Refuse transfer collection flip hopper compressor

A garbage transfer and flipping technology, which is applied in garbage collection, presses, garbage transmission, etc., can solve the problems of affecting the efficiency of the device, inconvenient feeding, complicated structure, etc., and achieves convenient feeding, high degree of automation, and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

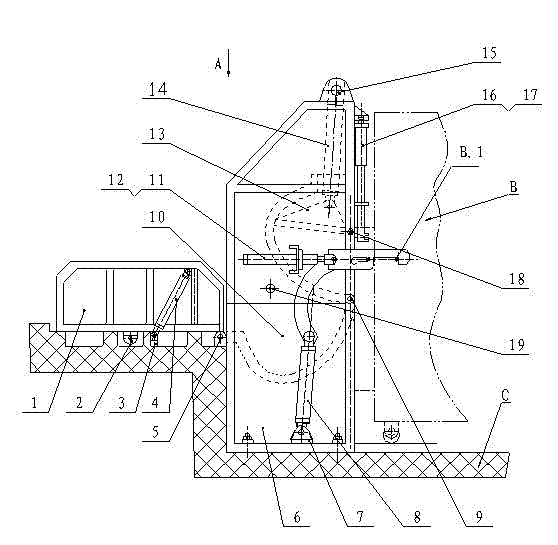

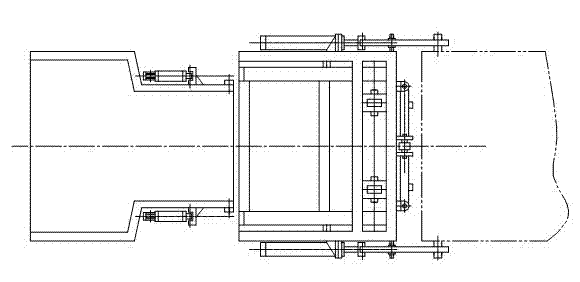

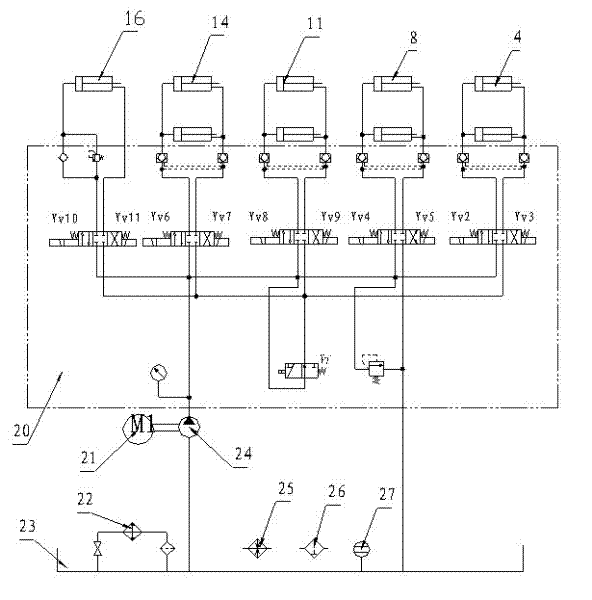

[0029] Referring to the accompanying drawings, the present invention relates to a garbage transfer collection flip-type hopper compressor, which mainly consists of a silo 1, a vibrator 2, a feed oil cylinder support 3, a feed oil cylinder 4, a hopper hinge support 5, and a frame 6. Overturn cylinder support 7, overturn cylinder 8, hopper hinge assembly 9, hopper 10, push-pull lock cylinder 11, push-pull lock device 12, pressure plate 13, pressure cylinder 14, pressure cylinder support 15, feed Door oil cylinder 16, feed door opening and closing device 17 and pressure plate hinge support assembly 18.

[0030] The feed cylinder support 3 is arranged on the foundation C, the feed cylinder 4 is installed on the feed cylinder support 3, and the piston rod end of the feed cylinder 4 is hinged to the feed bin 1;

[0031] The bin hinge support 5 is arranged on the foundation C, and the bin 1 is hinged on the bin hinge support 5;

[0032] The vibrator 2 is arranged on the feed bin 1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com