Pile extracting clamp

A technology of pile clamps and fixtures, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, etc., can solve the problems of H-shaped steel piles such as cracking, breaking, poor stability, and large loss, so as to achieve small damage to piles and reduce The effect of concentrated stress and large force area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

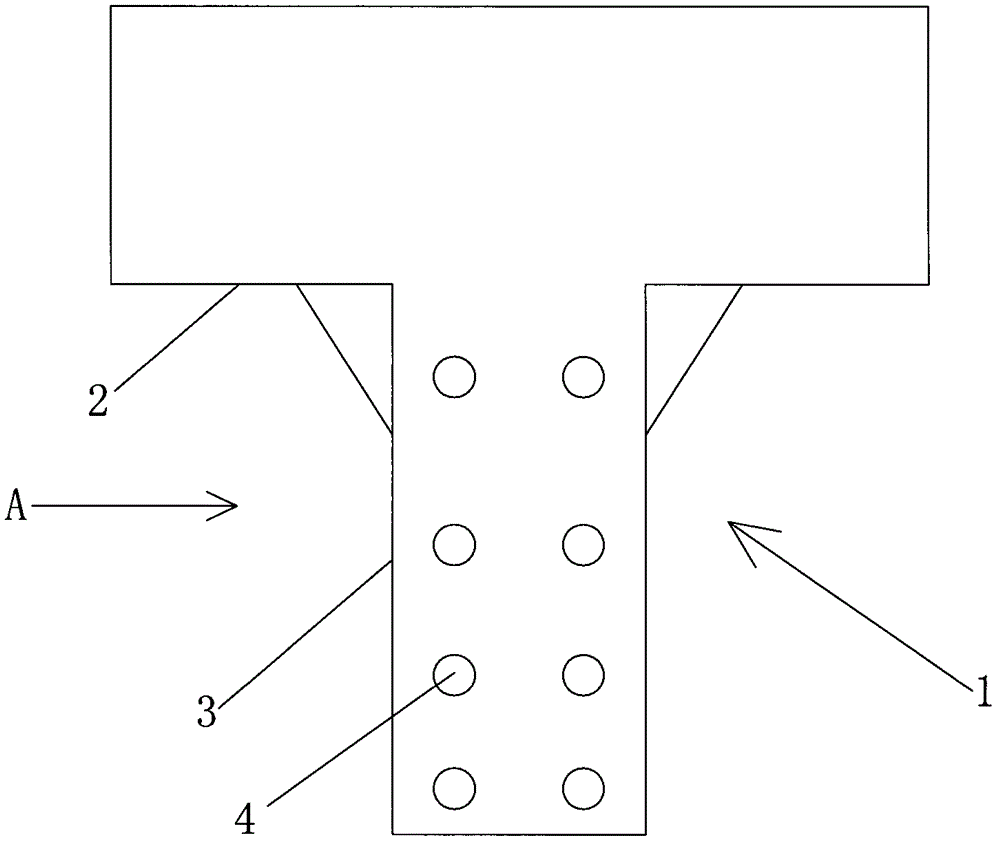

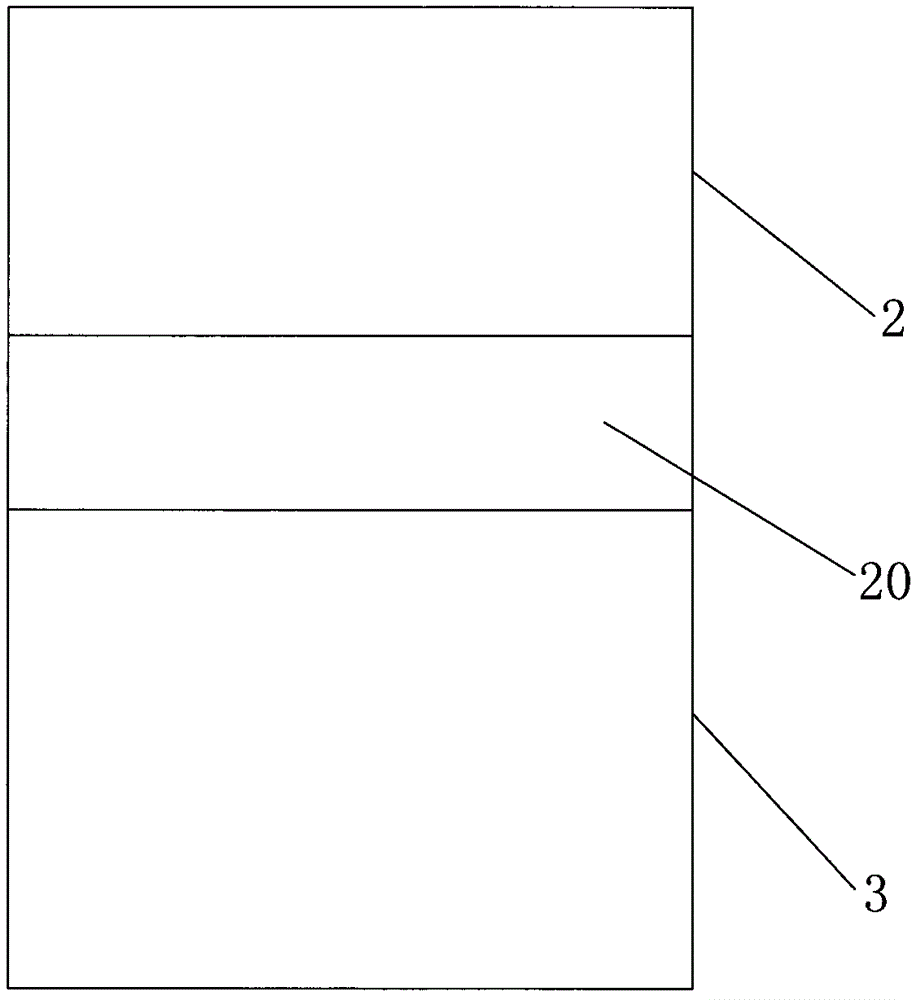

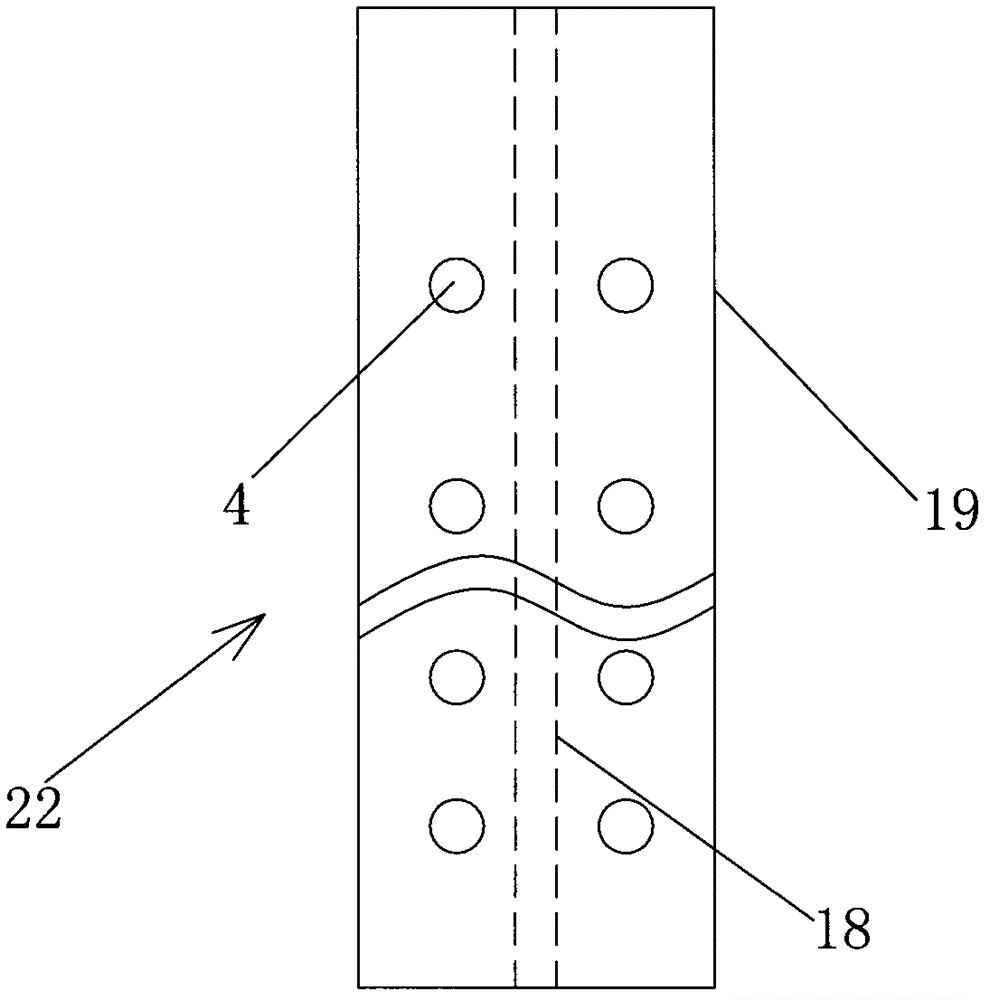

[0023] Embodiment: a kind of pile pulling fixture, as figure 1 , 2 As shown, the clamp 1 is T-shaped as a whole, and includes a horizontal hollow horizontal tube 2 and a vertical hollow vertical tube 3. The upper and lower ends of the hollow vertical tube 3 are open, and the upper end of the hollow vertical tube 3 is connected to the hollow The horizontal tube 2 is connected, and the front and rear side plates of the hollow vertical tube 3 are provided with rows of reserved holes 4 from top to bottom, for cooperating with the work of the clamp 1, such as image 3 As shown, the H-shaped steel pile 22 is composed of a web 18 and flange plates 19 on both sides of the web 18 , and a plurality of rows of reserved holes 4 are correspondingly provided on the flange plate 19 .

[0024] Such as Figure 4 As shown, in the left half section of the hollow transverse tube 2, a plurality of stiffening plates 7 parallel to each other for installing and fixing the horizontal movable chuck 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com