Shield machine with hobs with abrasion display function

A display function, shield machine technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problem that the shield machine does not have hob display function, etc., to achieve the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

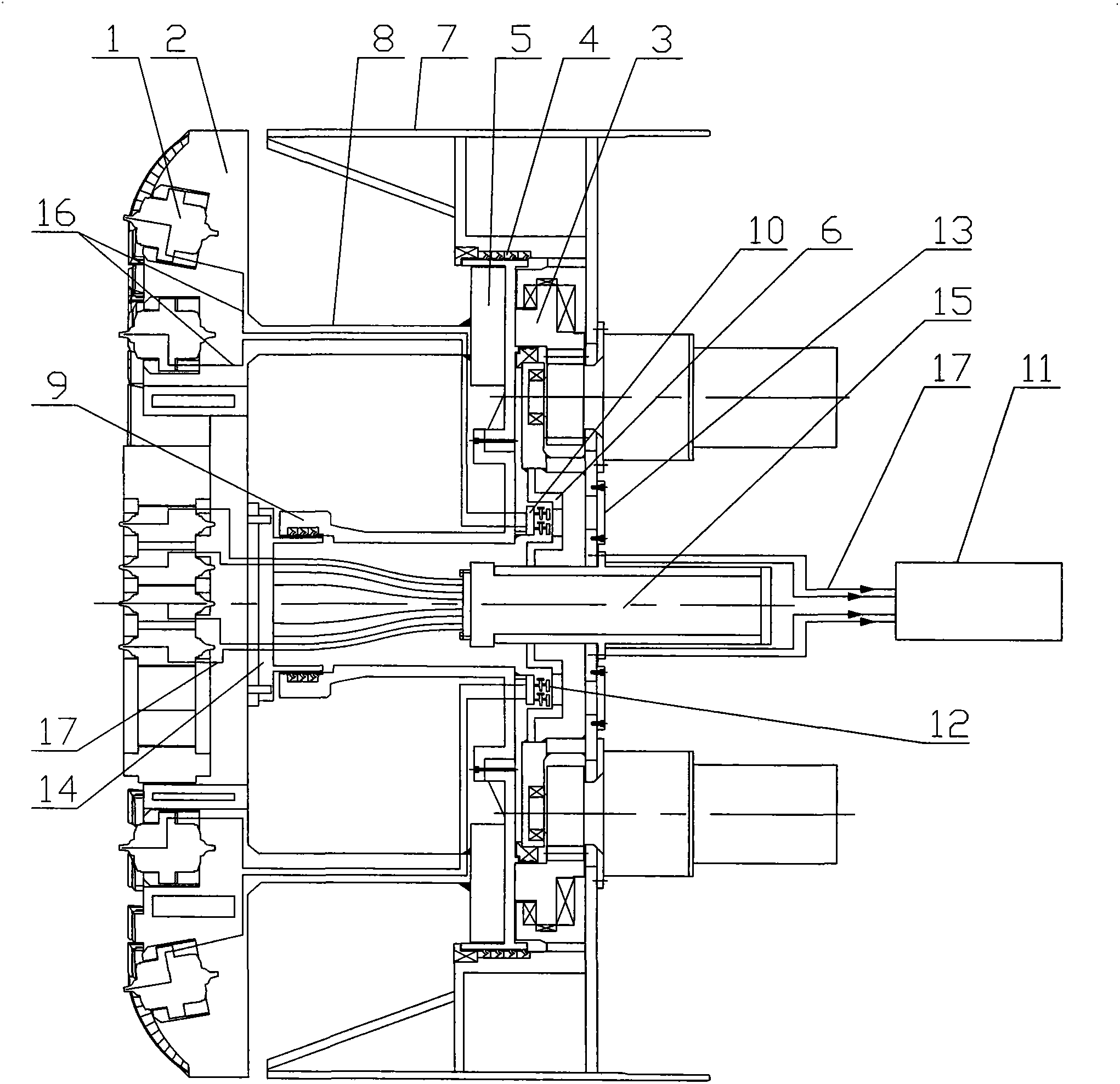

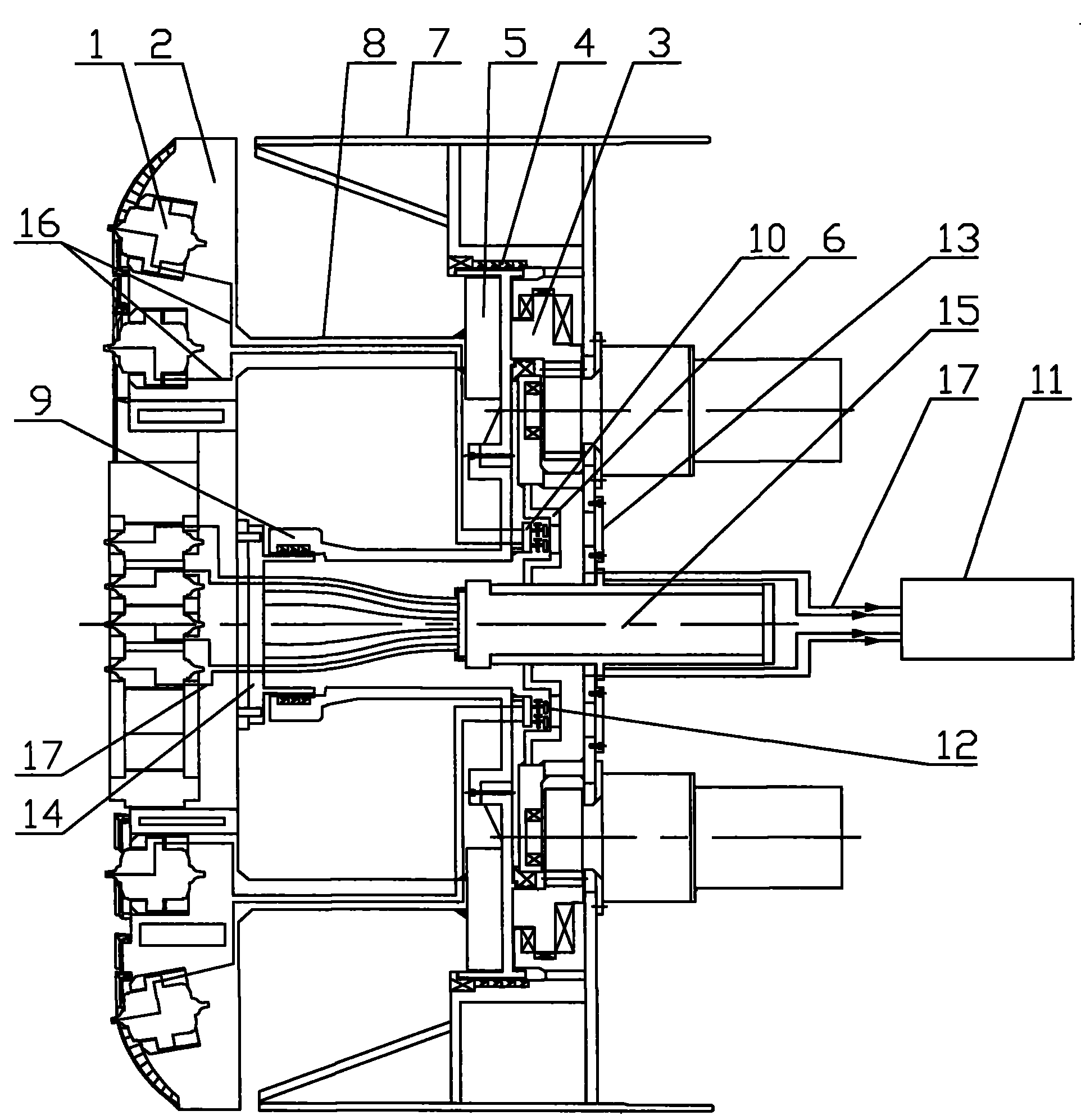

[0014] Such as figure 1 In the shown embodiment, the shield machine with hob wear display function according to the present invention includes a cutter head 2 equipped with several hobs 1 with wear indication function, main bearing 3, rotating sealing cover 4, rotating The front shield 7 of the bearing ring 5 and the fixed ring bracket 6, the rotating bracket 8 connecting the cutterhead 2 and the rotating bearing ring 5, the rotating sealing sleeve 9 connecting the cutterhead 2 and the rotating sealing cover 4, wherein the rotating bearing ring 5 and the rotating bracket 8 are welded as a whole, the rotating bearing ring 5 is connected with the rotating seal cover 4 and the main bearing 3 together by bolts, the front shield 7 is welded with the fixed ring bracket 6 as a whole, and each hob 1 with wear indicating function is provided with a cutter The end of the shaft communicates with the inner chamber of the blade, and the inner chambers are respectively connected to oil pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com