Polycrystalline diamond bit and manufacturing method thereof

A technology of polycrystalline diamond and drill bits, which is used in the manufacture of tools, twist drills, metal processing equipment, etc., can solve the problems of unsuitable processing or drilling, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

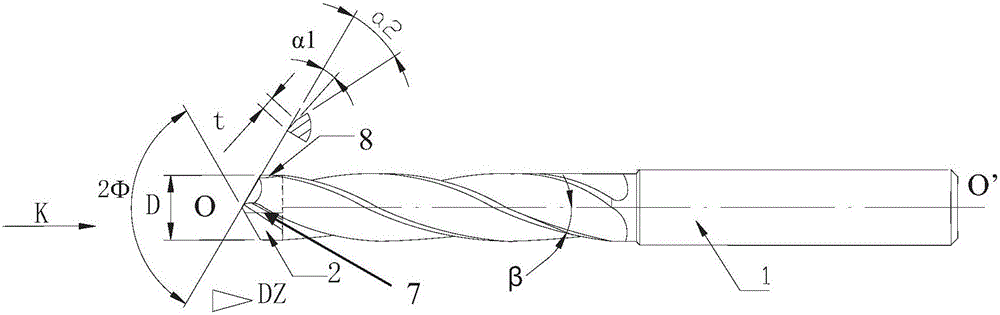

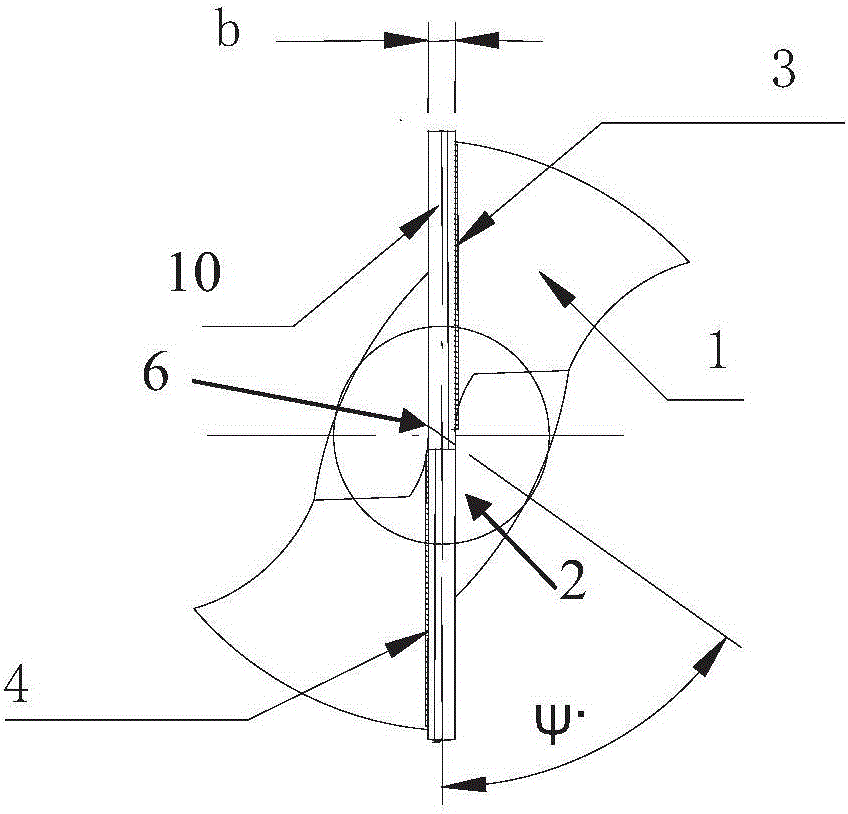

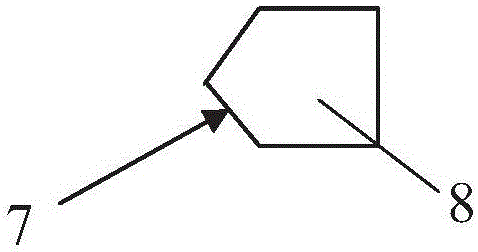

[0023] figure 1 Shown is a front view of one embodiment of a polycrystalline diamond (PCD) drill comprising a cemented carbide body 1 and an insert 2 secured to the end of the body, which in this embodiment consists of two pieces of PCD The composite sheets are spliced together, as detailed below. The drill bit defines a working rotary axis O-O', the cutter body 1 extends along the working rotary axis O-O' and the drill bit rotates around the working rotary axis O-O' during work, and at the same time figure 1 The axial feed is performed in the left direction as shown, so that the insert 2 (specifically, the cutting edge of the insert) is used as the cutting structure to drill a hole or form a required hole surface in the workpiece to be processed. As shown, the drill also defines a drill working diameter D that corresponds to the diameter of the corresponding hole formed in the workpiece being machined. Specifically, the working diameter D of the drill bit is defined by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com