A sorting machine for battery steel case

A technology of steel shell aligning machine and battery steel shell, which is applied to conveyors, conveyor objects, rotary conveyors, etc., can solve the problems of easy breakage of spring sheets, high maintenance costs, low arrangement efficiency, etc., and achieves easy processing and manufacturing. , low cost, improve the effect of finishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

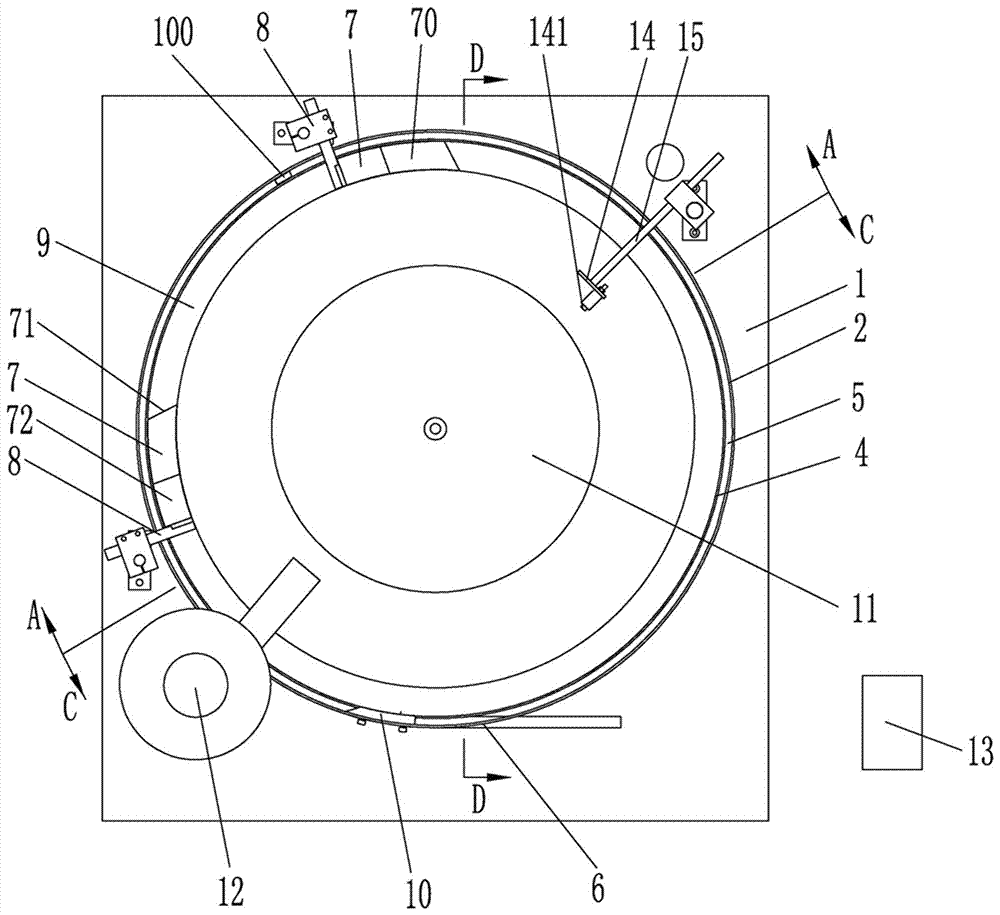

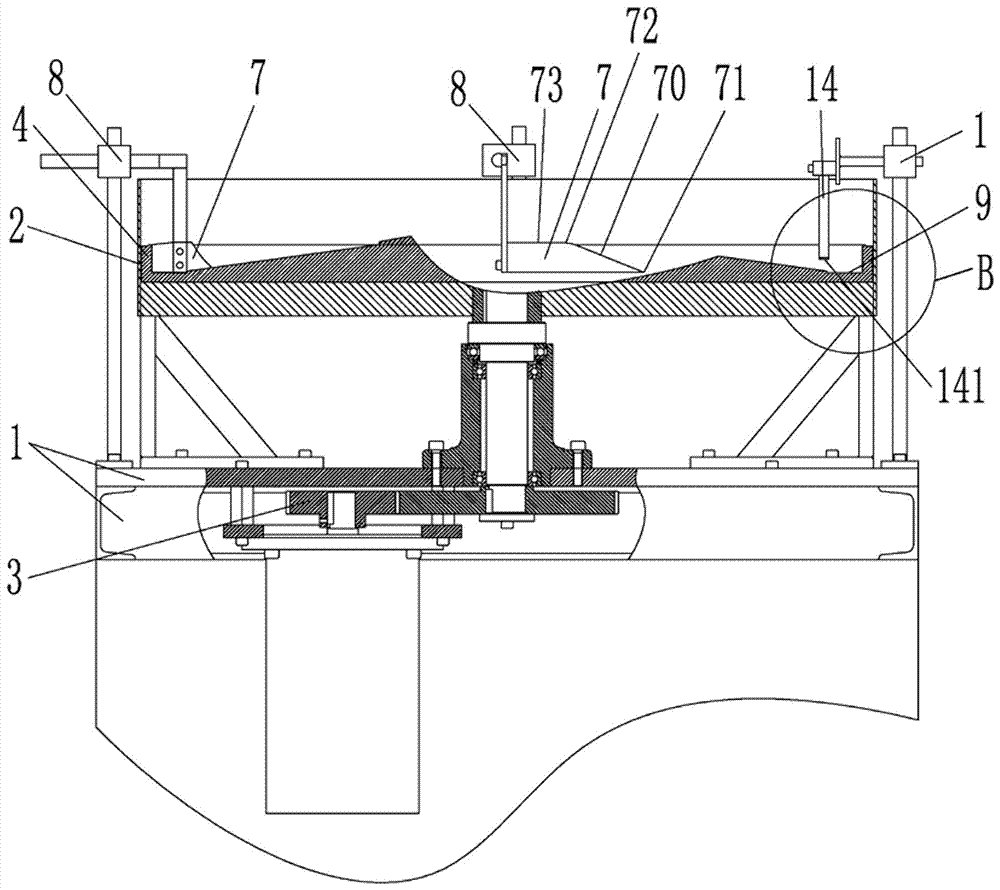

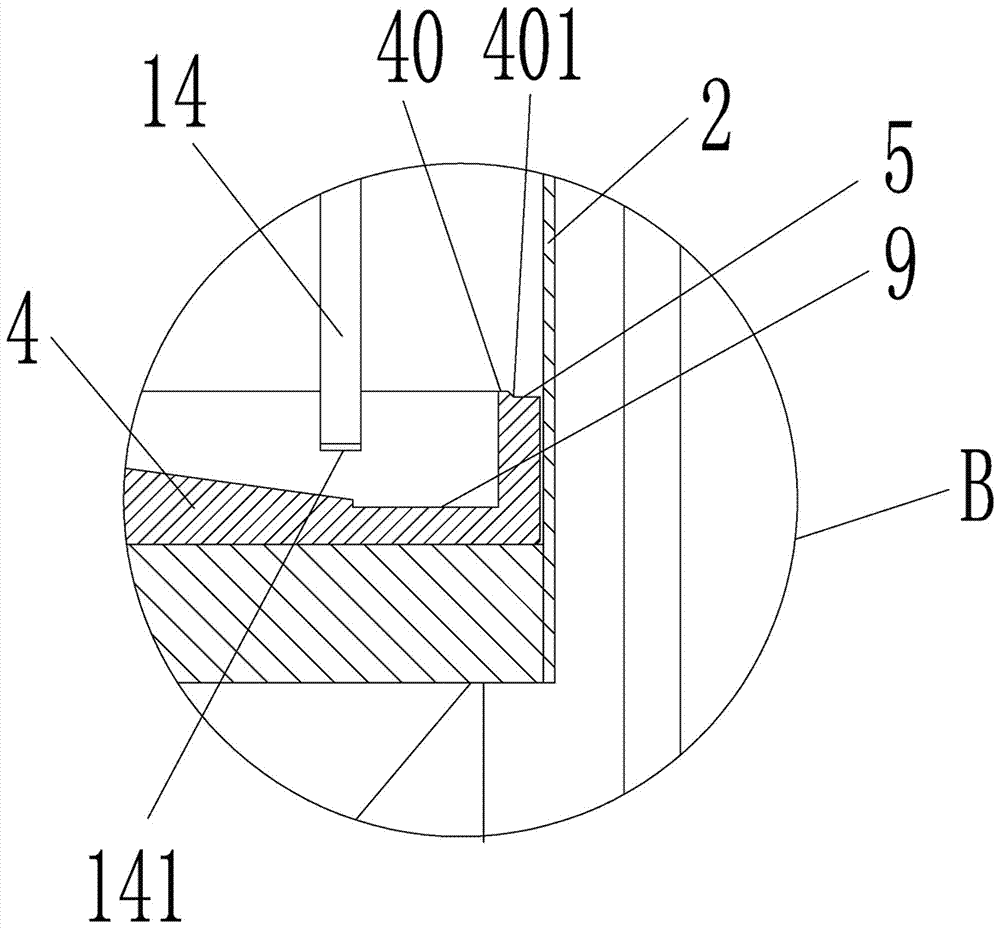

[0032] combine Figure 1~3 , a battery steel case 100 alignment machine, comprising a frame 1, an inner turntable 4 is arranged on the frame 1; a power unit 3 capable of driving the inner turntable 4 to rotate is installed on the frame 1 below the inner turntable 4; 4. The inner side wall is provided with a number of guides 7 at intervals. The guides 7 are connected to the inner turntable 4 without contact. 4 The distance of the inner surface is smaller than the thickness of the battery steel case 100, and the height of the highest position 72 of the slope 70 is not lower than the upper edge 40 of the inner turntable; the inner turntable 4 rotates relative to the guide device 7, and the direction of rotation is consistent with the direction of inclination of the slope 70; The upper edge 40 of the inner turntable is provided with a groove 5 along its circumference for placing only one battery steel case 100 ; the outer wall of the groove 5 is provided with a steel case outlet 6...

Embodiment 2

[0036] Different from Embodiment 1, the structure of the groove 5 is: the upper edge 40 of the inner turntable is directly provided with a groove 5 for placing a battery steel case 100 (such as Figure 4 shown). In this case, the outer disk 2 does not need to be provided, and the structure is simpler.

[0037] Such as figure 1 , 2 As shown, the guide device 7 is connected to the frame 1 through the support frame 8. At this time, the guide device 7 does not move, and the inner turntable 4 rotates relative to the guide device 7, and the direction of rotation is consistent with the inclination direction of the slope 70. Of course, the guide device 7 can also be directly fixed on the outer disk 2 .

[0038] When the guide device 7 and the inner turntable 4 rotate concentrically and in the same direction, the rotating speed of the guide device 7 is less than the speed of the inner turntable 4, and the inner turntable 4 rotates relative to the guide device 7, and the direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com