Low-carbon sulphur free-cutting steel

A technology of free-cutting steel and carbon-sulfur, which is applied in the field of low-carbon-sulfur free-cutting steel, and can solve problems such as improvement of machinability without special consideration, insufficient control of sulfide, and failure to control the form of sulfide.

Inactive Publication Date: 2011-11-16

JFE BARS & SHAPES CORP

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] However, in the free-cutting steel described in Patent Document 1, the amount of oxygen is limited to 0.008 mass% or less, but only by reducing the amount of oxygen, the control of the form of sulfide is insufficient, and there are also extended sulfides.

In the free-cutting steels described in Patent Documents 2 and 3, the amount of Si is limited to 0.1 mass% or less, but it is used as a deoxidizer, and it is a component composition that has not been particularly considered for the improvement of machinability.

In addition, in the free-cutting steel of Patent Document 4, although a large amount of S is added, the form of sulfide cannot be controlled.

[0009] Therefore, it cannot be said that the free-cutting steels described in Patent Documents 1 to 4 have sufficient machinability.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

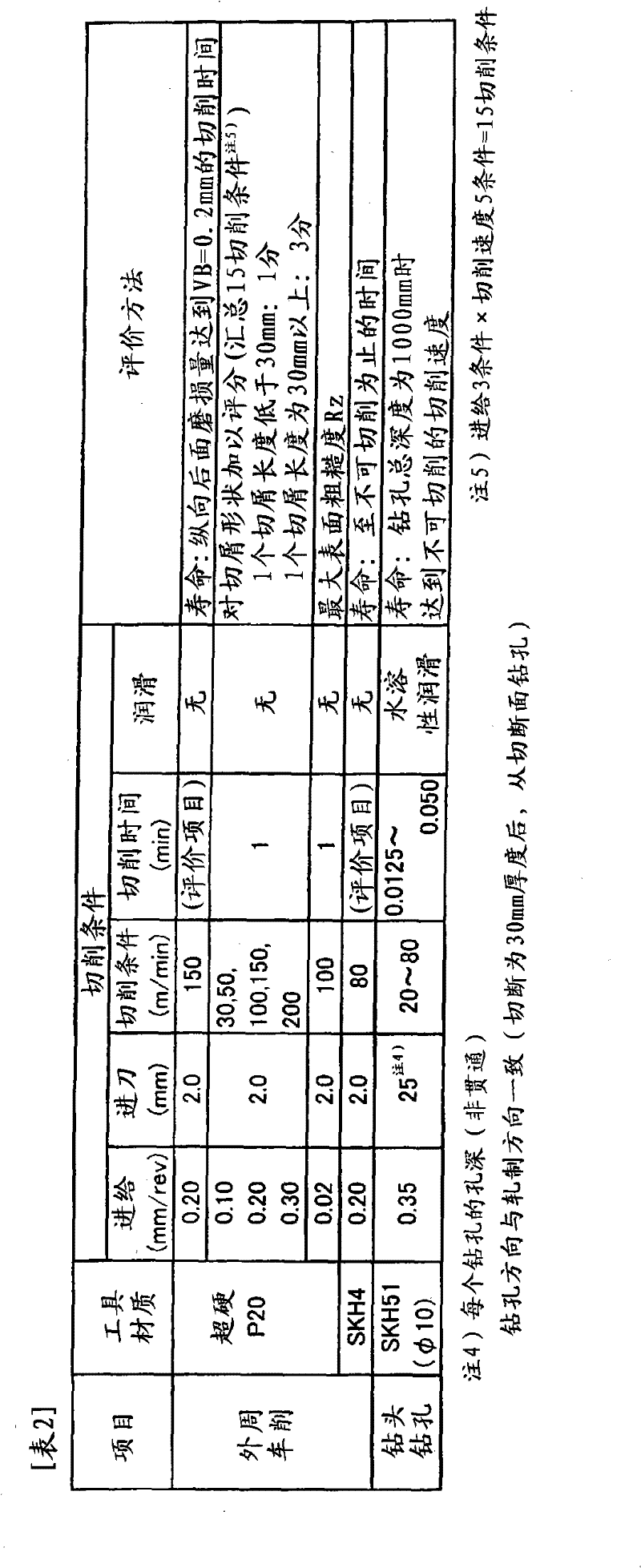

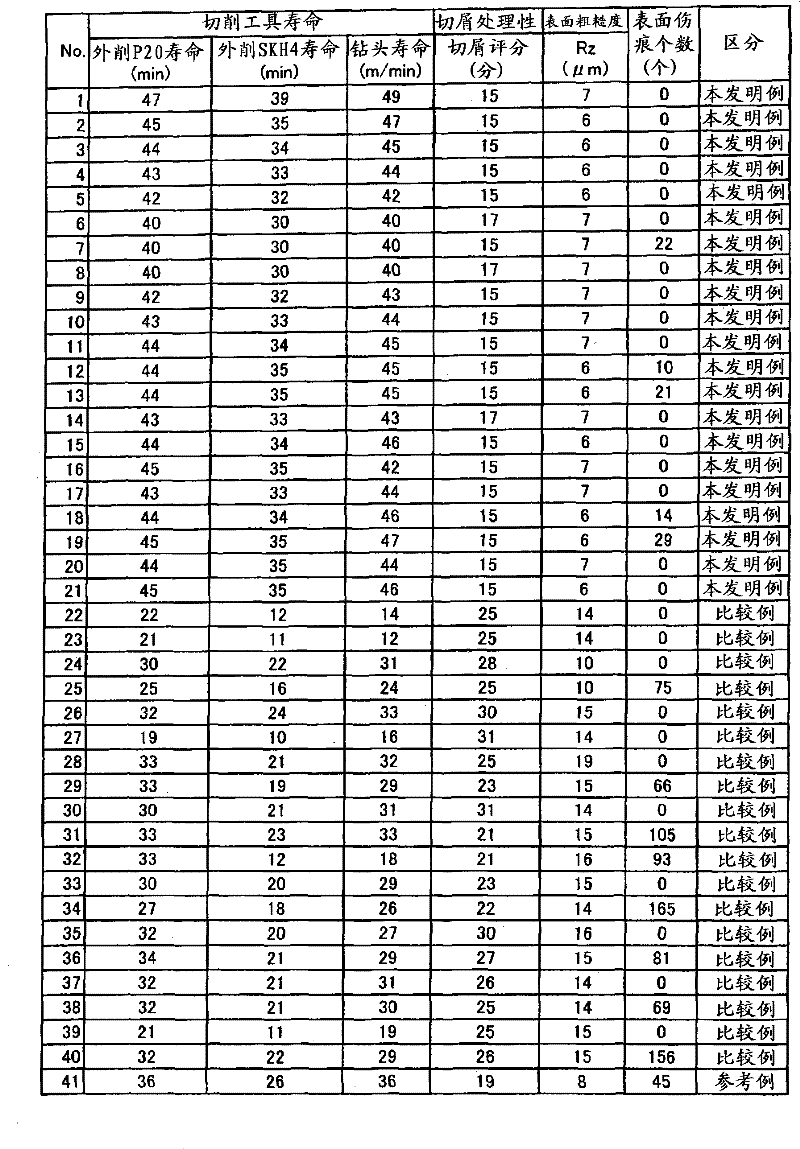

[0051] Examples of the present invention will be described below.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Login to View More

Abstract

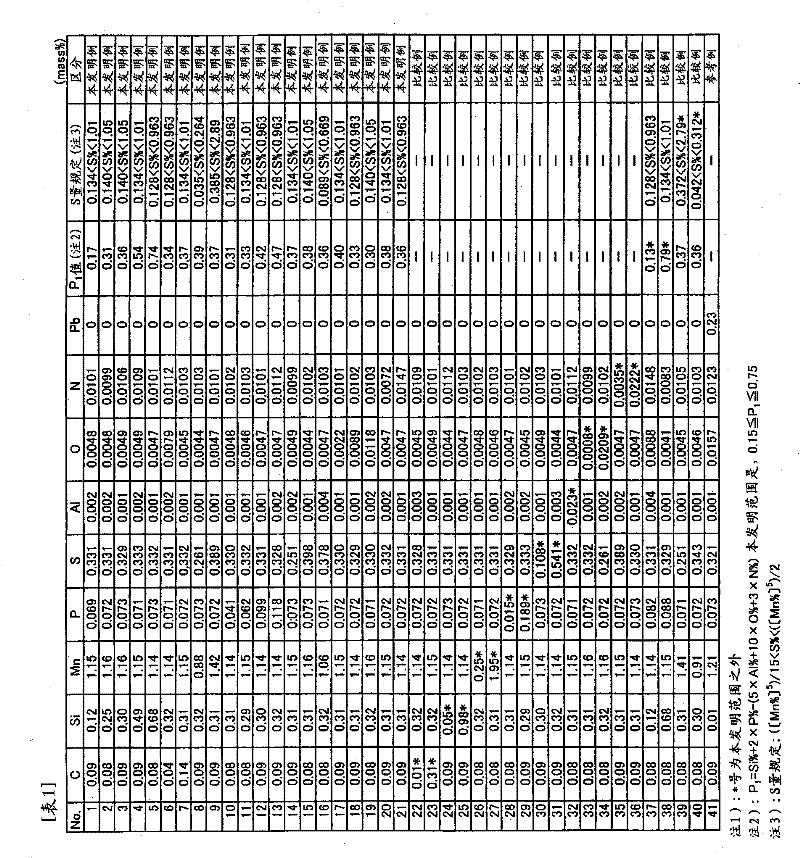

A low carbon sulphur free-cutting steel, in terms of mass%, is comprised of between 0.04-0.15% C, between 0.10-0.70% Si, between 0.85-1.50% Mn, between 0.040-0.120% P, between 0.250-0.400% S, less than 0.005% Al, between 0.0020-0.0120% O, between 0.0070-0.0150% N, with the remainder being Fe and unavoidable impurities; and which fulfills formula (1) and formula (2). 0.15% <= Si% + 2*P% - (5*Al% + 10*O% + 3*N%) <= 0.75% (1), ([Mn%]5) / 15 < S% < ([Mn%]5) / 2 (2).

Description

technical field [0001] The present invention relates to a low-carbon sulfur free-cutting steel containing elemental sulfur for improving machinability. Background technique [0002] In sulfur free cutting steel, a large amount of oxygen is contained in order to control the form of sulfide effective for machinability, that is, to perform spindle formation. However, since all the oxygen cannot be solid-dissolved in the sulfide, the formation of huge oxides cannot be avoided, so hairlines are formed and surface hairlines during hot rolling are caused by this. [0003] As a technique for solving this phenomenon, techniques for reducing the amount of oxygen or reducing the amount of Si as a deoxidizer to reduce the amount of oxides have been proposed (Patent Documents 1, 2, and 3). In addition, a technique of increasing solid-dissolved oxygen by increasing the amount of sulfide has also been proposed (Patent Document 4). [0004] Patent Document 1 relates to a free-cutting stee...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/60

CPCC22C38/02C22C38/001C22C38/06C22C38/04C22C38/60

Inventor 村上俊之富田邦和白神哲夫

Owner JFE BARS & SHAPES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com