Special clamp for Rockwell hardometer measuring tool

A Rockwell hardness tester and special fixture technology, applied in the direction of measuring device, testing material hardness, strength characteristics, etc., can solve the problems of deformation and bending of internal lever mechanism, deviation of steel ball and measuring probe, distortion of hardness measurement data, etc. Guaranteed authenticity, guaranteed no deviation, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, all adopt equivalent replacement or equivalent transformation The technical solutions obtained by means of all methods fall within the protection scope of the present invention.

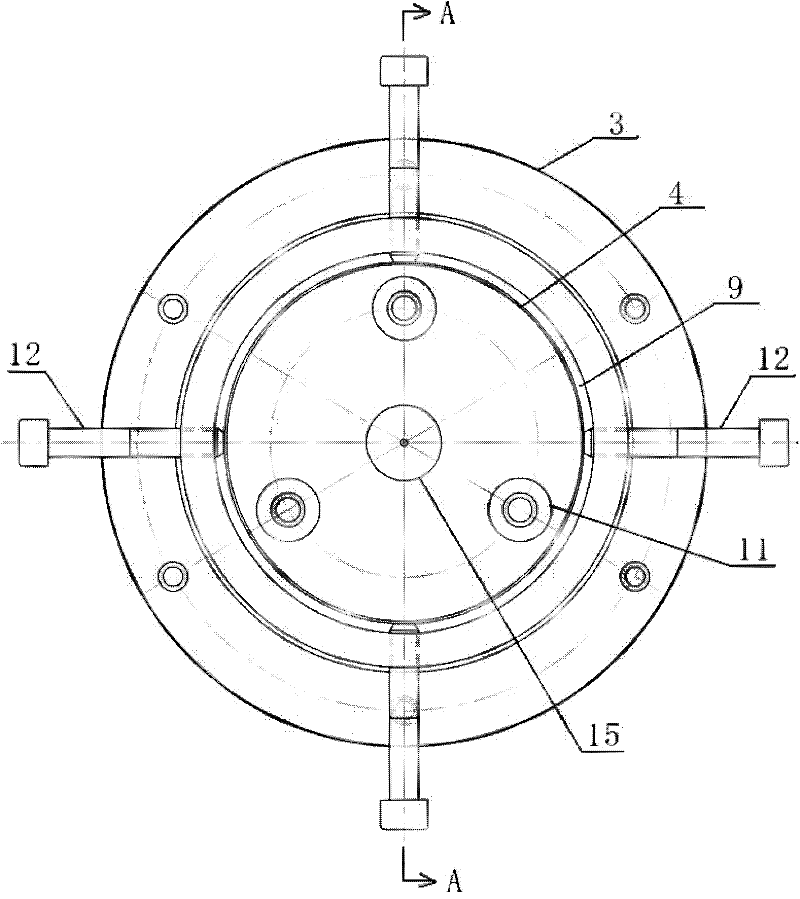

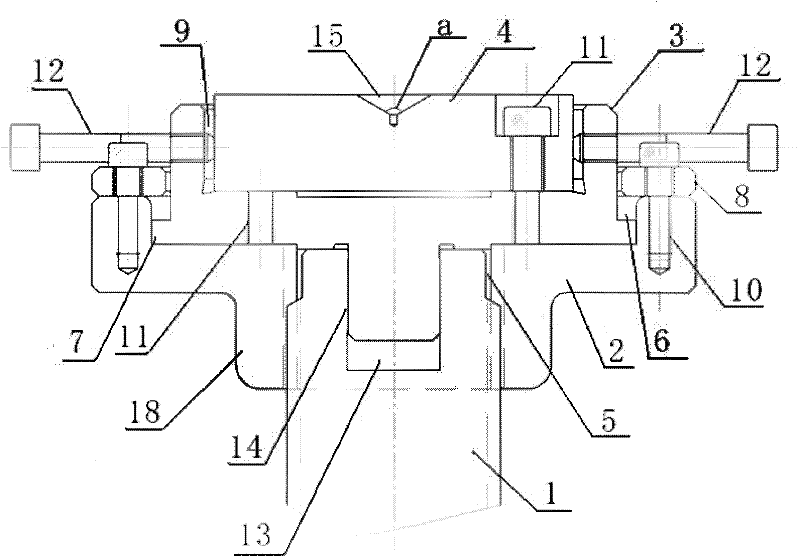

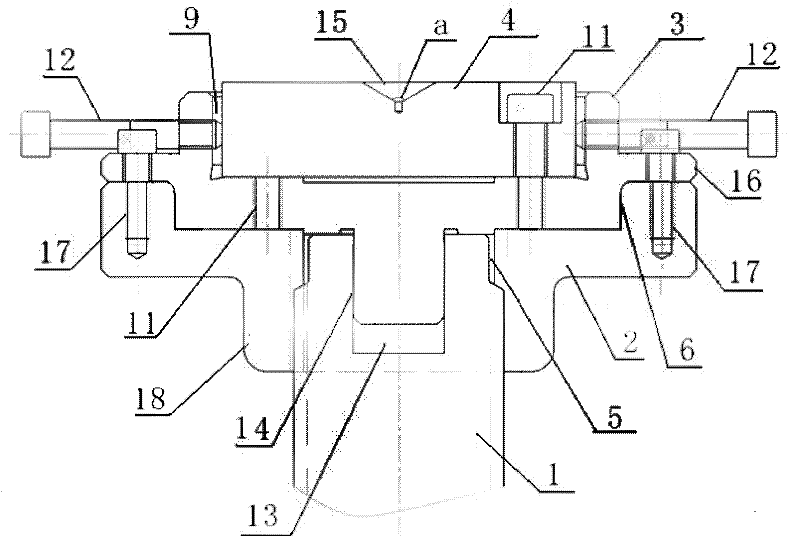

[0024] Such as figure 1 , 2 As shown in the figure, the labels in the figure represent the lifting rod 1, the mounting base 2, the platform fixing base 3, the cylindrical measuring workpiece platform 4, the mounting hole 5, the first groove 6, the limit seat 7, the locking ring 8, the second Groove 9, first screw 10, second screw 11, adjustment fixing screw 12, third groove 13, protrusion 14, tapered measuring groove 15, angle a of tapered groove, wherein, lifting rod 1, Both the mou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com