Suction hood

The technology of a suction hood and a suction device, which is applied in the field of suction hoods, can solve problems such as low efficiency and achieve the effect of improving suction characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

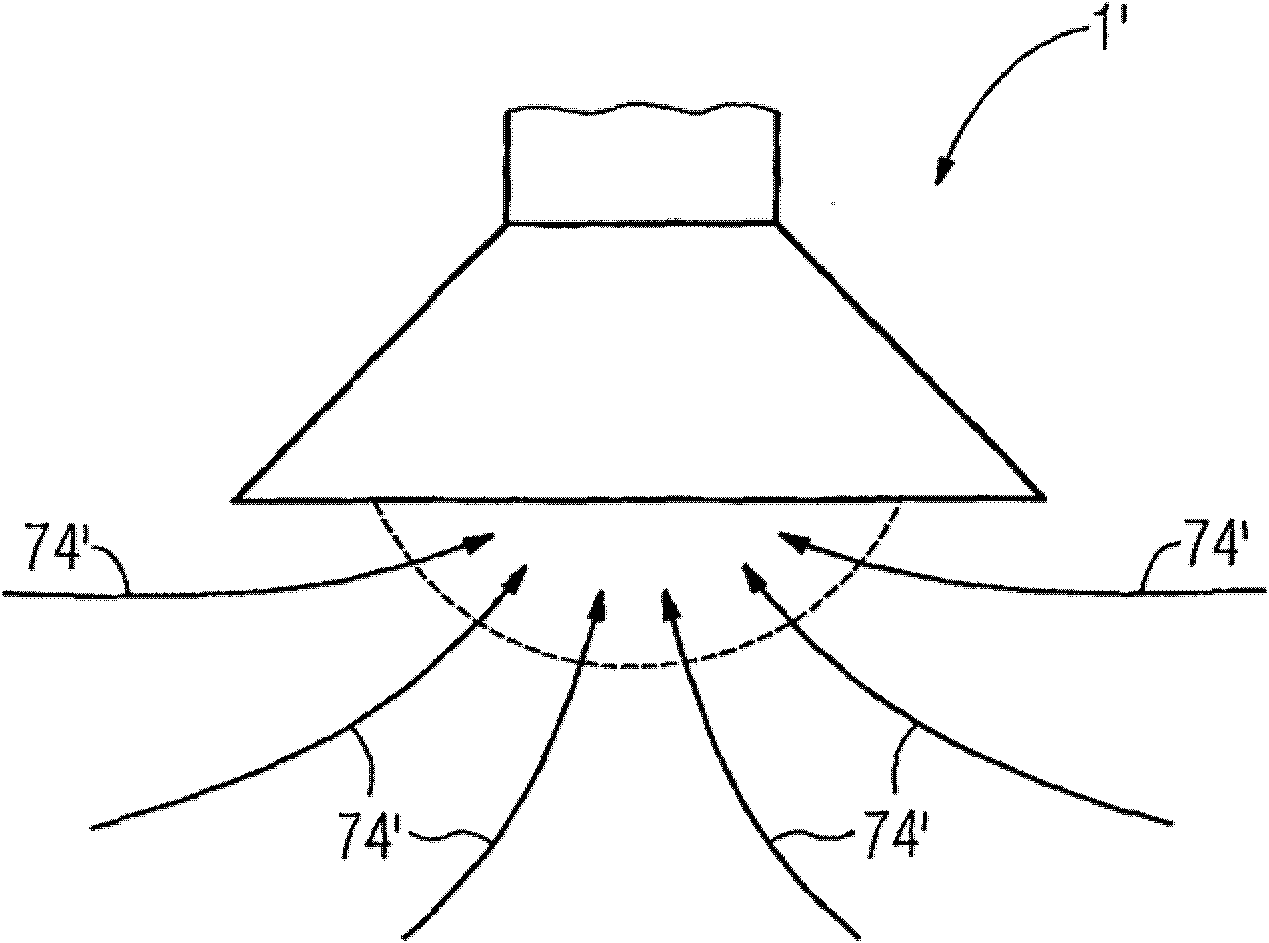

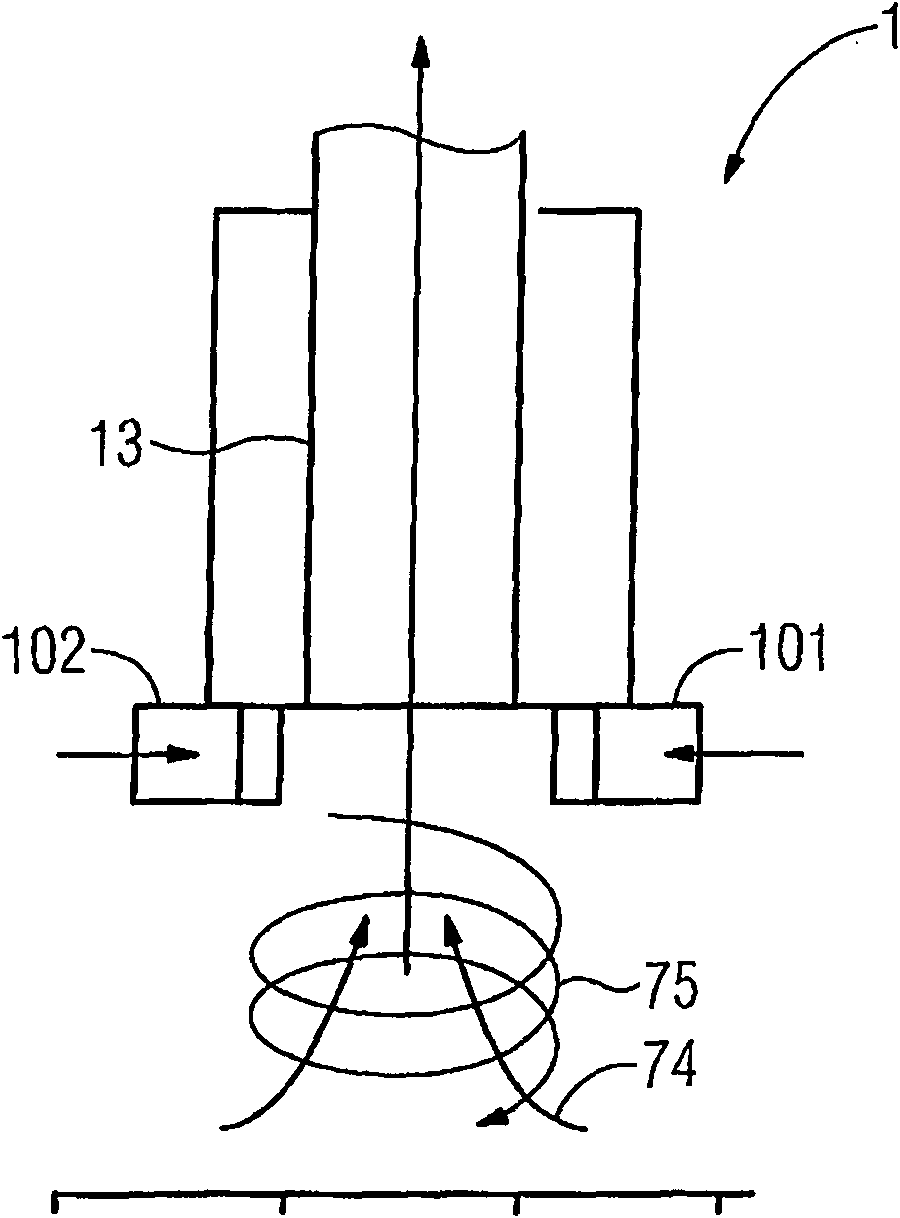

[0036] Figure 1c The concept of the cyclone suction hood 1 is briefly shown. Arrow 75 indicates a rotating air column and arrow 74 indicates suction ventilation. The combination of these two flows creates a cyclone. Air is sucked in through the air inlets 101 , 102 and thus pushed into the suction channel 13 .

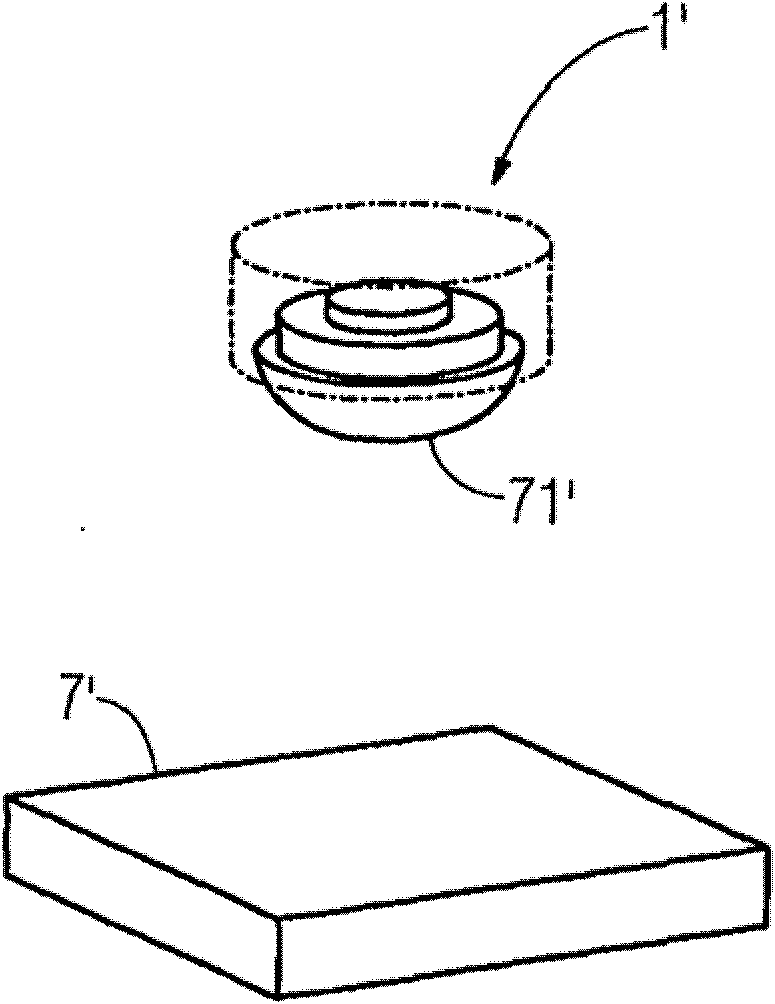

[0037] Figure 1d The pressure field 71 of such a hood system 1 is shown in . The pressure field represents the effective suction volume of the hood. The vortex created between the cooktop 7 and the hood 1 will draw the smoke from the cooktop 7 in a spiral motion.

[0038] figure 2 A suction hood 1 according to the invention is shown, which is arranged in a housing 18 . A vortex generator 10 is arranged at the lower end of the housing 18, and suction channels 131, 130 extend from the vortex generator to an opening at the top. In the lower part 131 , the suction channel has an upwardly narrowing conical shape, whereas in the upper part 130 the suction channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com