Method of making a composite device

A component and device technology, applied in the field of combined devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

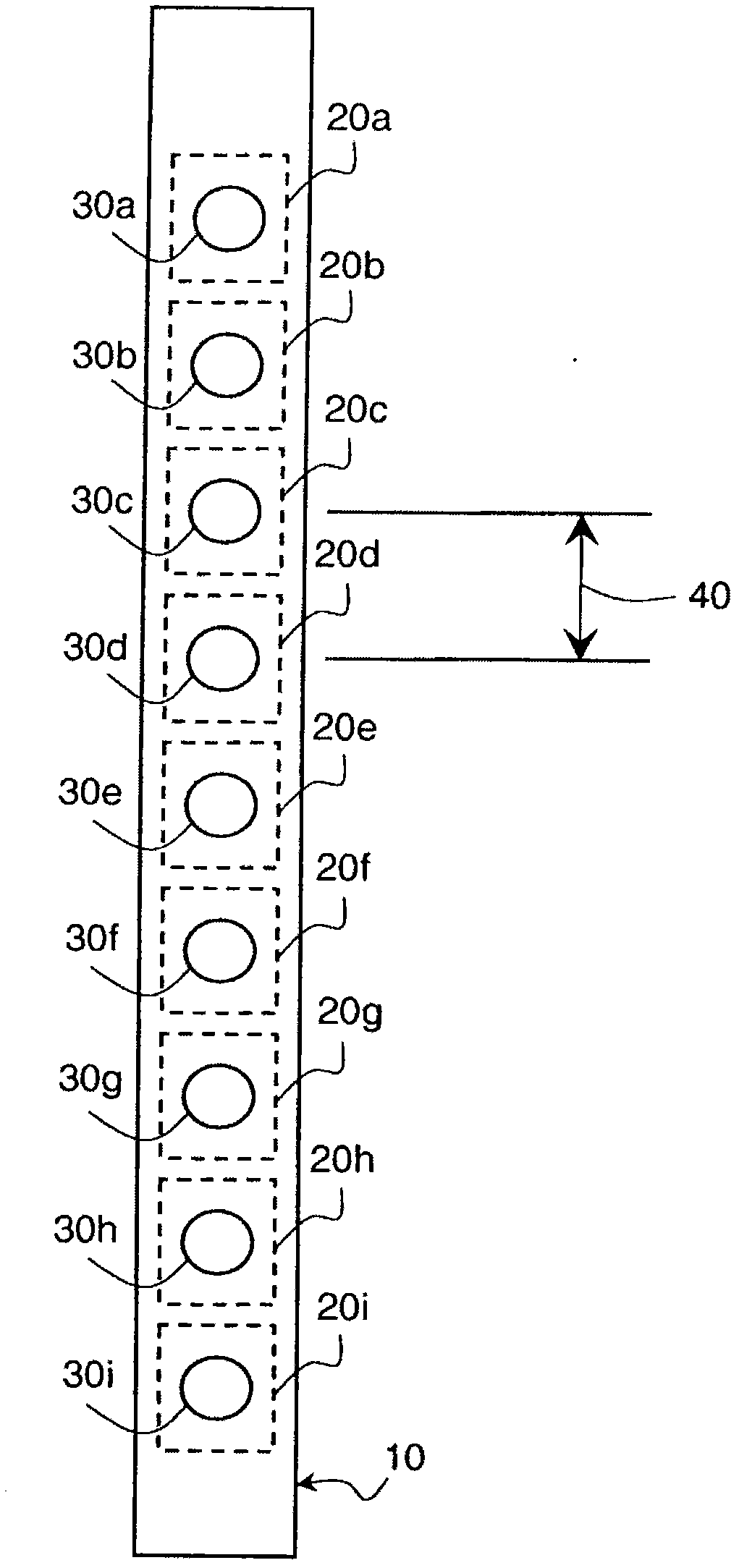

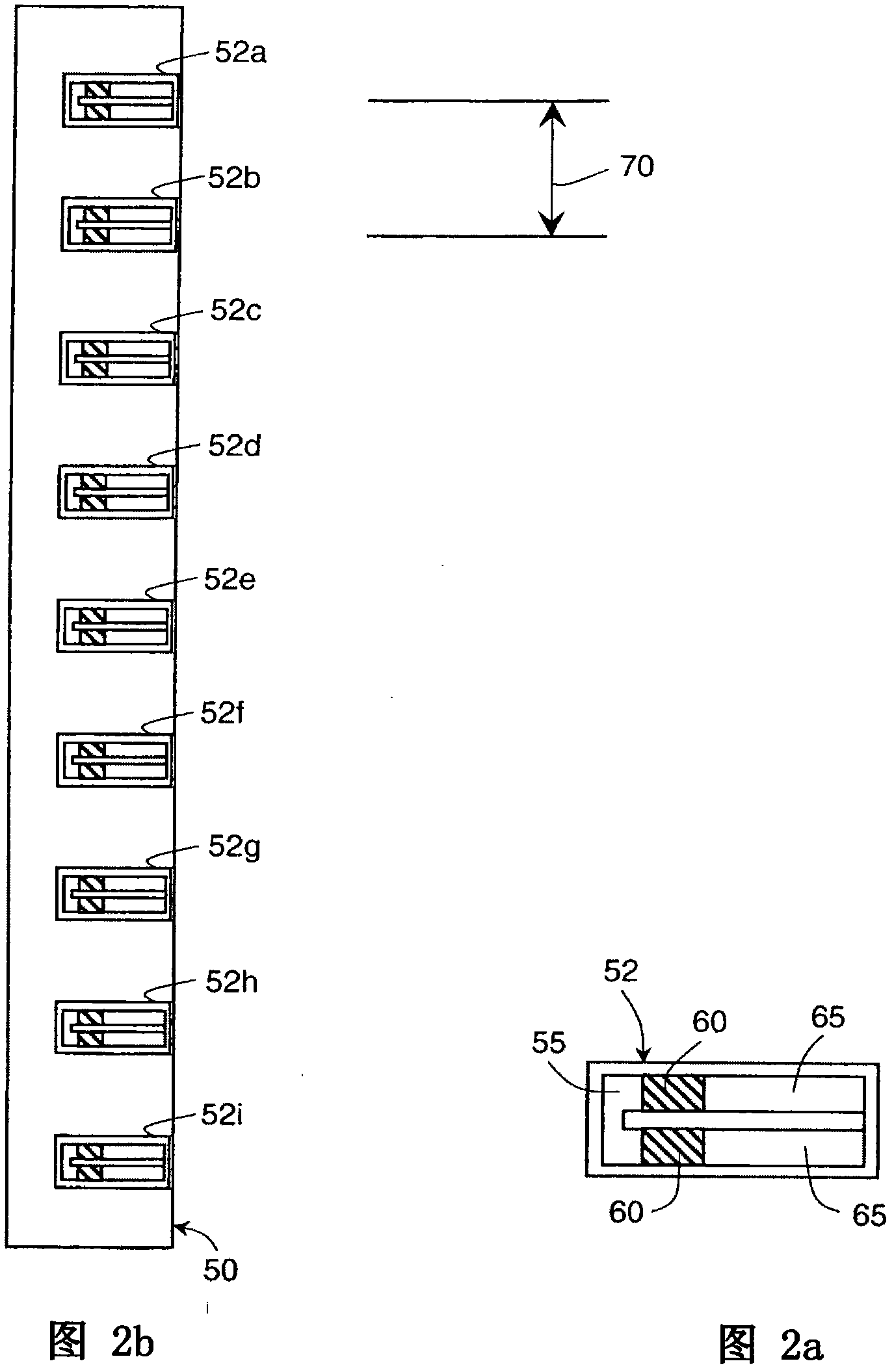

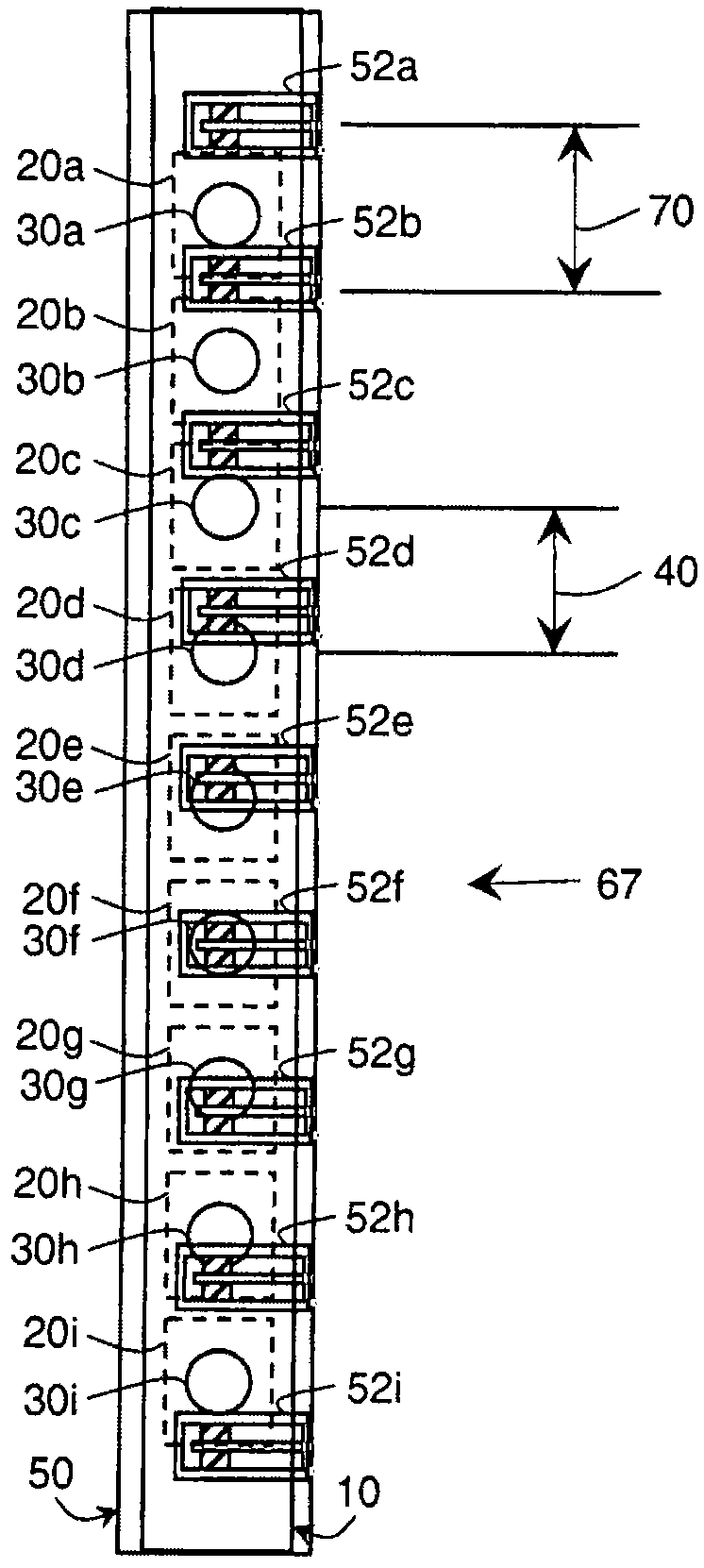

[0045]In general, there is a preferred alignment between two parts when they are secured together to make a composite device. In some cases, there are most and least preferred alignments and acceptable alignment ranges. With regard to the preferred alignment, the operation of the combined device is significantly improved. Operation was satisfactory with an acceptable alignment range. Finally, the operation is unsatisfactory for the least preferred alignments. More specifically, industry-known criteria will determine whether alignment yield is the most preferred outcome. Therefore, each type of combination device will have its own acceptance criteria.

[0046] A method for assembling a composite device is disclosed, comprising securing together two parts, where each part contains a set of components with a given spacing, the spacing between the components on the two parts being different. A subset of the combined components is then selected such that the tolerances between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com