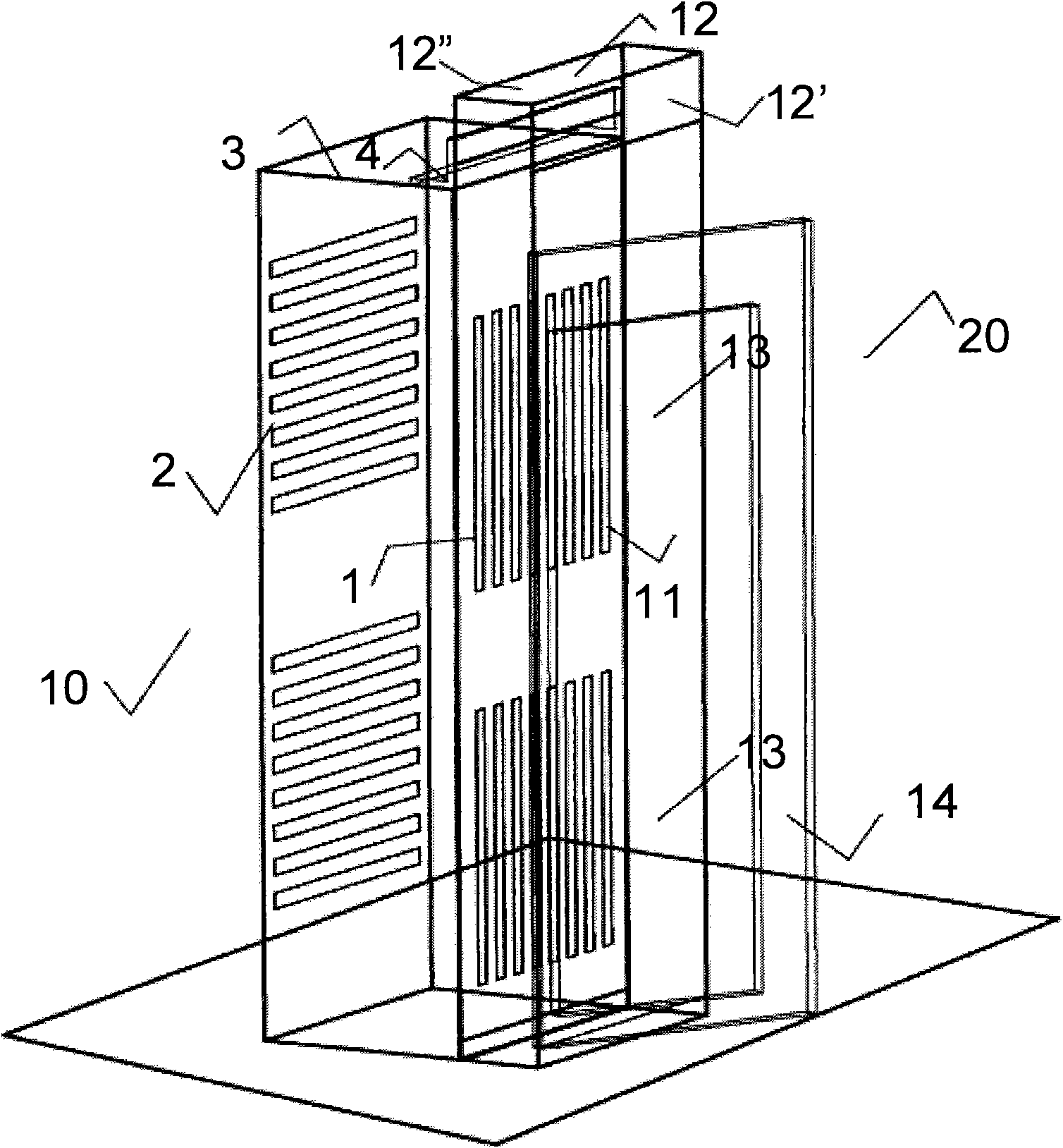

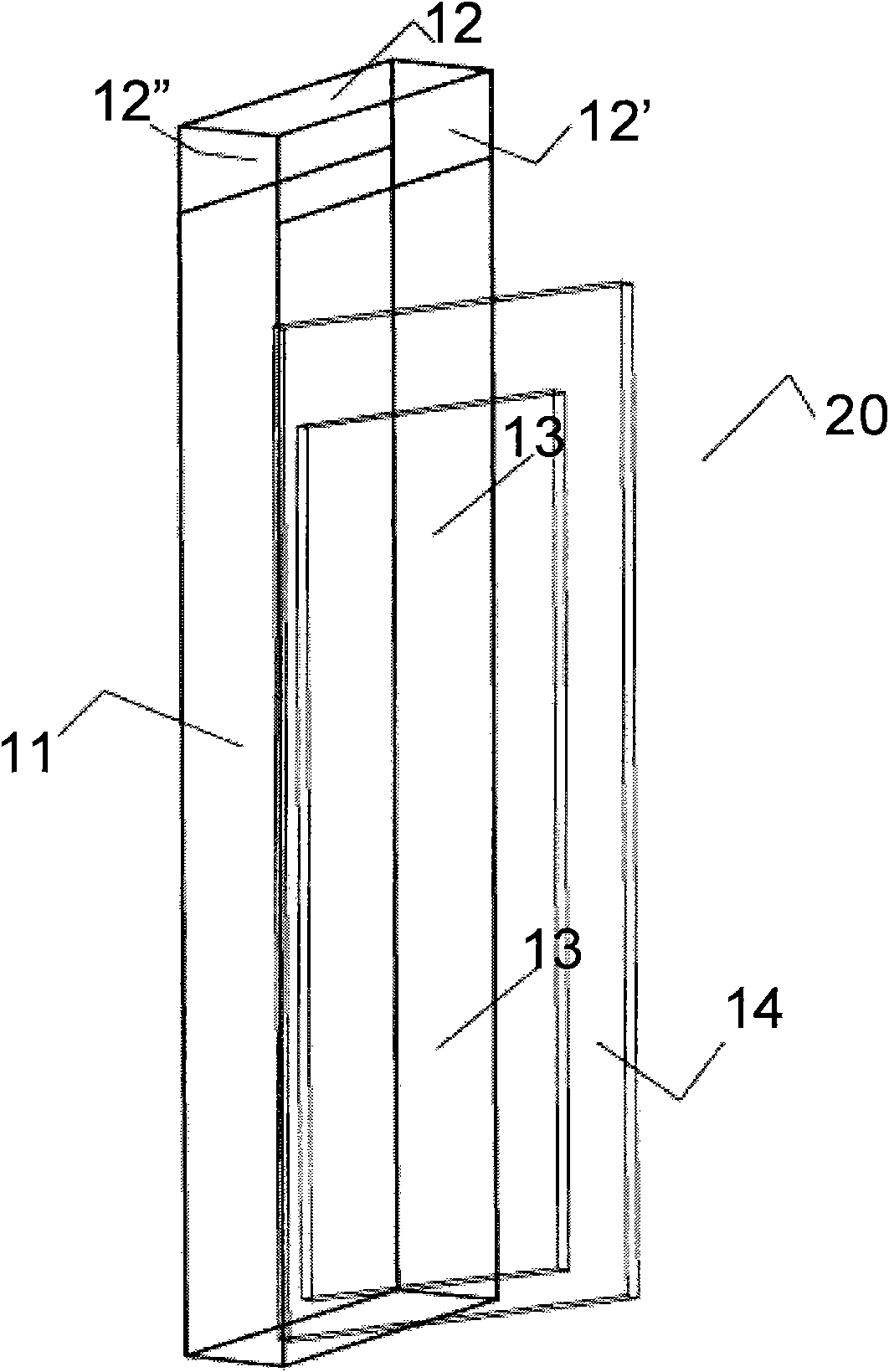

[0015] figure 2 It is a three-dimensional schematic diagram of the cabinet in which the device is installed in the present invention. This figure is an example of the device 20 installed on the inlet end face 1 where the cooling gas enters. It should be pointed out that the exhaust end face 2 installed on the cabinet 10 to discharge the heating gas also has a similar structure an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com