Tool cutting edge wear detection fixture

A technology for detecting fixtures and cutting edges, which is applied to measuring devices, testing wear resistance, instruments, etc., can solve problems such as difficult accurate positioning and clamping, poor versatility, and complex structure, and achieves convenient positioning and clamping, compact structure, The effect of simple fixture structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

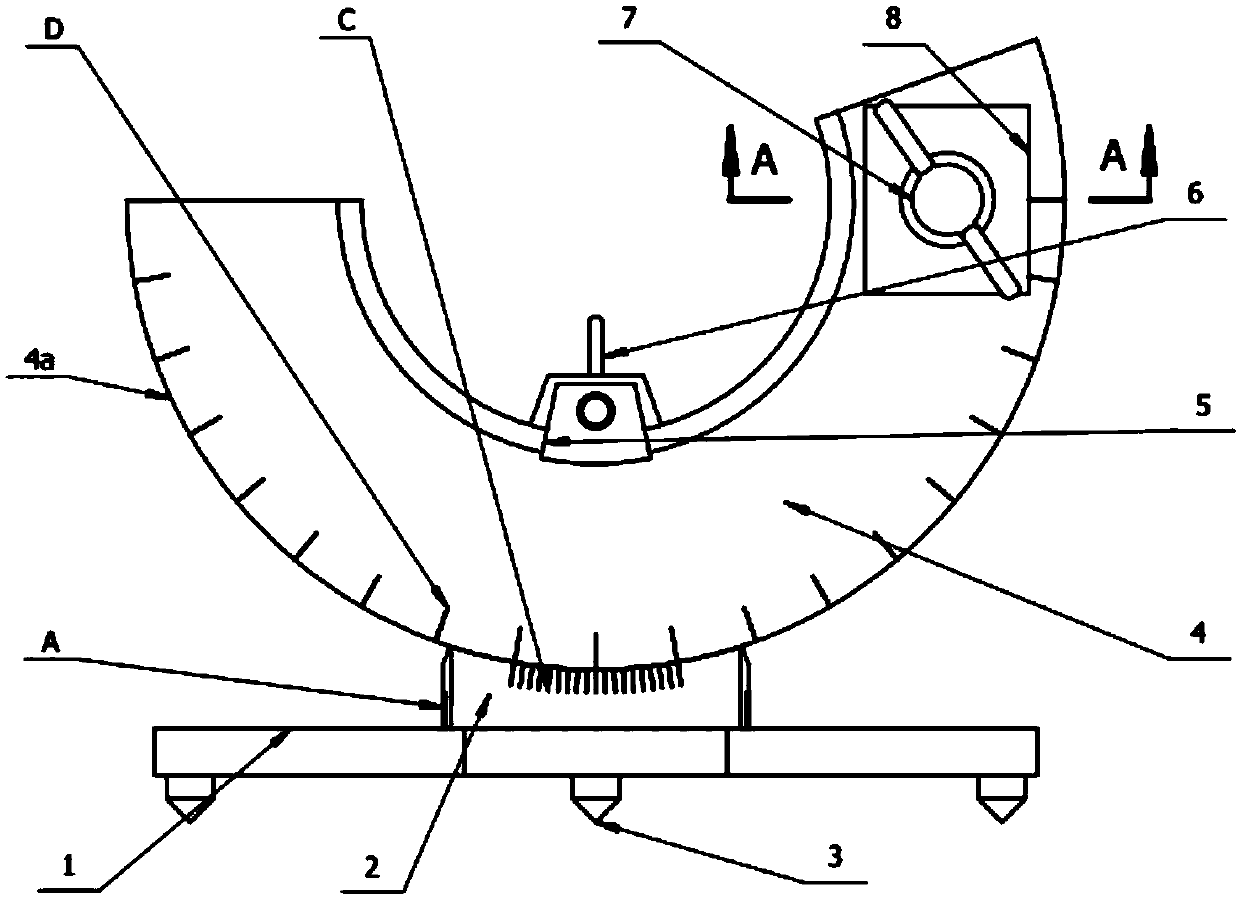

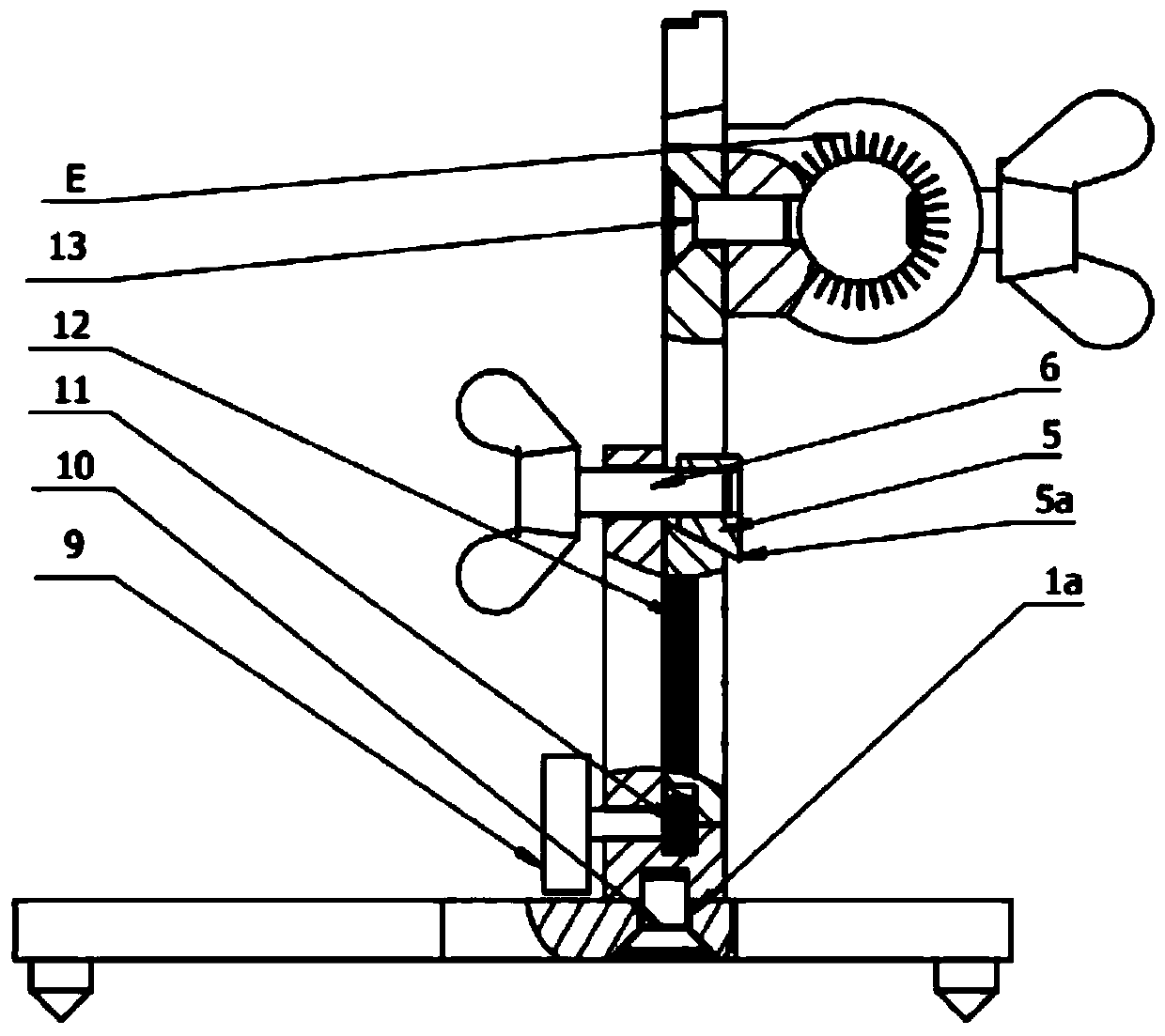

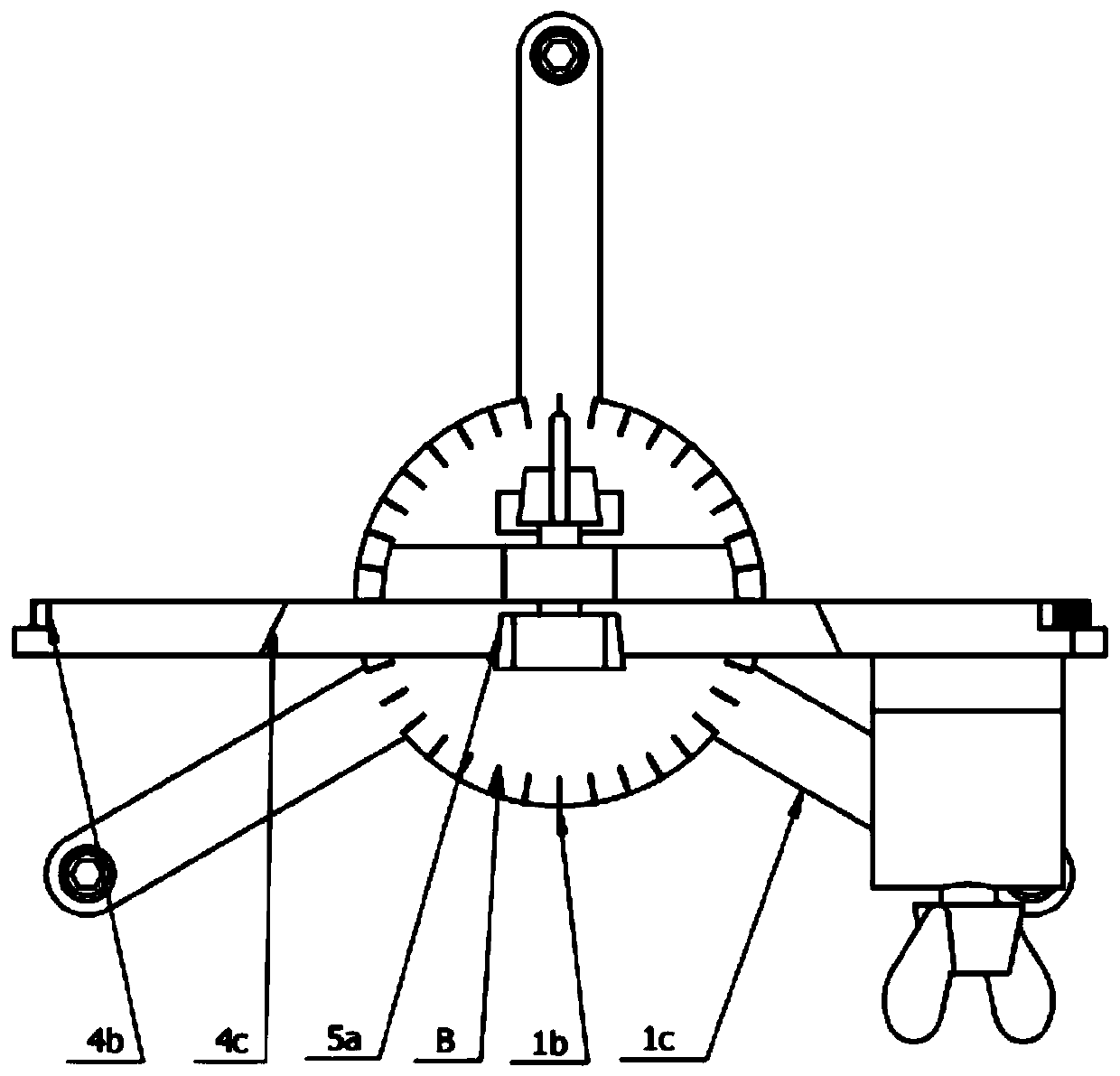

[0015] The concrete implementation of the present invention is described in detail below in conjunction with accompanying drawing and technical scheme:

[0016] In the embodiment, the fixture is composed of a base, a bracket, an indexing plate, a gear assembly, a pressing assembly, and a cartridge assembly; the set of engraved lines for accurately indicating the circumferential rotation angle of the mechanism is engraved on the fixture, and the pitch angle of the tool is also engraved. Accurate positioning of the degree, the set of marking lines indicating the pitch angle of the indexing plate and the marking line of the chuck angle for positioning the knife with the accurate reading of the tool handle mark. The fixture has three rotational degrees of freedom and is a tool inspection fixture with scale indication and fastening functions, which can realize rapid and accurate positioning, locking and inspection of the tool, and improves the inspection efficiency and accuracy.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com