Aircraft cabin panel for sound reduction

A technology for aircraft cockpits and panels, applied to aircraft parts, fuselage, weight reduction, etc., to achieve the effects of improving sound absorption characteristics, simplifying processing, and simplifying manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

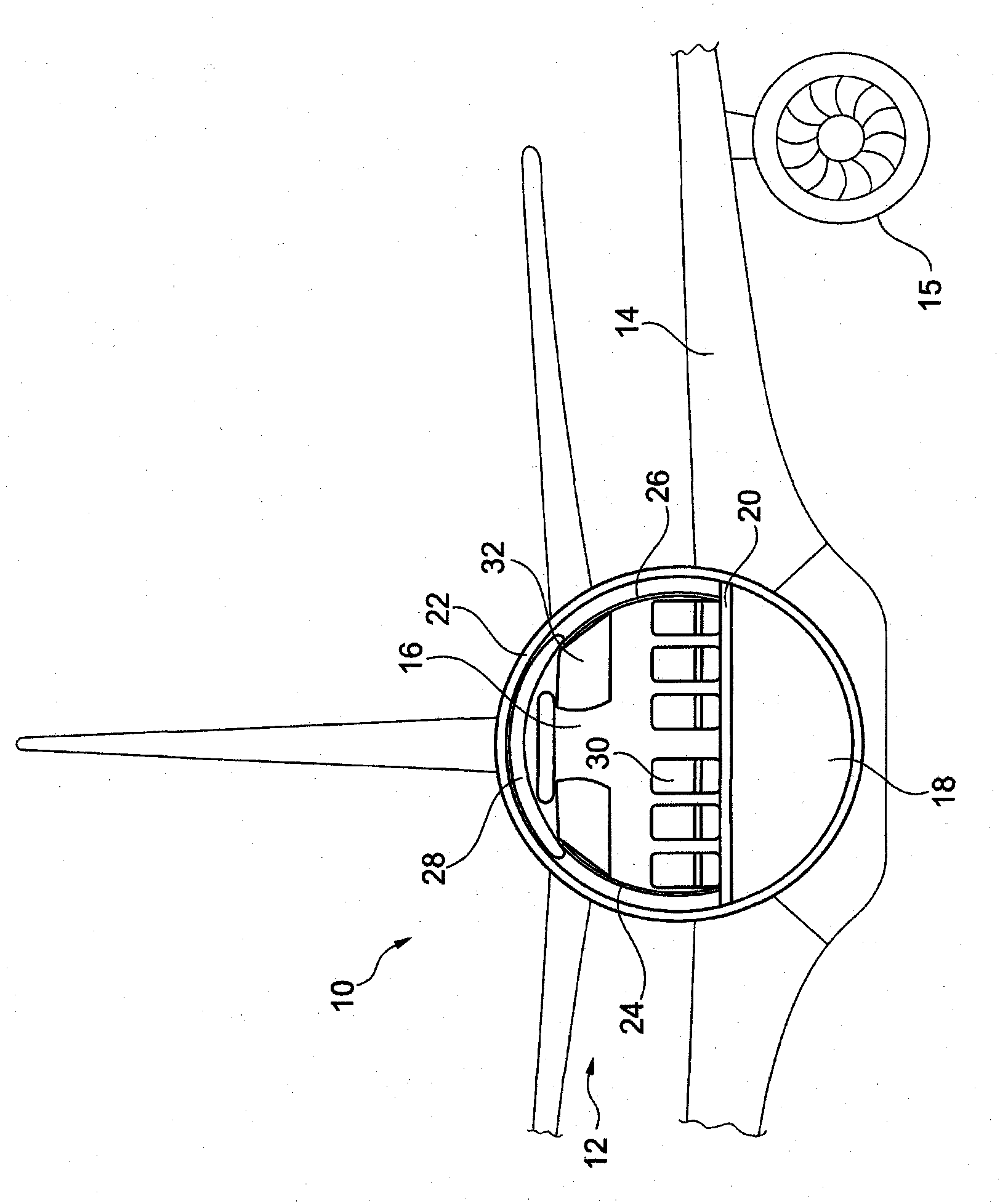

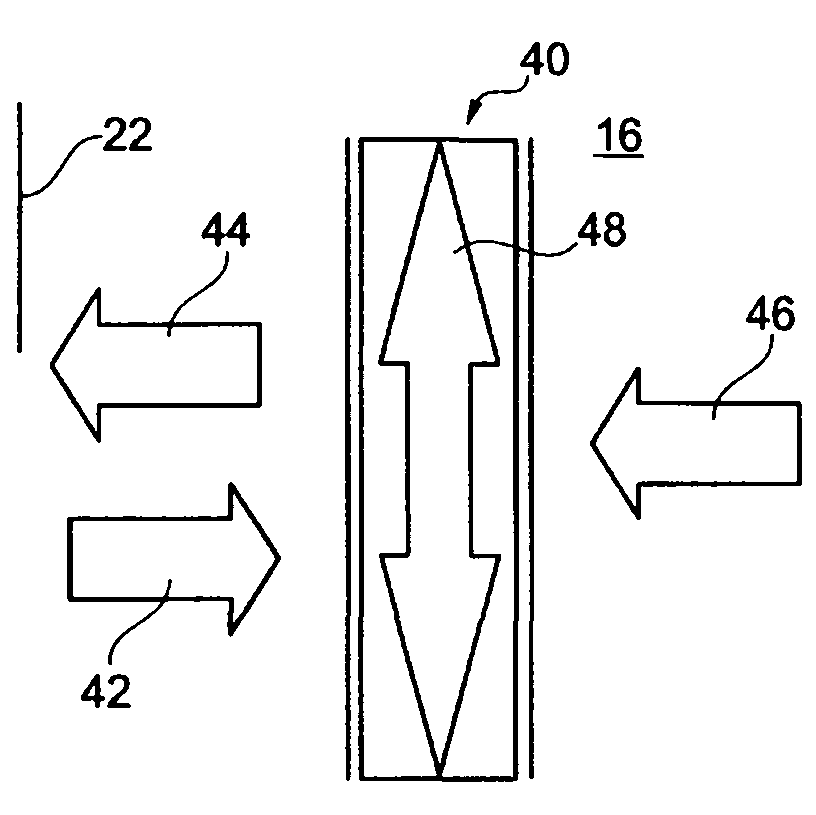

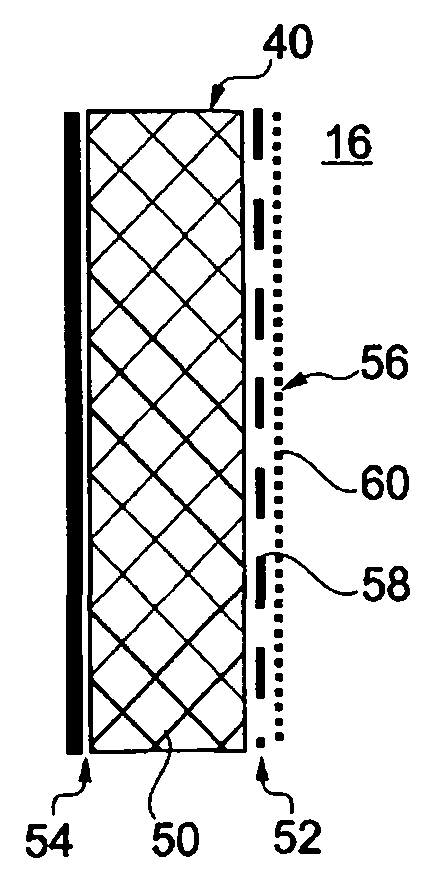

[0121] figure 1 An aircraft 10 is shown, which has a fuselage 12 and two wings 14 attached laterally to the fuselage, on which engines 15 are arranged. fuselage 12 in figure 1 It is shown in section transverse to its longitudinal axis. The fuselage 12 is divided by a horizontally extending floor 20 into an upper passenger cabin area 16 and a cargo area 18 arranged below the upper passenger cabin area. Furthermore, the fuselage 12 has a substantially surrounding outer aircraft skin 22 which is fastened to an aircraft fuselage structure (not shown in detail). In simple terms, the aircraft fuselage structure consists of a support structure consisting of bulkheads and stringers and ensures a stable design for absorbing external and internal loads.

[0122] In the cabin area 16 arranged above the floor 20 there are lateral cabin linings 24 , 26 along the outer wall 22 and a roof cabin lining 28 in the roof area.

[0123] The elements of the cabin lining 24 , 26 , 28 together wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com