Alarm method for indicating the wear of a tyre with a furrow

A tire and groove technology, applied in tire measurement, tire parts, tire tread/tread pattern, etc., can solve problems such as replacing tires too late, and achieve the effect of reducing implementation costs and easy processing algorithms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

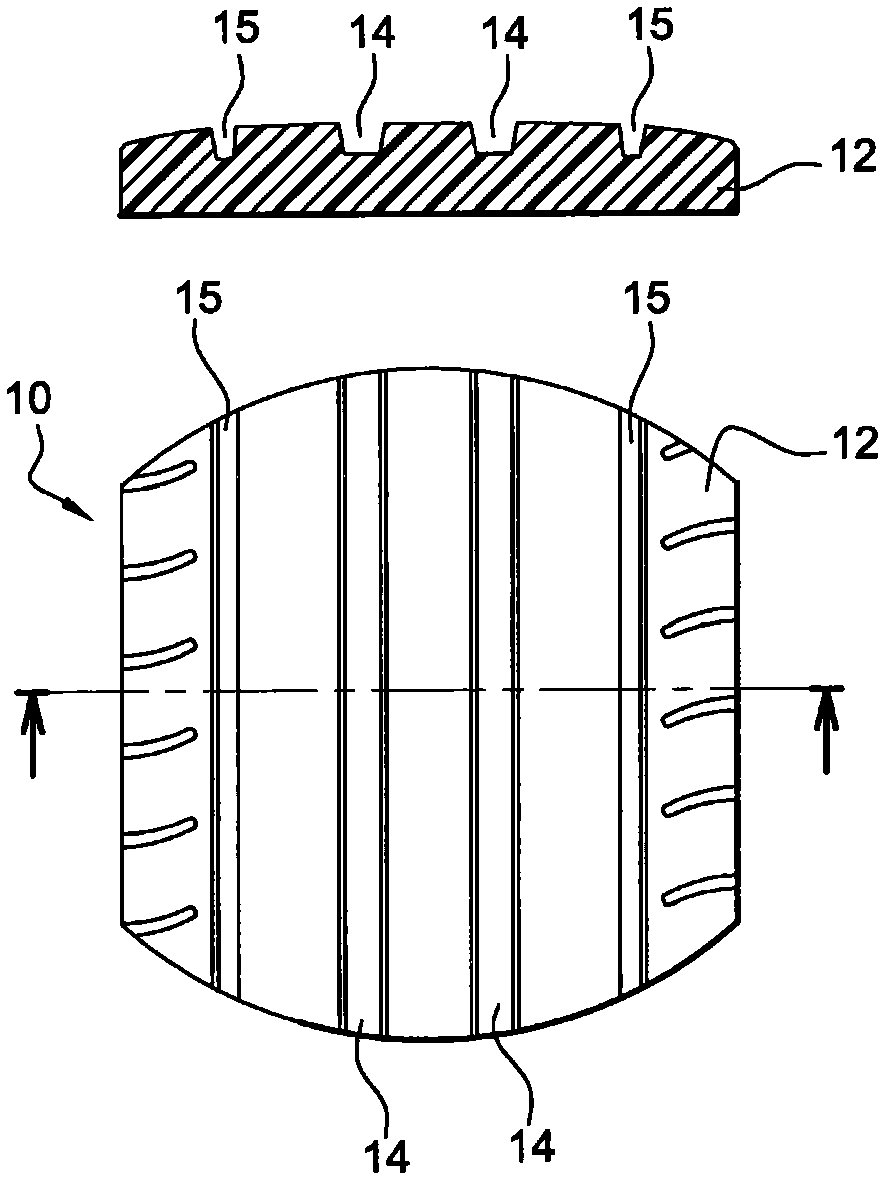

[0034] figure 1 The tire denoted by global reference numeral 10 according to the first embodiment is shown, and the tire 10 includes a tread strip 12.

[0035] The tread strip 12 includes two circumferential grooves 14 positioned near the midplane of the tire.

[0036] figure 1 The tire 10 shown in is in a new state, and the depth of the groove 14 in the middle of the tread strip is 8 mm. The tire 10 also includes two circumferential grooves 15, which are located in the shoulders, that is, near the longitudinal edges of the contact area of the tread strip 12.

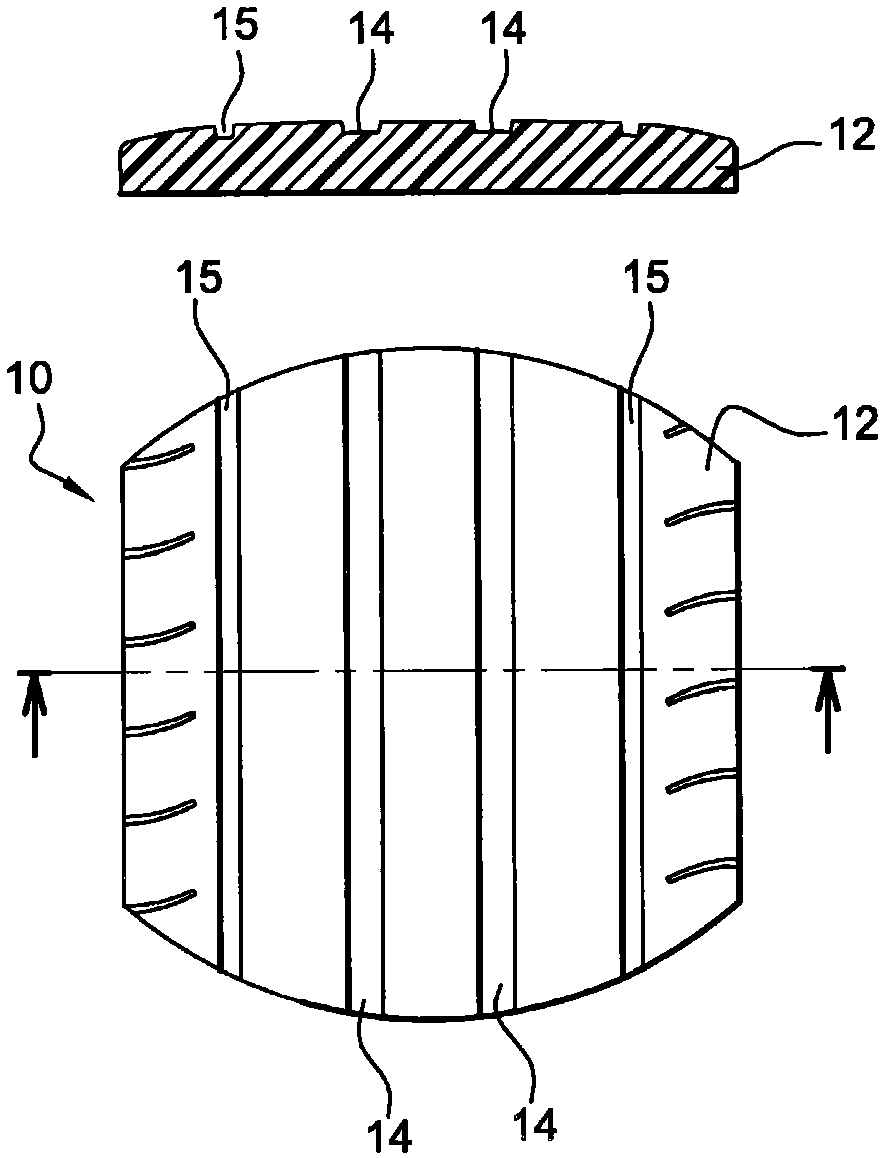

[0037] As the tire tread strip is gradually worn, the depth of the circumferential groove decreases. figure 2 Shows the state where the tread strip 12 is worn figure 1 In the tires. It can be noted that the depth of the circumferential grooves 14 and 15 is smaller than the depth of the grooves in the new tire. The depth in the worn state is, for example, equal to 2.5 mm.

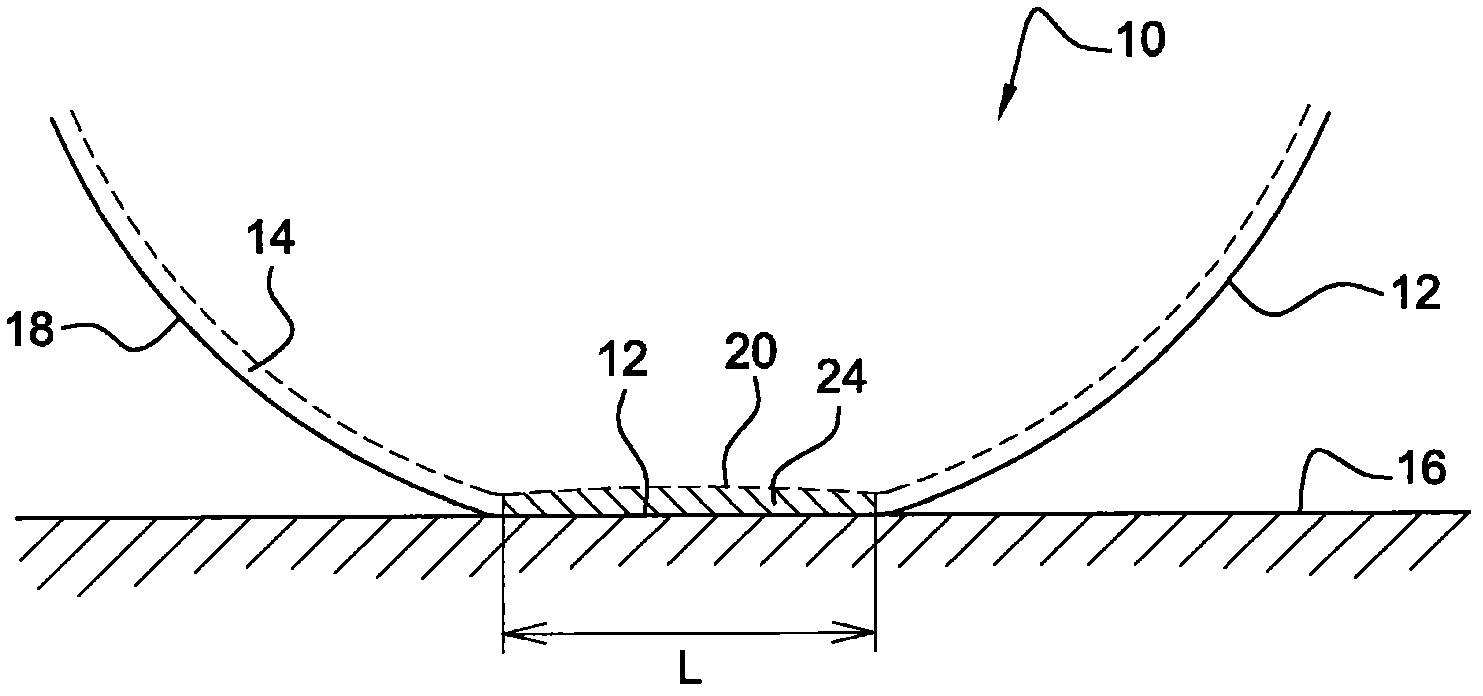

[0038] image 3 The tire 10 running along the grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com