Alarm method for indicating wear of tyre with furrow

A technology of tires and circumferential grooves, applied in tire measurement, tire parts, tire tread/tread pattern, etc., can solve the problem of late tire replacement, achieve the effect of reducing implementation cost and easy processing algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

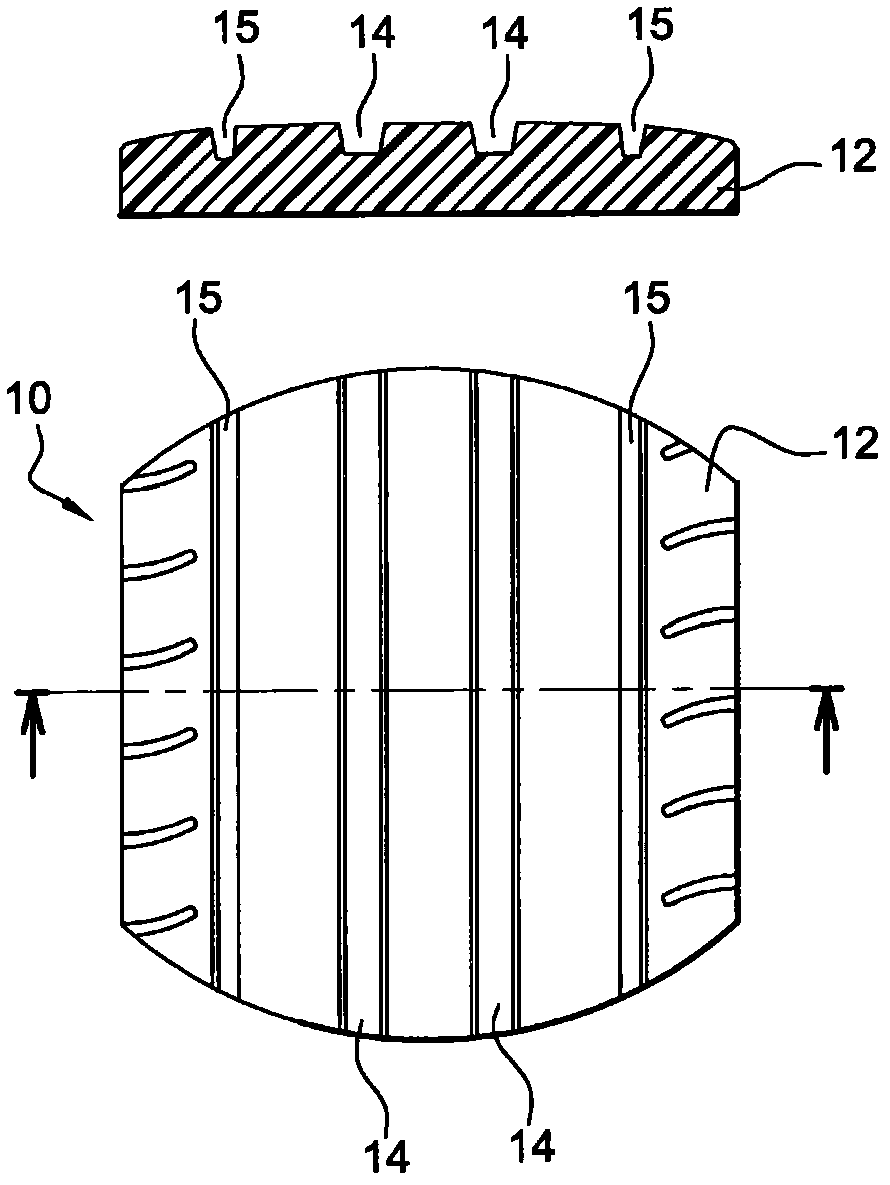

[0034] figure 1 A tire according to a first embodiment is shown generally indicated by 10 , comprising a tread strip 12 .

[0035] The tread strip 12 comprises two circumferential grooves 14 positioned near the mid-plane of the tyre.

[0036] figure 1 The tire 10 shown in is in a new condition and the groove 14 in the middle of the tread strip has a depth of 8 mm. The tire 10 also comprises two circumferential grooves 15 located in the shoulders, that is to say near the longitudinal edges of the contact area of the tread strip 12 .

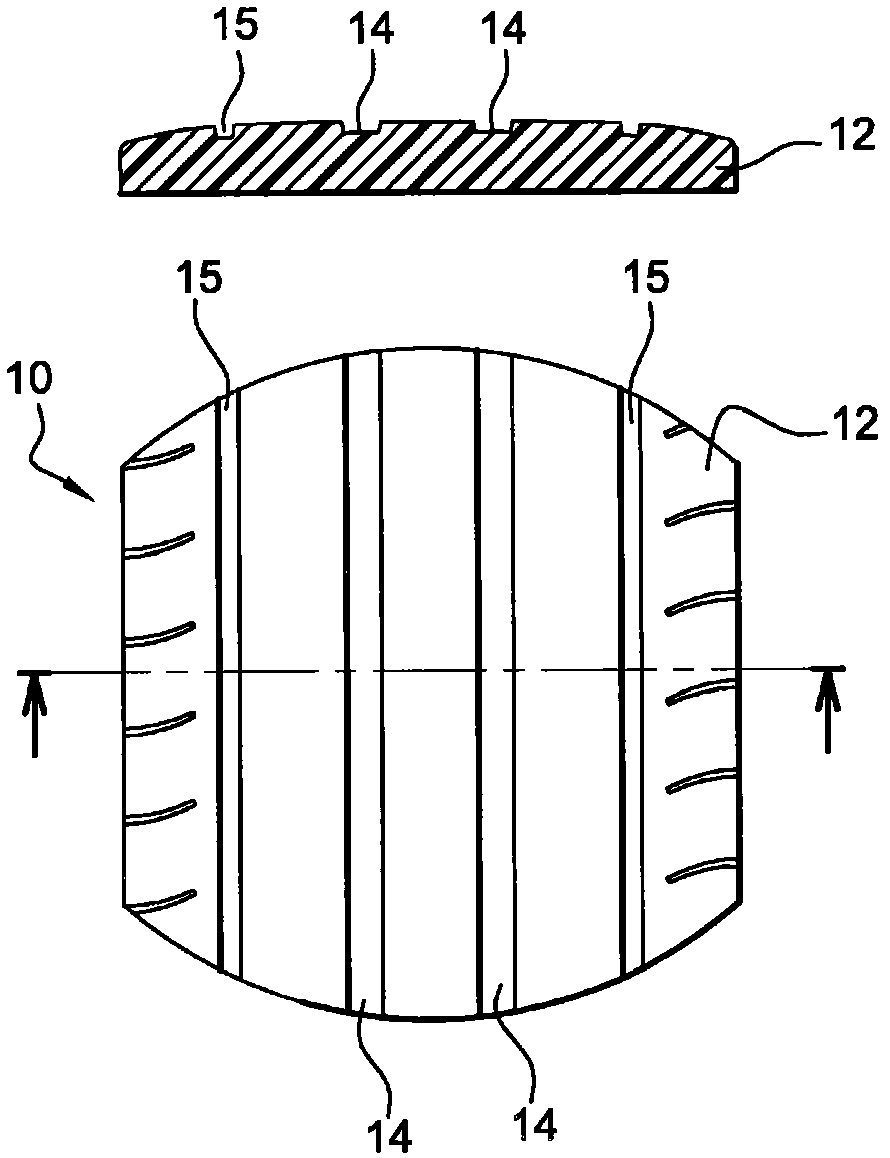

[0037] As the tire tread strip gradually wears, the depth of the circumferential grooves decreases. figure 2 shows the condition in which the tread strip 12 is worn figure 1 tires in. It can be noted that the depth of the circumferential grooves 14 and 15 is less than the depth of the grooves in a new tire. This depth in the worn state is equal to, for example, 2.5 mm.

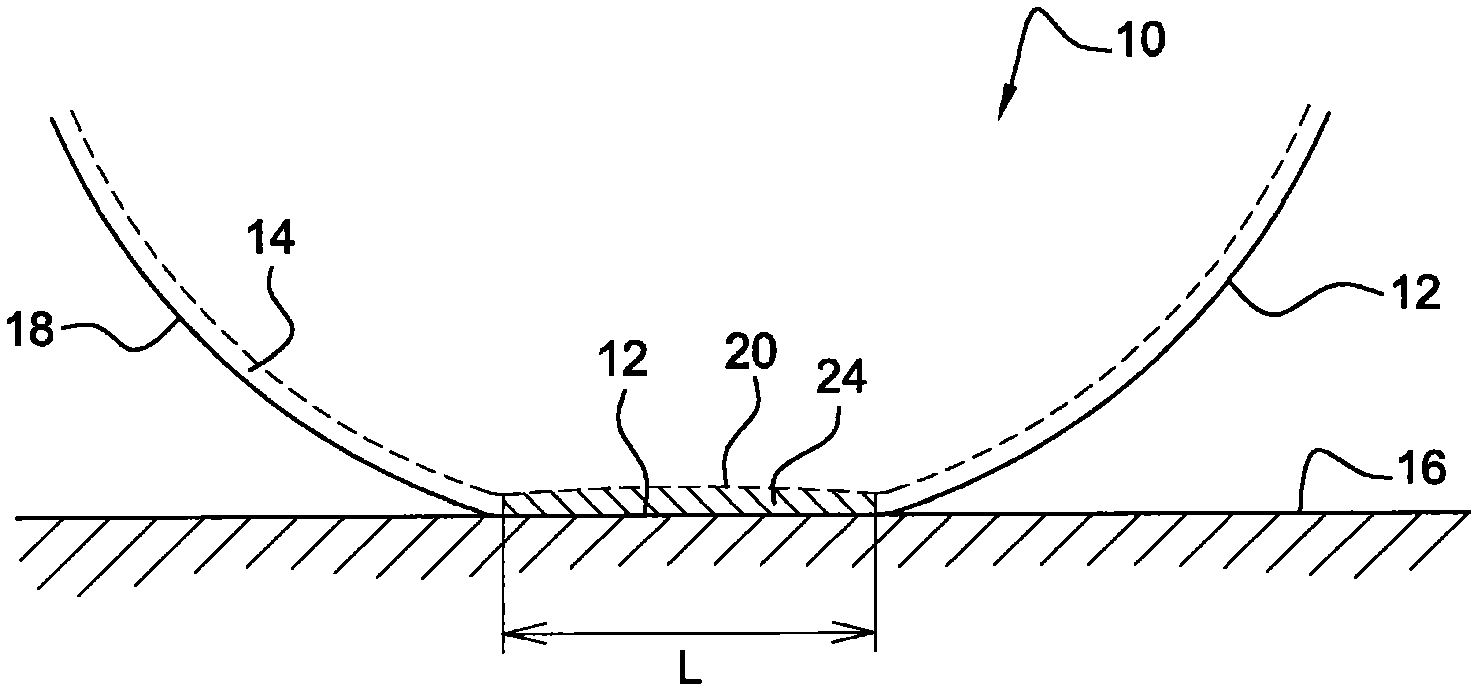

[0038] image 3The tire 10 is schematically shown running along a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com